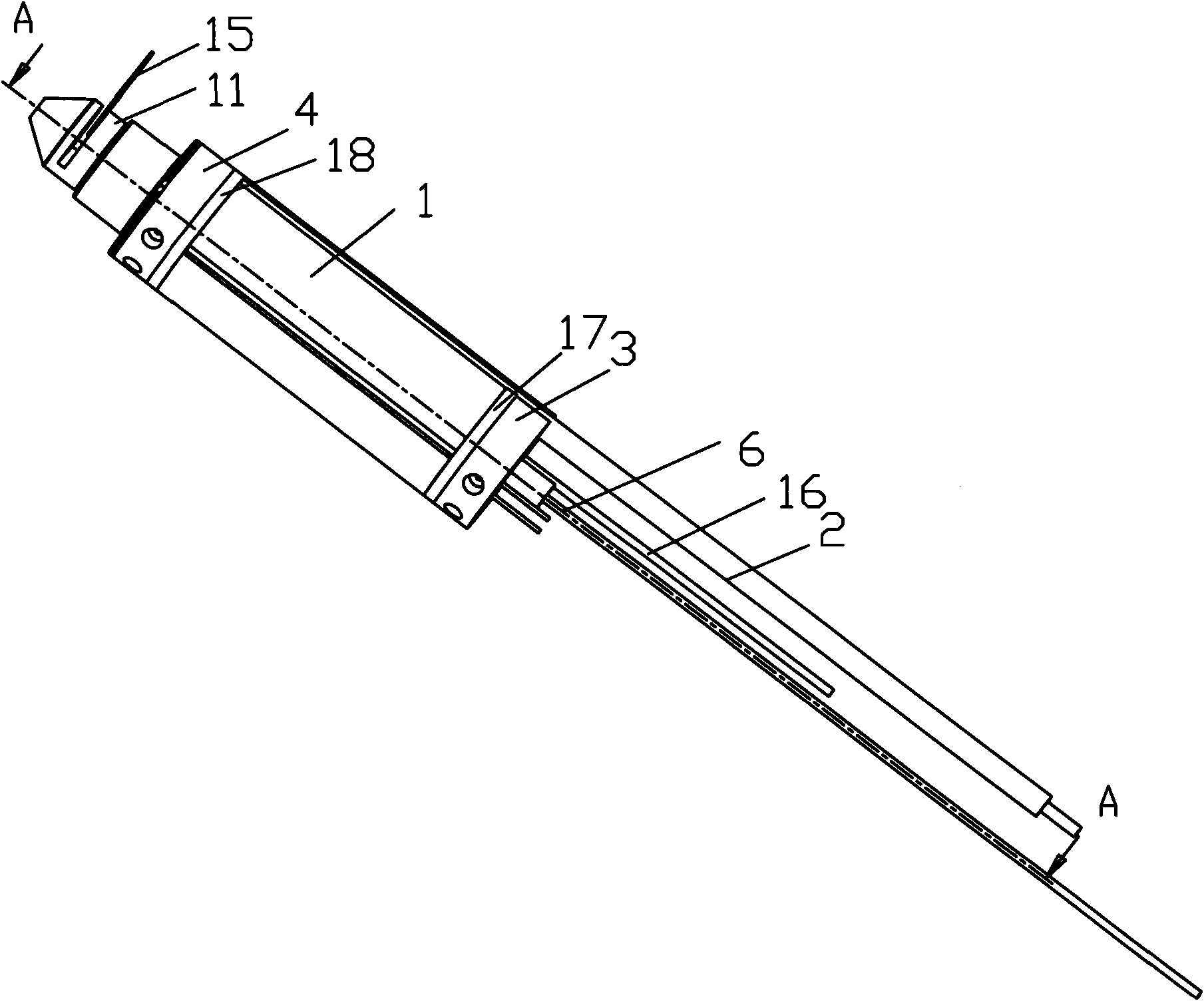

Electron beam evaporation source device

An electron beam evaporation and source device technology, applied in vacuum evaporation plating, ion implantation plating, metal material coating process, etc., can solve the problems of complex equipment structure, high price and high cost, and achieve cost reduction and cost reduction , reliable and easily adjustable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

