Method and device for processing dried waxberries

A processing method and fruit technology, applied in the field of dried bayberry fruit processing, can solve problems such as loss, impact on the environment, loss of bayberry nutrients, etc., and achieve the effect of reducing the loss of nutrients and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The invention discloses a processing method of dried red bayberry, which is characterized in that:

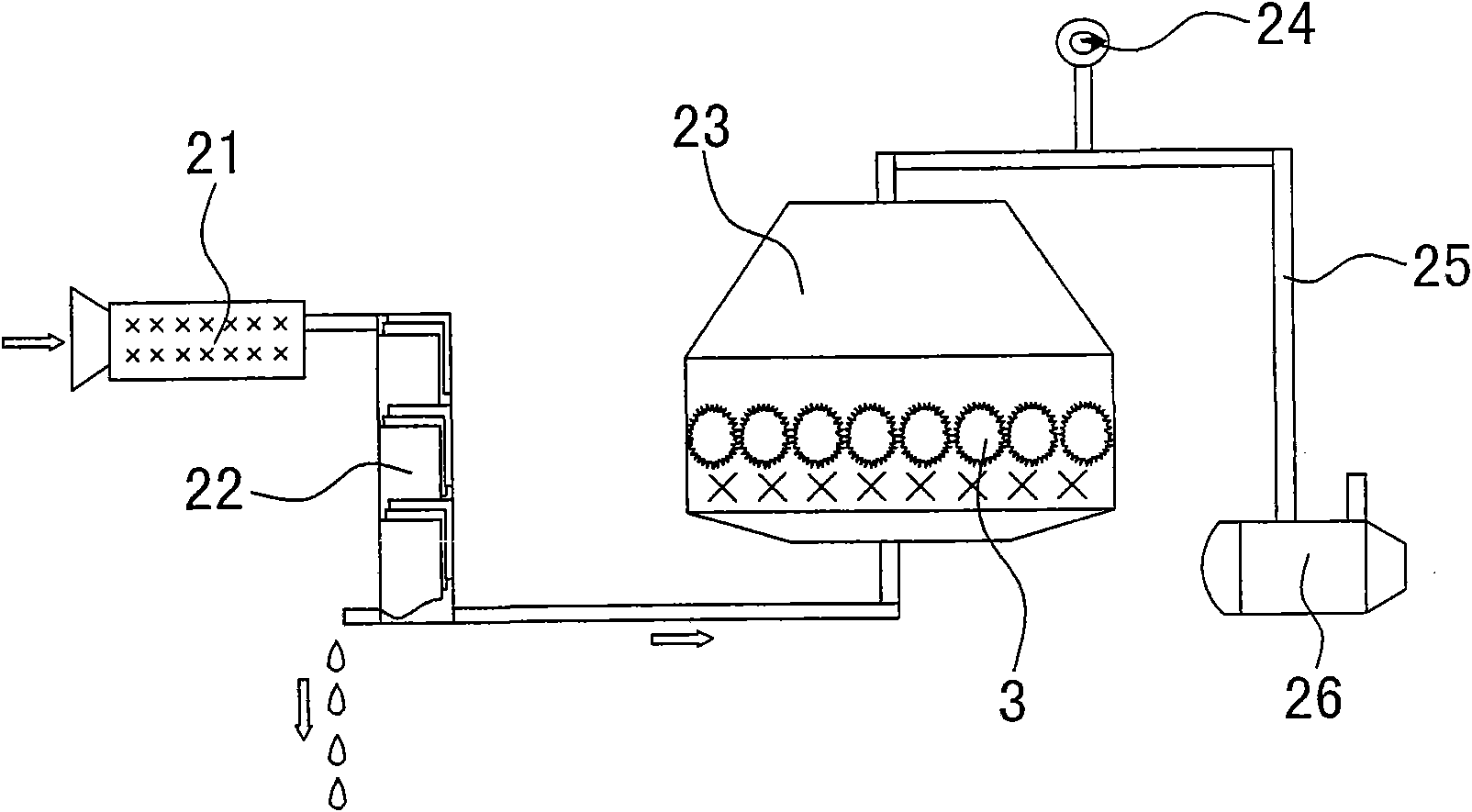

[0019] a. Clean the fresh red bayberry fruit with cleaning solution, soak it in a liquid composed of water, hardener, food glue, flavoring agent, anti-mold agent, sugar, etc., soak and absorb sugar for 30 minutes under the pressure of -0.05~-0.1MPa ~50min (according to the size of bayberry fruit);

