Method for preparing proton exchange membrane fuel cell electrode with high catalyst utilization ratio

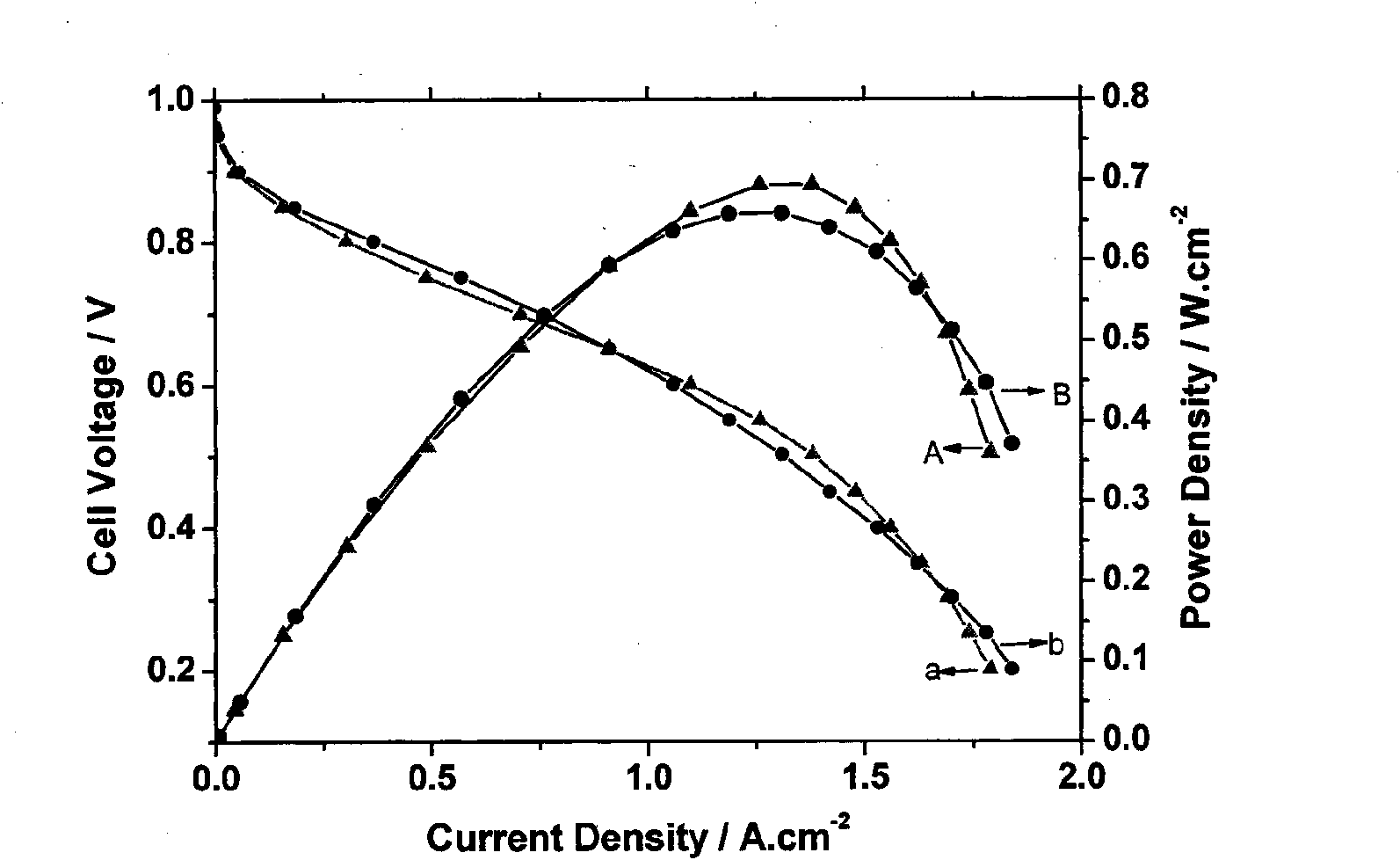

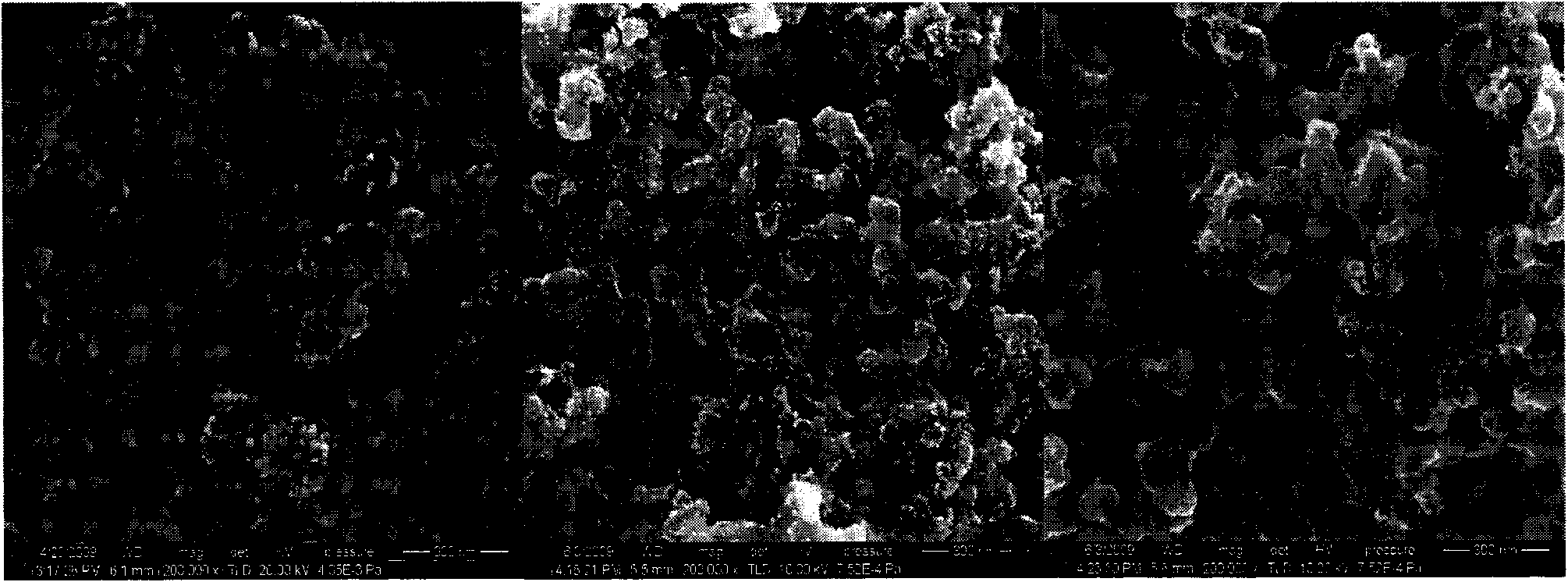

A fuel cell electrode, proton exchange membrane technology, applied in battery electrodes, circuits, electrical components, etc., to achieve the effect of low platinum loading, high electrocatalytic performance, and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Preparation of microporous layer

[0030] First, soak the carbon paper in an aqueous ethanol solution, oscillate for 30 minutes under ultrasonic conditions, and then soak it in a 30% polytetrafluoroethylene emulsion for 30 minutes, then place it in a muffle furnace at a temperature of 340°C and roast it for 40 minutes to obtain a hydrophobic Diffusion layer. Weigh PTFE and Vulcan XC-72 carbon powder according to the mass ratio of PTFE: Vulcan XC-72 carbon powder at 1:3, and then use ethanol as the solvent to oscillate uniformly under ultrasonic conditions, and apply multiple times On the hydrophobic diffusion layer, it was finally placed in a muffle furnace at a temperature of 340°C and fired for 45 minutes to obtain a microporous layer.

[0031] (2) Preparation of porous carbon electrode bonded with perfluorosulfonic acid resin

[0032] Weigh the perfluorosulfonic acid resin (mass concentration 0.5%) according to the mass ratio of perfluorosulfonic acid resin: Vulcan XC...

Embodiment 2

[0041] Step (1) is the same as step (1) in Example 1.

[0042] (2) Preparation of porous carbon electrode bonded with perfluorosulfonic acid resin

