Liquid-crystalline polymer composition containing nanostructured hollow-carbon material and molded article thereof

A liquid crystal polymer, nanostructure technology, applied in the field of its molded products, can solve the problems of warpage of molded products, adverse effects on component performance, warpage, etc., and achieve the effects of light weight, reducing anisotropy, and suppressing warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The method for preparing the catalyst solution or catalyst suspension is characterized in that the solubility of the catalyst composite in the catalyst solution or the dispersibility of the catalyst composite in the catalyst suspension can be changed by changing the molar ratio between the dispersant to be used and the catalyst precursor Than to control. The molar ratio of catalyst atoms to polar groups in the dispersant may be about 0.01 to 100, preferably about 0.05 to 50.

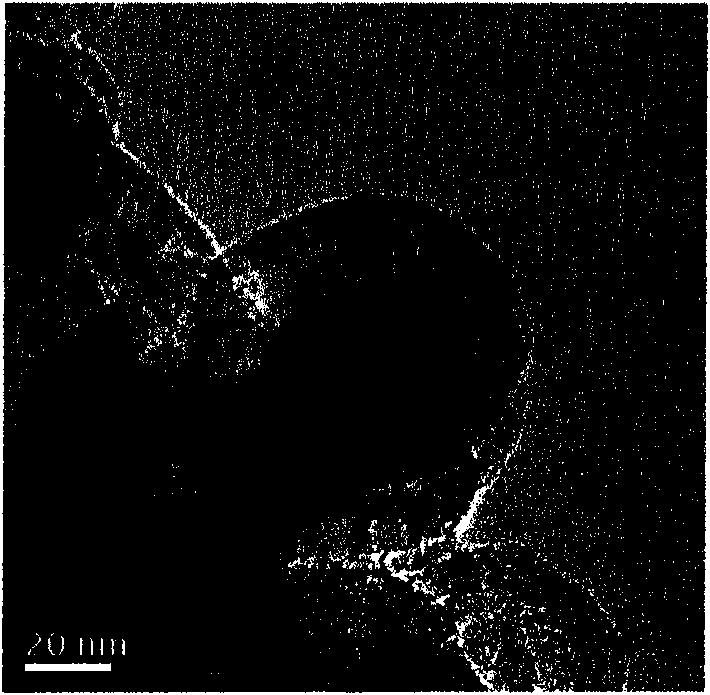

[0040]Dispersants promote the formation of catalyst nanoparticles with a very small and uniform particle size. In the presence of a dispersant, catalyst nanoparticles having a size of about 1 μm or less can be formed. The particle size may be about 100 nm or less, more preferably about 50 nm or less. The particle diameter corresponds to the size of the hollow portion of the obtained nanostructured hollow carbon material. That is, the diameter of the hollow portion size of the resulting nanostru...

Embodiment

[0124] The present invention is described in more detail by the following examples, but these examples should not be construed as limiting the scope of the present invention.

[0125] The evaluation methods for the liquid crystal compositions or molded articles obtained in Examples are as follows.

[0126] Molding shrinkage:

[0127] A flat mold shrinkage measurement sample having a film gate having a thickness of 1 mm and a size of 64 mm×64 mm×3 mm was obtained by molding the liquid crystal polymer composition using an injection molding machine. The lengths of the sides of the specimen in directions parallel (MD) and perpendicular (TD) to the flow direction were measured and calculated by using the ratio of the molded article size to the mold size. More specifically, the mold shrinkage rate is calculated by the following expression. Molding shrinkage rate = (mold size - molded product size) / mold size × 100 (%)

[0128] proportion;

[0129] As a specific gravity measurem...

preparation example 1

[0133]

[0134] A 0.1 M iron mix solution was prepared by using 2.24 g of iron powder, 7.70 g of citric acid and 400 ml of water, filled into an airtight container, and then mixed using a benchtop shaker for 7 days. During mixing, the generated hydrogen gas was properly vented from the vessel to obtain a catalyst nanoparticle mixture solution. 100 ml of the catalyst nanoparticle mixture solution was added to the mixture solution of 6.10 g of resorcinol and 9.0 g of formaldehyde, and 30 ml of ammonium aqueous solution was added dropwise under vigorous stirring. The pH of the resulting suspension was 10.26. The suspension was aged by heating to 80° C. to 90° C. on an oil bath for 3.5 hours to provide a carbon material intermediate. The carbon material intermediates were collected by filtration, dried in an oven overnight, and then sintered at 1150 °C for 3 h under a nitrogen atmosphere. The composite material of the nanostructure obtained was refluxed in 5M nitric acid solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com