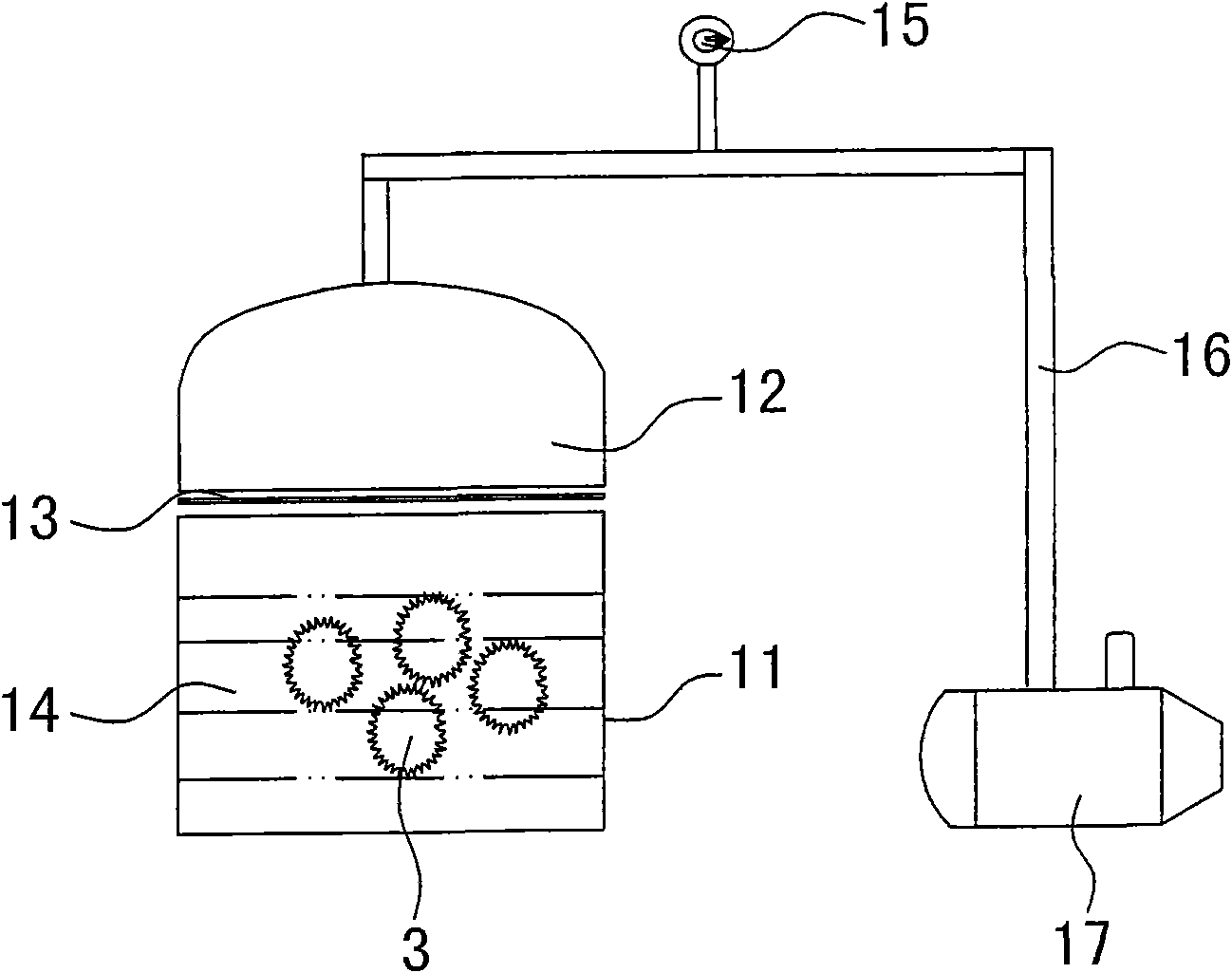

[0020] b. Put the sugar-absorbed red bayberry fruit in the drying machine, and dry it until the water content reaches below 25% at 50-80°C and 0-0.05MPa (generally -0.03--0.05Mpa) vacuum degree;

[0021] c. Spray the dried red bayberry into a certain amount of spices, mix well, and then pack it in a vacuum, which is the finished product.

[0022] In the processing method of dried red bayberry fruit of the present invention, the first step adopts the vacuum sugar absorption method to extract the internal gas of red bayberry, and sends the sugar glue liquid into the inside of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com