Production method for co-production of mirabilite and salt and production device thereof

A production method and technology for co-production of nitrates, applied in chemical instruments and methods, alkali metal sulfites/sulfites, alkali metal compounds, etc., can solve the waste of resources, the discharge of mother liquor, and the inability to recover the discharged waste liquid To achieve the effect of improving the utilization rate of mineral resources, improving energy conservation and emission reduction, and ensuring sustainable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The following is a non-limiting example of the invention to illustrate the invention in detail.

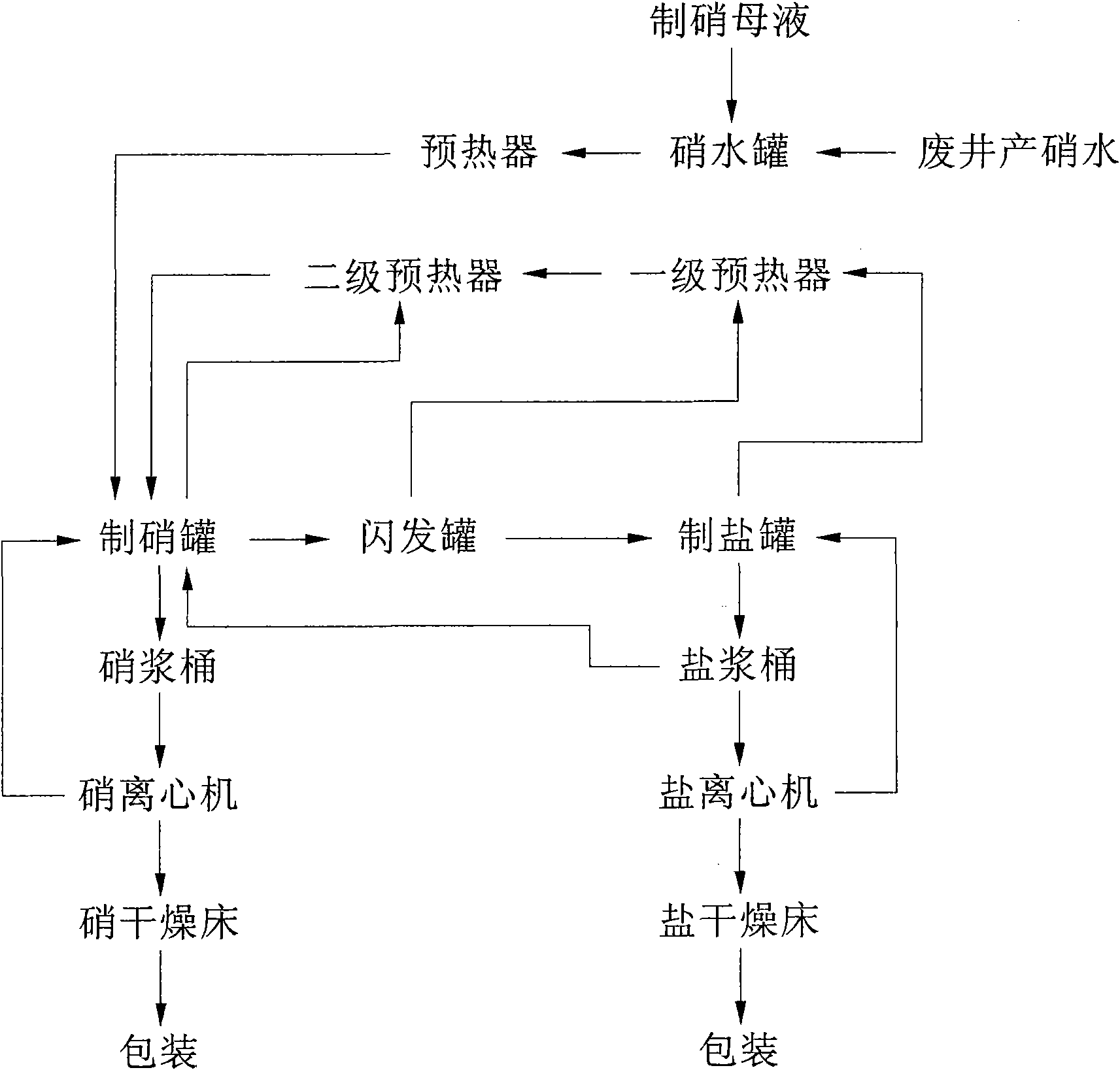

[0052] figure 1 It is a schematic flow chart of the production process of the present invention, which embodies the steps included in the nitrate cogeneration production method of the present invention.