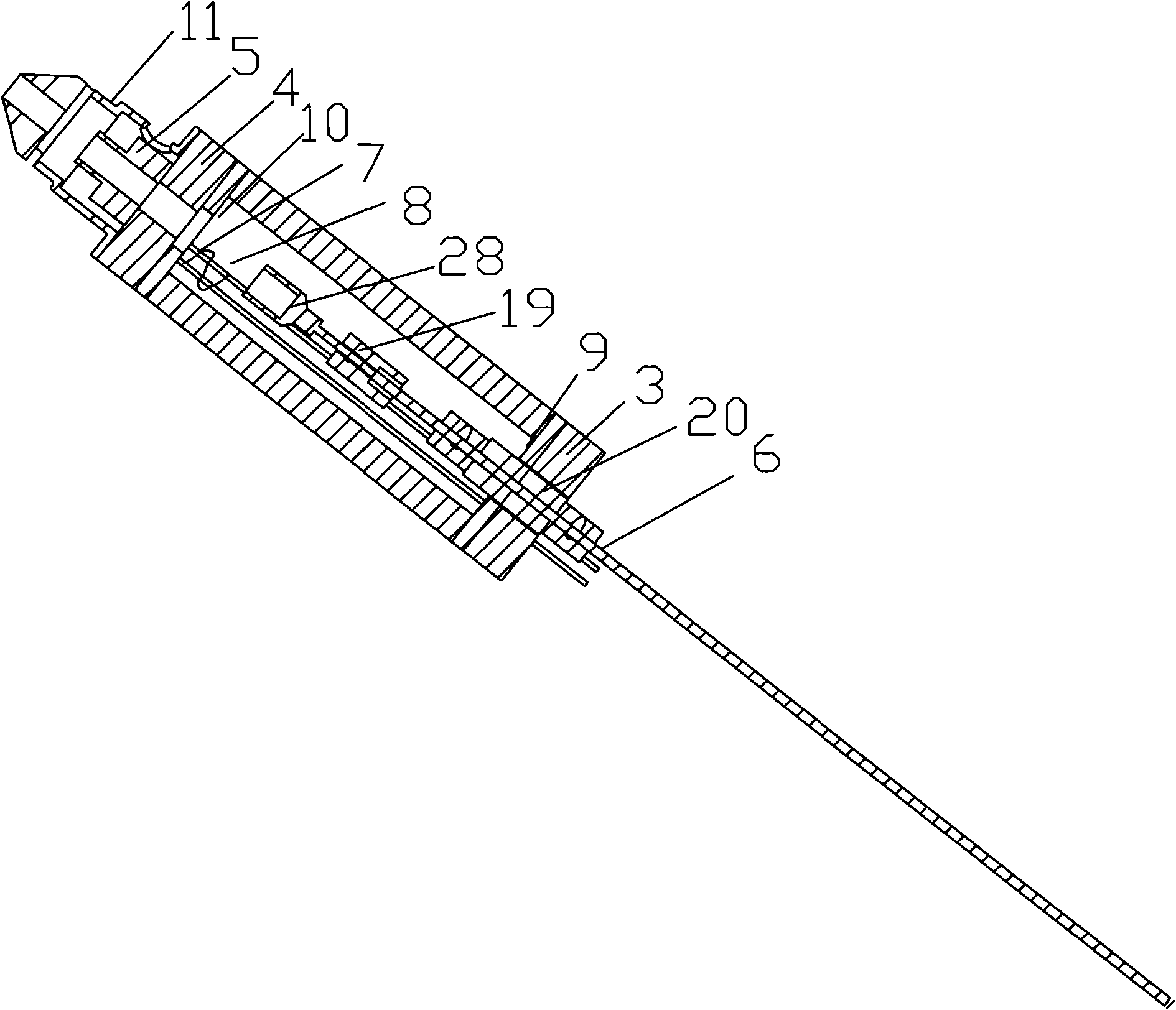

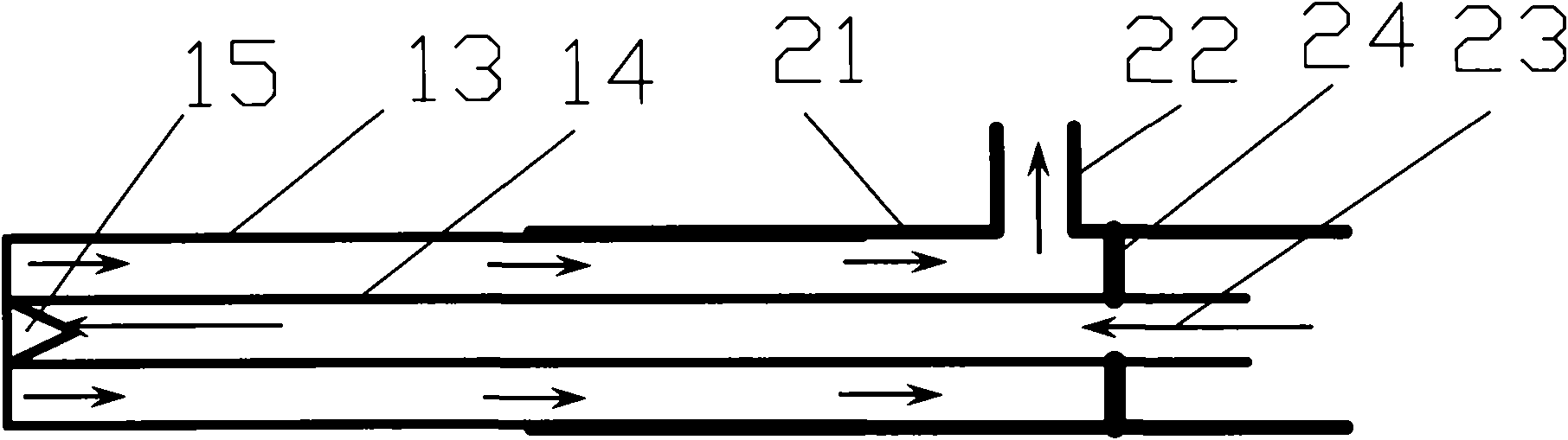

[0046] More specifically, when the present invention is implemented, if the electron beam evaporation source device is connected to the multi-port flange for ultra-high vacuum, an ultra-high vacuum multi-pin electronic wire connector is installed on the multi-port flange for feeding The high voltage of the material to be evaporated is connected to the ultra-high vacuum high-voltage wire connector, the cooling water inlet and outlet, that is, the connecting pipe, and the rotating device connected with the control rod 16 to control and close the baffle. The front end of the shell is fixed with a stainless steel collector shell with a middle hole and an ion beam collector. Two insulating ceramic covers are installed at both ends of the cylindrical shell, and the central part of the insulating ceramic covers at both ends is provided with multiple perforations. , from the perforation through the metal rod providing high voltage and the molybdenum rod wire connected to the heating fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com