A multifunctional five-axis manipulator workstation

A mechanical arm and multi-functional technology, applied in the field of robotics, can solve the problems of low control precision and low degree of freedom of the end effector, achieve the effect of flexible and comprehensive printing work, reduce secondary processing, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

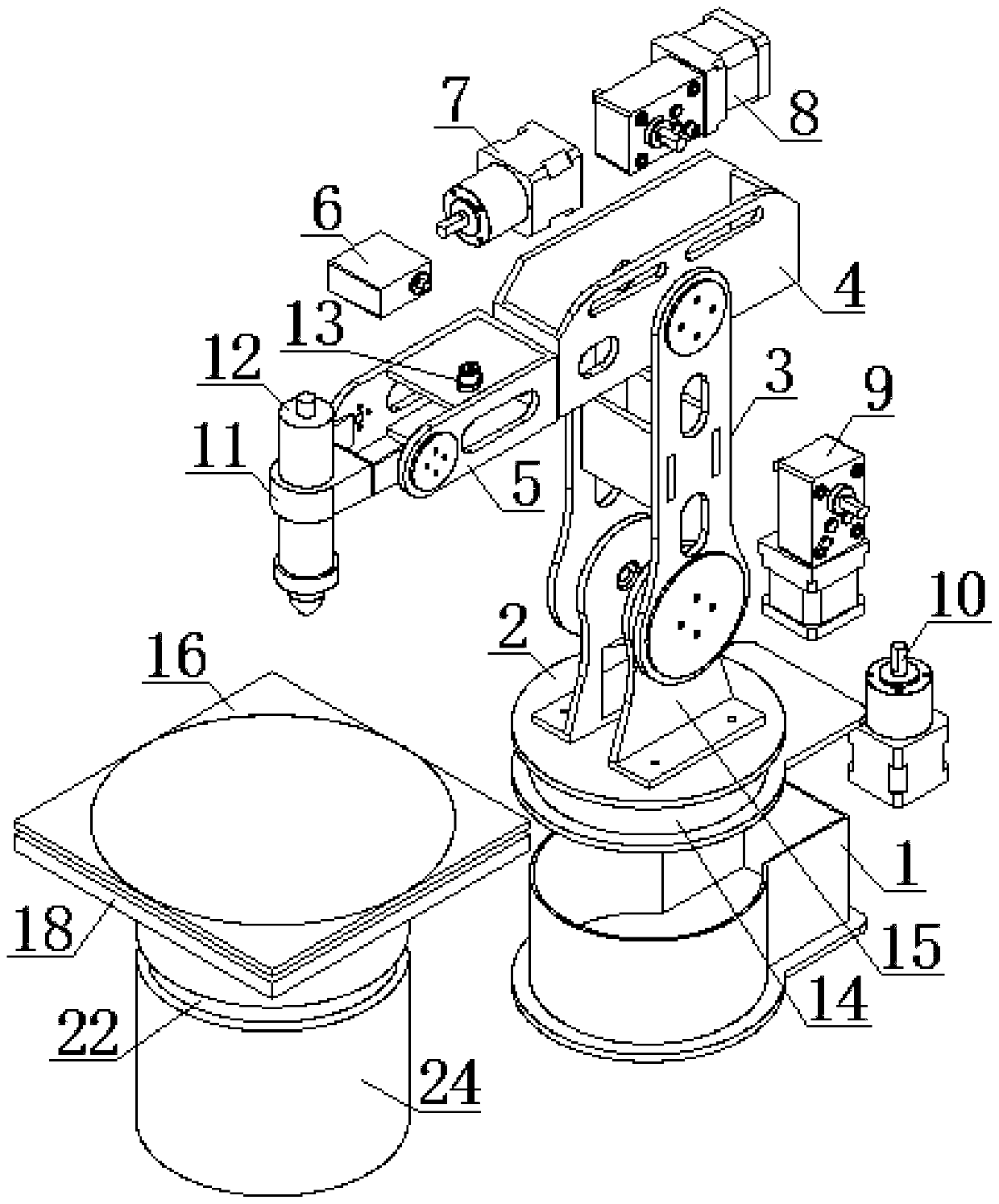

[0034] A multifunctional five-axis robotic arm workstation, such as Figure 1 to Figure 5 As shown, it includes a base 1, a rotary table 2, a rear arm 3, an intermediate arm 4, a forearm 5, and an end effector 12. A second planetary gear reducer 10 is fixedly connected in the base 1. Between the rotary table 2 and the base 1 A thrust ball bearing 14 is installed, the output shaft of the second planetary gear reducer 10 is fixedly connected with the turntable 2 through the flange, and a bracket 15 is fixedly connected to the top of the turntable 2, and the second planetary gear reducer 10 drives the bracket 15 Turn horizontally on base 1. The second worm gear reducer 9 is fixedly connected in the bracket 15, and the bottom of the rear arm 3 is fixedly connected with the output shaft of the second worm gear reducer 9 through a flange, so that the rear arm can rotate vertically on the bracket 15. The middle arm 4 is fixedly connected with the first worm gear reducer 8 and the fi...