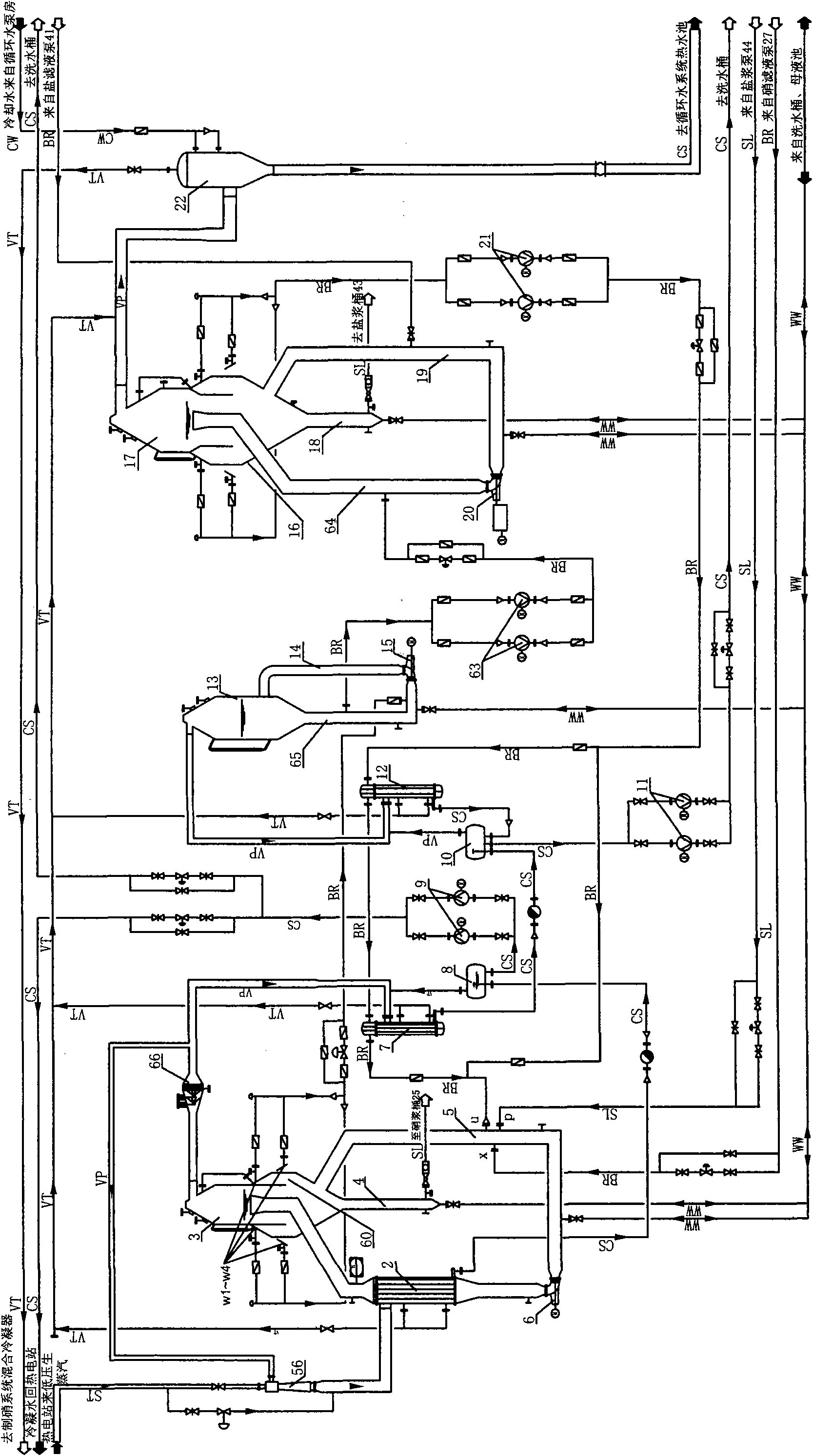

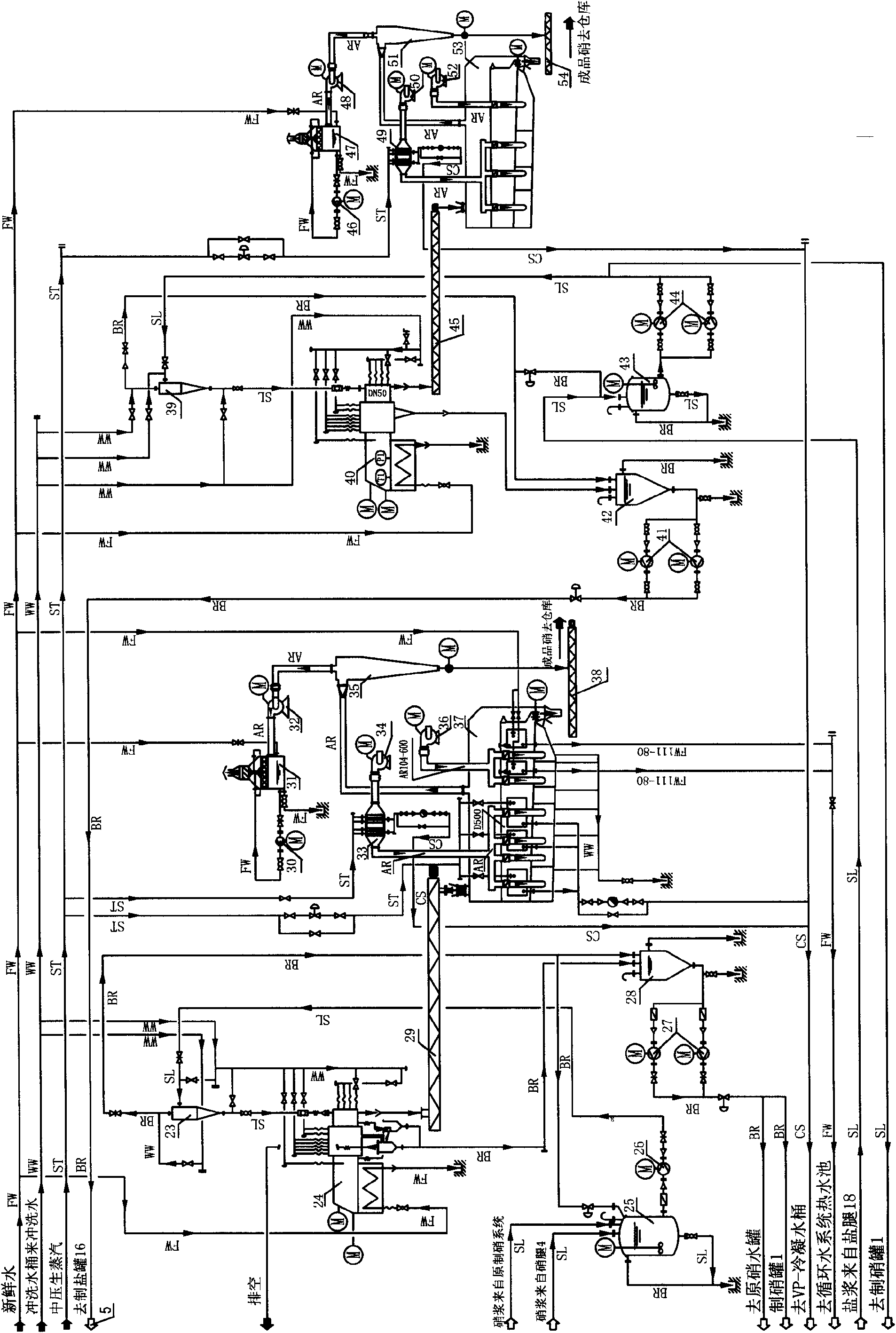

[0053] figure 2 with image 3 It is a production device diagram of the present invention. The nitrate-salt cogeneration production device includes a nitrate making tank 1, a nitrate slurry tank 25, a nitrate separation device, a nitrate drying device, a flash tank 13, a salt making tank 16, a salt slurry tank 42, a salt separation device, and a salt drying device, wherein Nitrate making tank 1, nitrate slurry tank 25, nitrate separation equipment, and nitrate drying equipment are connected in sequence, flash tank 13, salt making tank 16, salt slurry tank 42, salt separation equipment, and salt drying equipment are connected in sequence, and salt slurry tank 42 is also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com