Gravity type sludge dehydration device

A technology of sludge dewatering and dewatering device, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problems of complicated operation control process, high engineering cost, poor cost performance of the device, etc. The effect of low maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

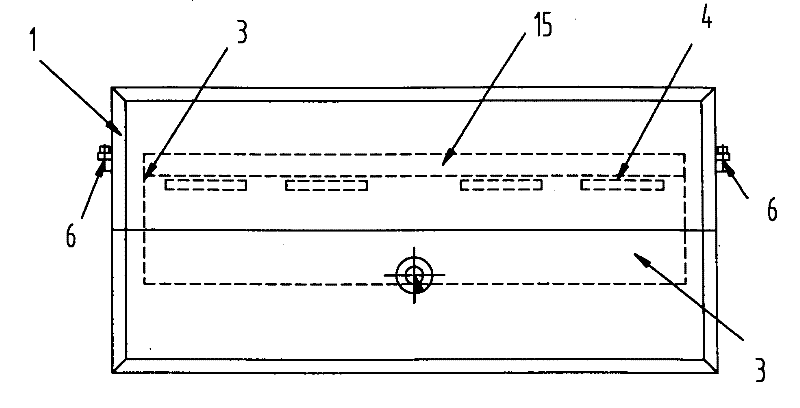

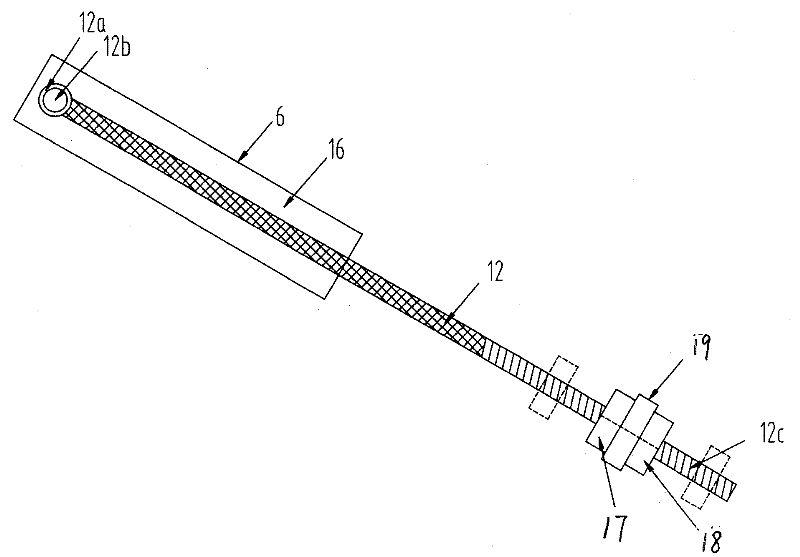

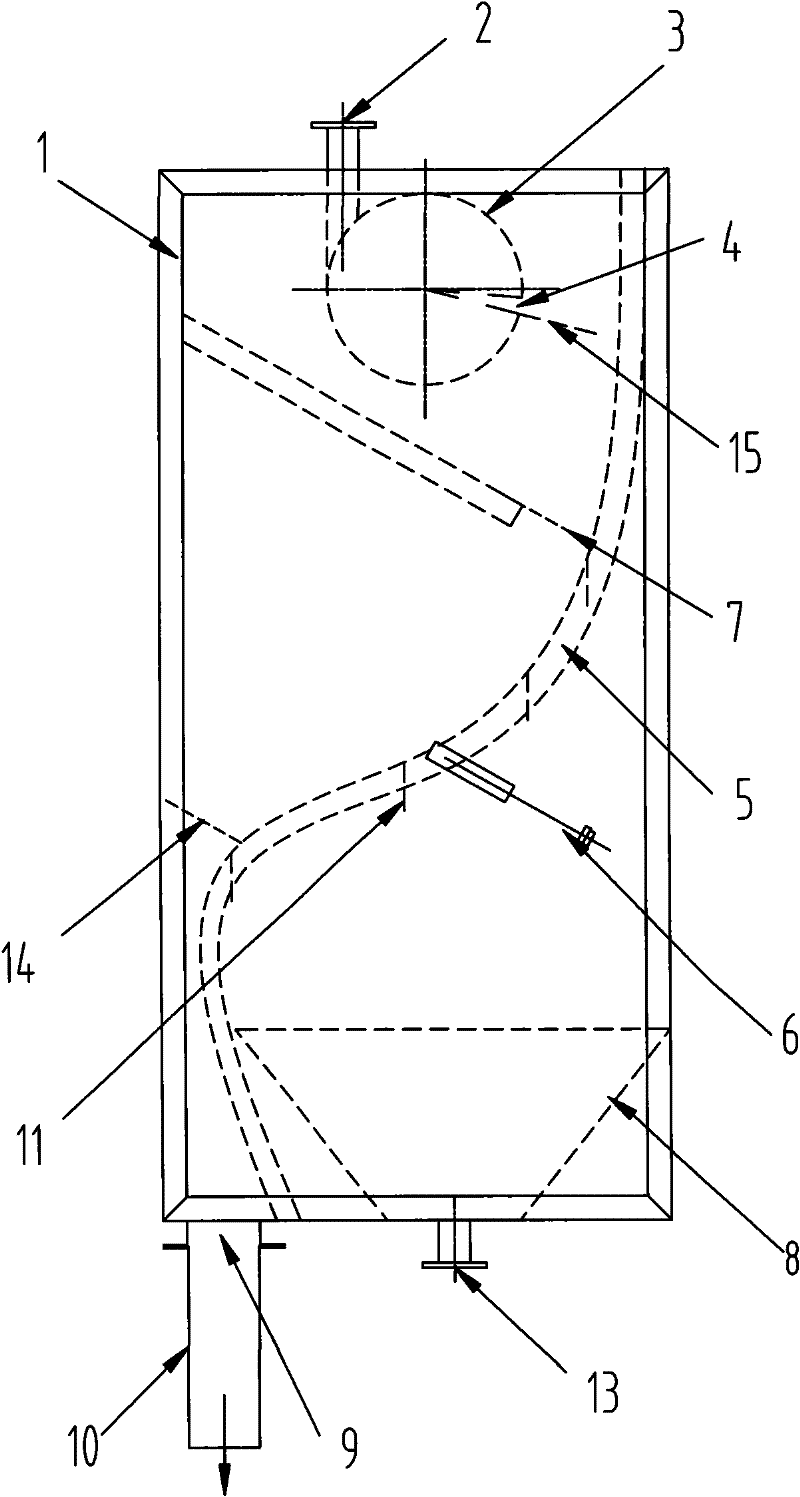

[0017] Such as figure 1 , figure 2 and image 3 As shown, the present invention discloses a gravity sludge dewatering device, which includes a housing 1, a water inlet pipe 2 is arranged above the housing, a drain pipe 13 and a sludge discharge pipe 9 are arranged below, and a dewatering device 5 is connected to the housing. From the top to the bottom, the inner cavity of the shell 1 is divided into a water purification area and a mixing area. In the mixing area, there is a mixing and distributing cylinder 3 with a circular cross-section communicating with the water inlet pipe 2 from top to bottom, and a first water baffle 7 , the second water retaining plate 14, the mud discharge pipe 9 is communicated with the lower end of the mixing area; the water collecting area is provided with a water collecting bucket 8, and the drain pipe 13 is communicated with the lower end of the water collecting bucket 8; the water inlet pipe 2 is connected with the mixing distribution cylinder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com