Industrial Clean Production Process of Captan

A technology of clean production and captan, applied in the field of pesticides, can solve problems such as low yield, inoperability of workers, strong odor, etc., and achieve the effect of high product yield, simple operation process and process method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

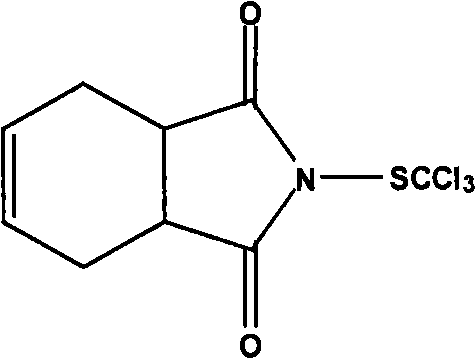

Image

Examples

Embodiment 1

[0014] Add 150 milliliters of water to a 250 milliliter four-necked bottle equipped with a stirrer, a thermometer and a dropping device. Start stirring and add 9.0 grams (content 96.0%) sodium hydroxide (or replace with 30.0-50.0wt% liquid sodium hydroxide) to dissolve, then add 30.0 grams (content 98.0wt%) 1,2,3,6-four The hydrophthalimide was dissolved for 0.5 hour, and 37.5 g (content 98.0 wt%) of trichlorothiochloromethane was added dropwise at 0-30° C., and kept for 2.0 hours. The acidity of the reaction material indicated the end of the reaction. The material is transferred to a purifying and temperature-intensive treatment kettle, heated to 50-60° C., kept for 3.0 hours, then cooled to 20° C., filtered, washed twice with 20 ml of water, and dried to obtain the original drug of captan. Yield 89.8%; Content 97.1wt% (Japan Shimadzu high performance liquid chromatograph external standard method quantification; Standard product captan fusing point is 178 ℃); Trichlorothiochl...

Embodiment 2

[0016] Add 150 milliliters of water in a 250 milliliter four-necked bottle equipped with stirrer, thermometer and dropping device, add 34.4 grams (content 98.0wt%) 1,2,3,6-tetrahydrophthaloyl under stirring Sodium, after dissolving, add 37.5 g (content 98.0wt%) of trichlorothiochloromethane dropwise at 0-30° C., and keep warm for 2.0 hours. The acidity of the reaction material indicates the end of the reaction. Transfer the material to a purifying and heating treatment kettle, heat up to 50-60°C, keep the temperature for 3.0 hours, then cool down to 20°C, filter, wash twice with 20 ml of water, and dry to obtain the original drug of captan. Yield 90.02%; Content 97.2wt% (Japan Shimadzu high performance liquid chromatograph external standard method quantification; Standard product captan fusing point is 178 ℃); Trichlorothiochloromethane content below 0.01wt% (gas chromatography internal standard method Quantitative); THPI content 0.28wt% (Japan Shimadzu high performance liquid...

Embodiment 3

[0018] The temperature of the purified heat treatment of the reacted material in Example 1 was increased from 50-60° C. to 70-80° C., while other conditions remained unchanged, to obtain the original drug of captan. The yield is 88.5%, the content is 96.9wt%, the THPI content is 0.32wt%, the trichlorothiochloromethane content is less than 0.01wt%, and the sodium chloride content is 0.18wt%. (The detection method is the same as above)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com