[0043] According to the mass ratio of perfluorosulfonic acid resin: Vulcan XC-72 carbon powder is 1:9, weigh the perfluorosulfonic acid resin (mass concentration is 0.5%), and then apply it to the micropores prepared in step (1) several times On the layer, the porous carbon electrode bonded with perfluorosulfonic acid resin was prepared by drying at 50°C.

[0044] (3) Preparation of catalytic electrode for proton exchange membrane fuel cell by ion exchange / electroreduction

[0045] The porous carbon electrode bonded with perfluorosulfonic acid resin prepared in step (2) is immersed in an aqueous solution of platinum dichlorotetraammine with a concentration of 0.5 mol / L, and immersed for 10 hours at 80°C. Clean with water. Then, a three-electrode system is adopted, with the ion-exchanged electrode as the working electrode, the platinum m...

Embodiment 3

[0048] Step (1) is the same as step (1) in Example 1.

[0049] (2) Preparation of porous carbon electrode bonded with perfluorosulfonic acid resin

[0050] According to the mass ratio of perfluorosulfonic acid resin: Vulcan XC-72 carbon powder is 1:1, weigh the perfluorosulfonic acid resin (the mass concentration is 0.5%), and then apply it to the micropores prepared in step (1) several times On the layer, the porous carbon electrode bonded with perfluorosulfonic acid resin was prepared by drying at 140°C.

[0051] (3) Preparation of catalytic electrode for proton exchange membrane fuel cell by ion exchange / electroreduction

[0052] The porous carbon electrode bonded with the perfluorosulfonic acid resin prepared in step (2) is immersed in an aqueous solution of platinum dichlorotetraammine with a concentration of 0.05 mol / L, and immersed for 0.5 hours at 10° C. Clean with water. Then, a three-electrode system is adopted, with the ion-exchanged electrode as the working electrode, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com