Processing method of lithography machine silicon slice alignment signals

A technology of silicon wafer alignment and processing method, which is applied in the direction of microlithography exposure equipment, photolithography exposure equipment, etc., and can solve the problems of large alignment errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

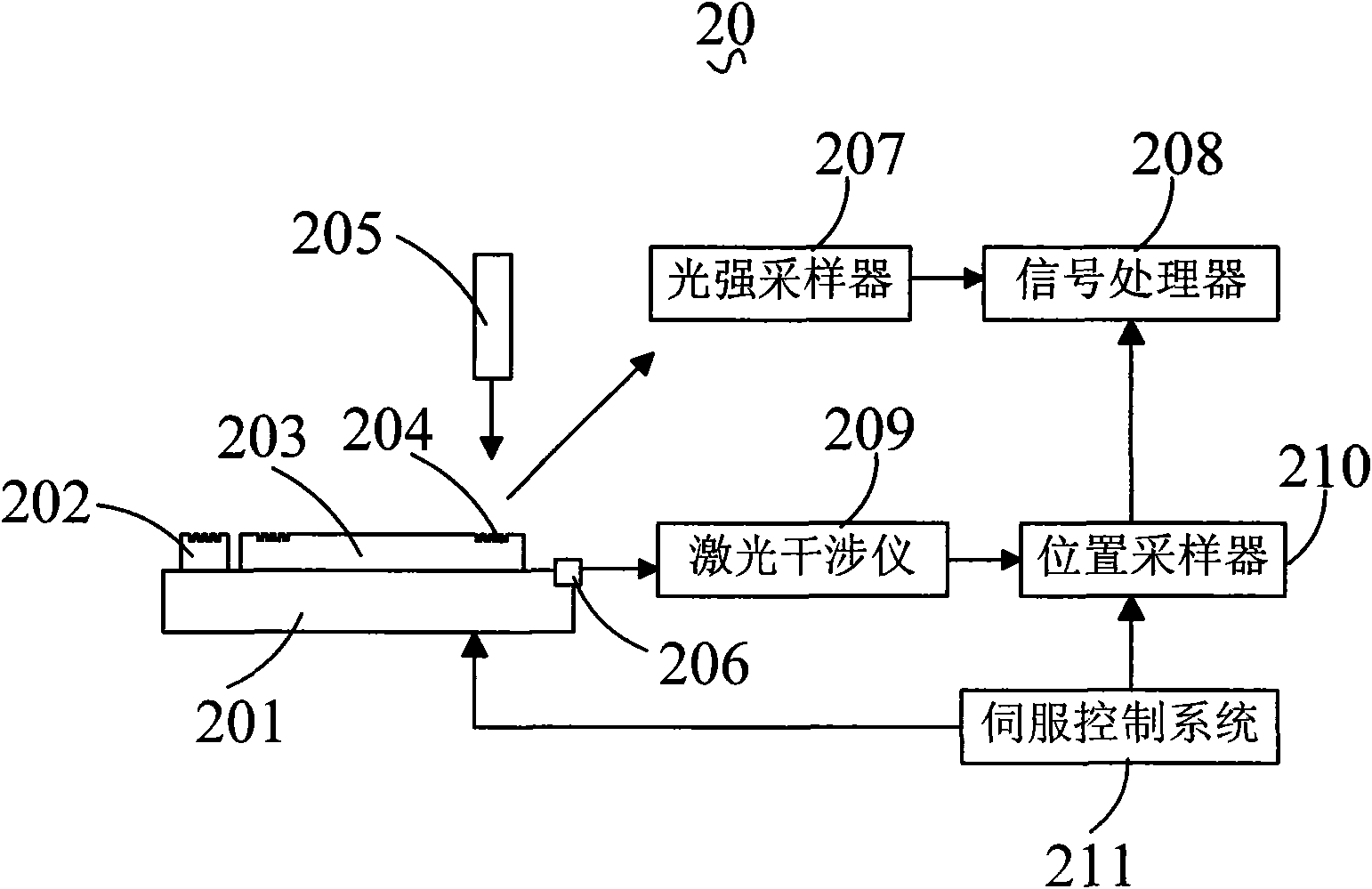

[0028] see figure 2 . A schematic diagram of a silicon wafer alignment system of a photolithography machine using the method for processing silicon wafer alignment signals of a photolithography machine according to the present invention. The silicon wafer alignment system 20 of the lithography machine includes a workpiece table 201, which can freely reciprocate in the horizontal direction; a reference plate 202 and a silicon wafer 203 attached to the workpiece table 201; 202 and the alignment marks 204 on the silicon wafer 203; a laser light source 205 for providing alignment illumination; a light intensity sampler 207 for converting the alignment optical signal into a digital electrical signal; for determining the position of the workpiece table 201 The mirror ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com