High vacuum exhaustion laser sealing device and process of micro-infrared detector

A technology of infrared detectors and sealing devices, applied in laser welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of sealing and clamping, and achieve the effects of convenient use, reliable implementation space, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific embodiment of the present invention is described in further detail below in conjunction with accompanying drawing:

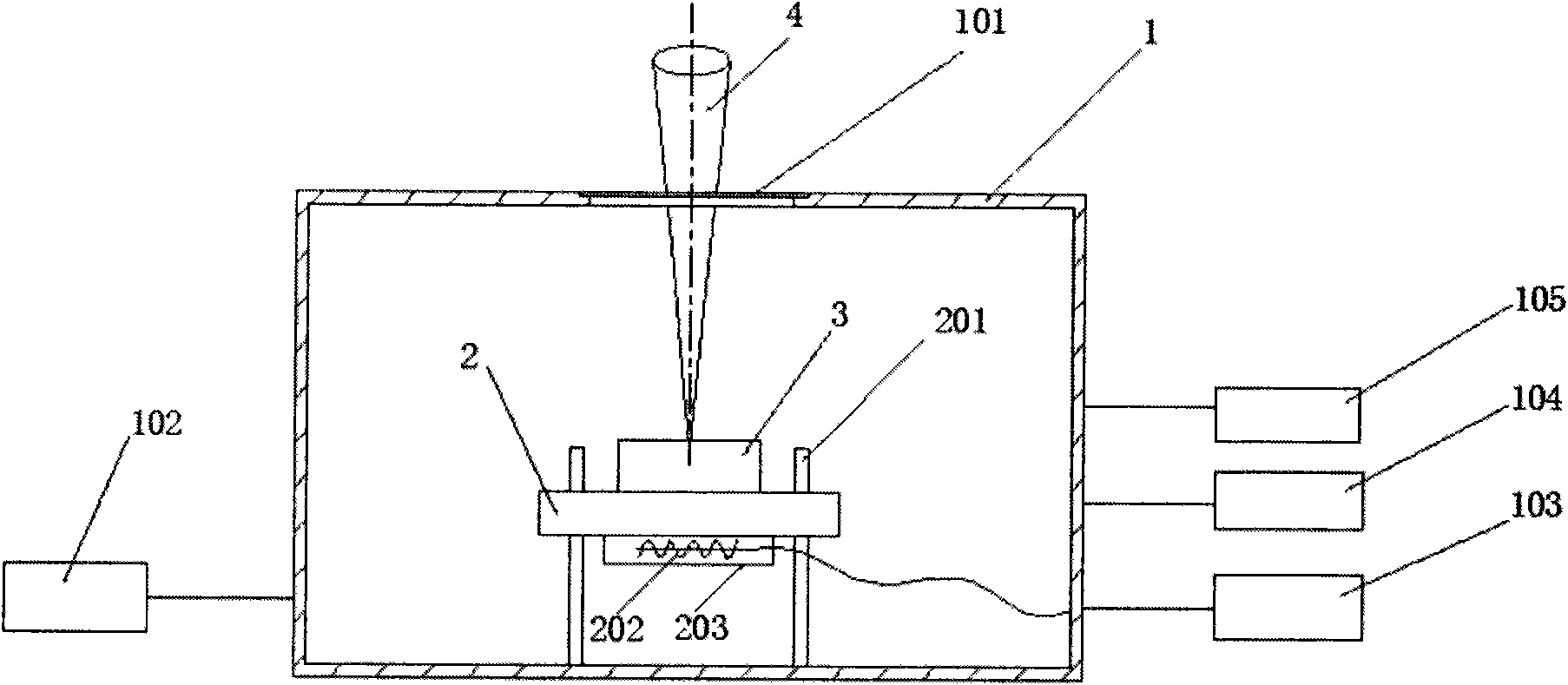

[0035] The high-vacuum baking exhaust device of the present invention includes: an outer casing 1, a sample stage 2, a support column 201, a heating ring 202, a vacuum maintaining system, and the like.

[0036] Fix the sample 3 on the sample stage 2 in the vacuum chamber. The heating ring 202 close to the bottom of the sample stage 2 is connected to the circular stainless steel fixing groove 203 through four bolts. In order to slow down the heat transfer, the three support columns 201 fixed on the bottom of the outer casing 1 are made of tetrafluoroethylene, and used to support the sample stage 2. After adjusting to a suitable height, the sample stage 2 and the support columns 201 are fixed with nuts.

[0037] Then, close the tempered glass airtight door, use the TURBOVAC-50K high vacuum molecular pump exhaust unit to connect the exhaust por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com