Embodiment 2

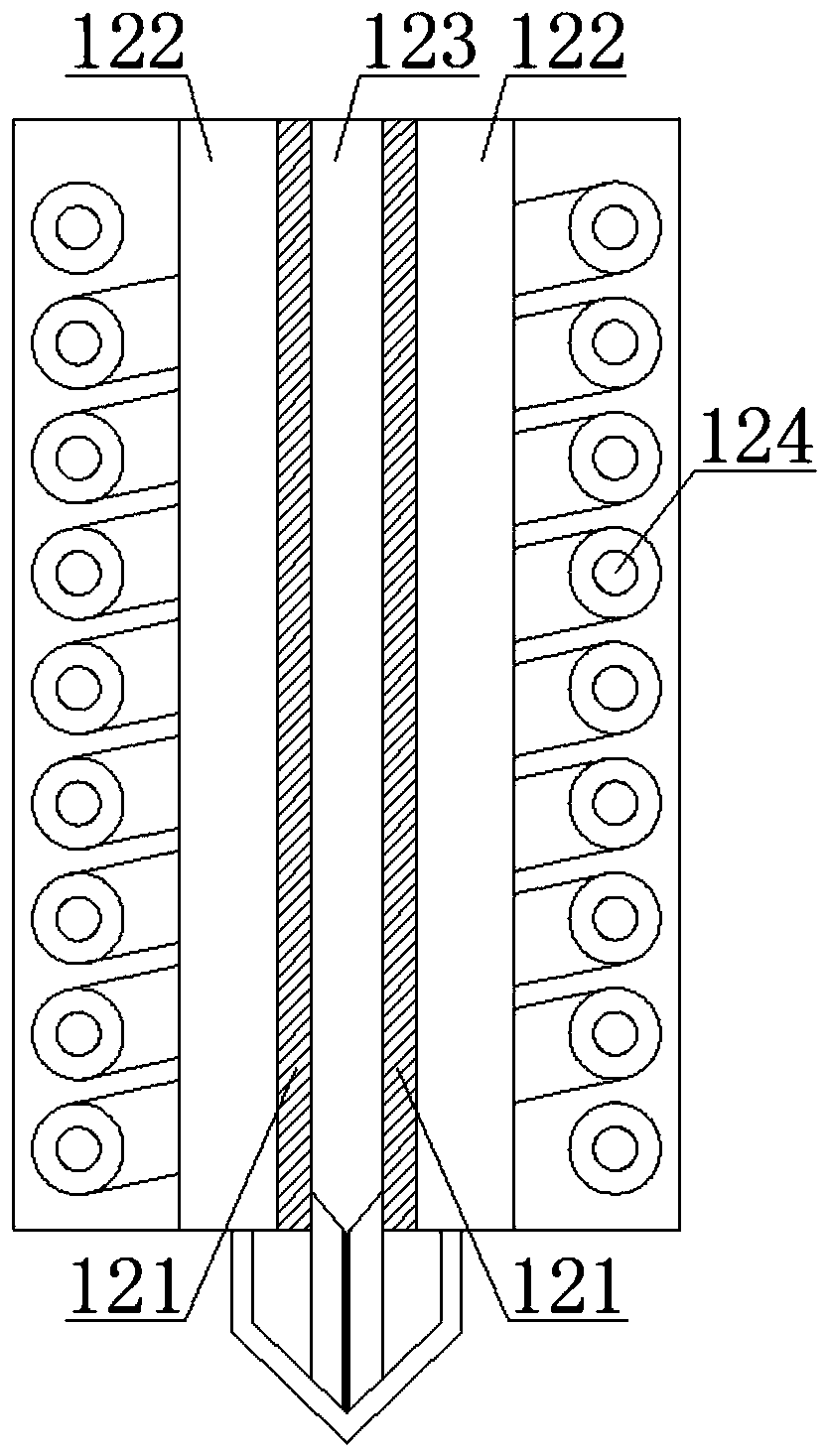

[0038] This embodiment is further improved on the basis of the above embodiments, such as figure 2 As shown, when the end effector 12 is a metal print head, a graphite tube 121 is provided outside the material tube 123 in the metal print head, a shielding gas channel 122 is provided on the outside of the graphite tube 121, and a shielding gas channel 122 is wound on the outside of the shielding gas channel 122. The induction coil 124 is driven by an external ZVS switch circuit. The circuit diagram of the ZVS switch circuit is shown in Figure 5 As shown in the figure, L1 and L2 are respectively connected to the induction coil 124, the induction coil is made of copper wire, and ±48V is connected to the power supply, and the high-efficiency intermediate frequency induction inverter is realized through the ZVS switching circuit, and the graphite tube 121 passes through its own The induced current generates Joule heat, which melts the material quickly, and the liquid metal is ex...

Embodiment 3

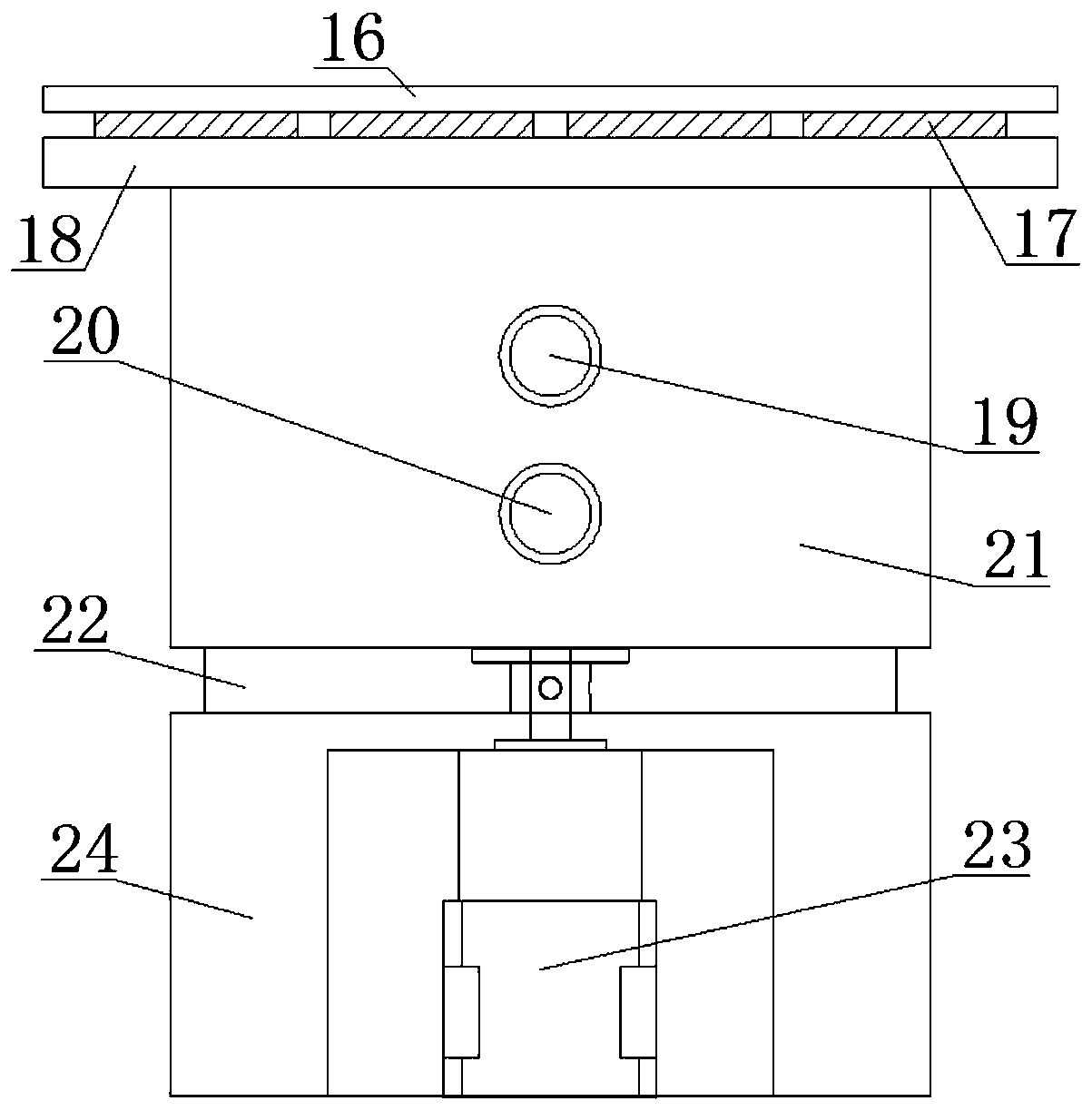

[0040] This embodiment is further improved on the basis of the above embodiments, such as image 3 , Figure 4 As shown, a water cooling device is provided below the metal print head, and the water cooling device includes a semiconductor cooling chip 17, a water cooling tank 21 and a copper tube 25. The top of the semiconductor cooling chip 17 is provided with a heat absorbing platform 16, and the bottom of the semiconductor cooling chip 17 is provided with The heat-absorbing bottom plate 18 and the side wall of the water-cooling tank 21 are provided with a water inlet 19 and a water outlet 20 respectively. , The water outlet 20 is sealed and connected. A water-cooling base 24 is also provided below the water-cooling tank 21, and a third planetary gear reducer 23 is fixedly connected in the water-cooling base 24. A b thrust ball bearing 22 is installed between the water-cooling tank 21 and the water-cooling base 24, and the third planetary gear The output shaft of the speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com