Under-mud shearing machine for Spartina anglica

A technology of shearing machine and rice grass, which is applied in the field of agricultural machinery, can solve the problems of low labor intensity, low recovery rate of treatment, and inconvenient walking on tidal flats, etc., and achieve the effect of strong adaptability and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

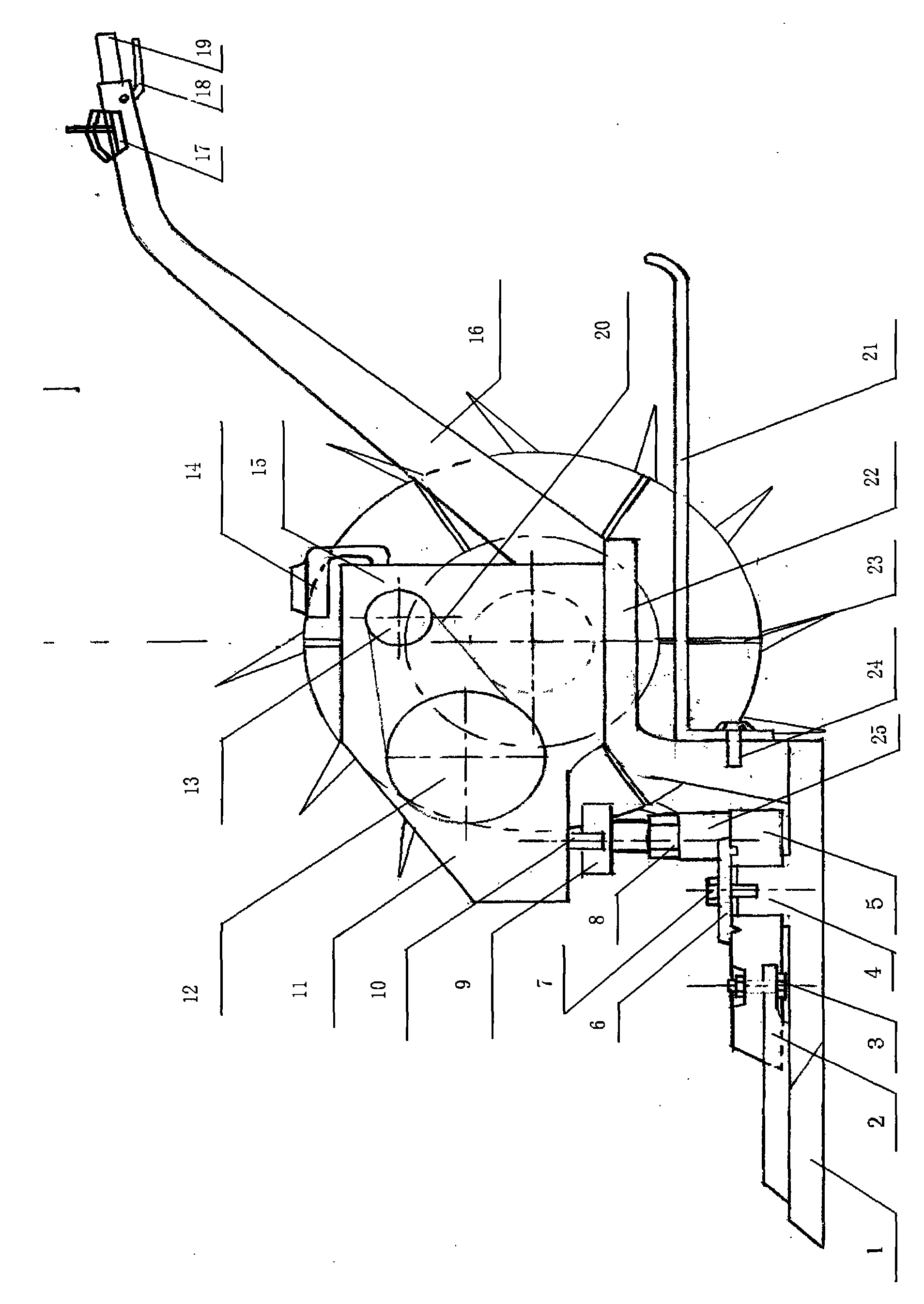

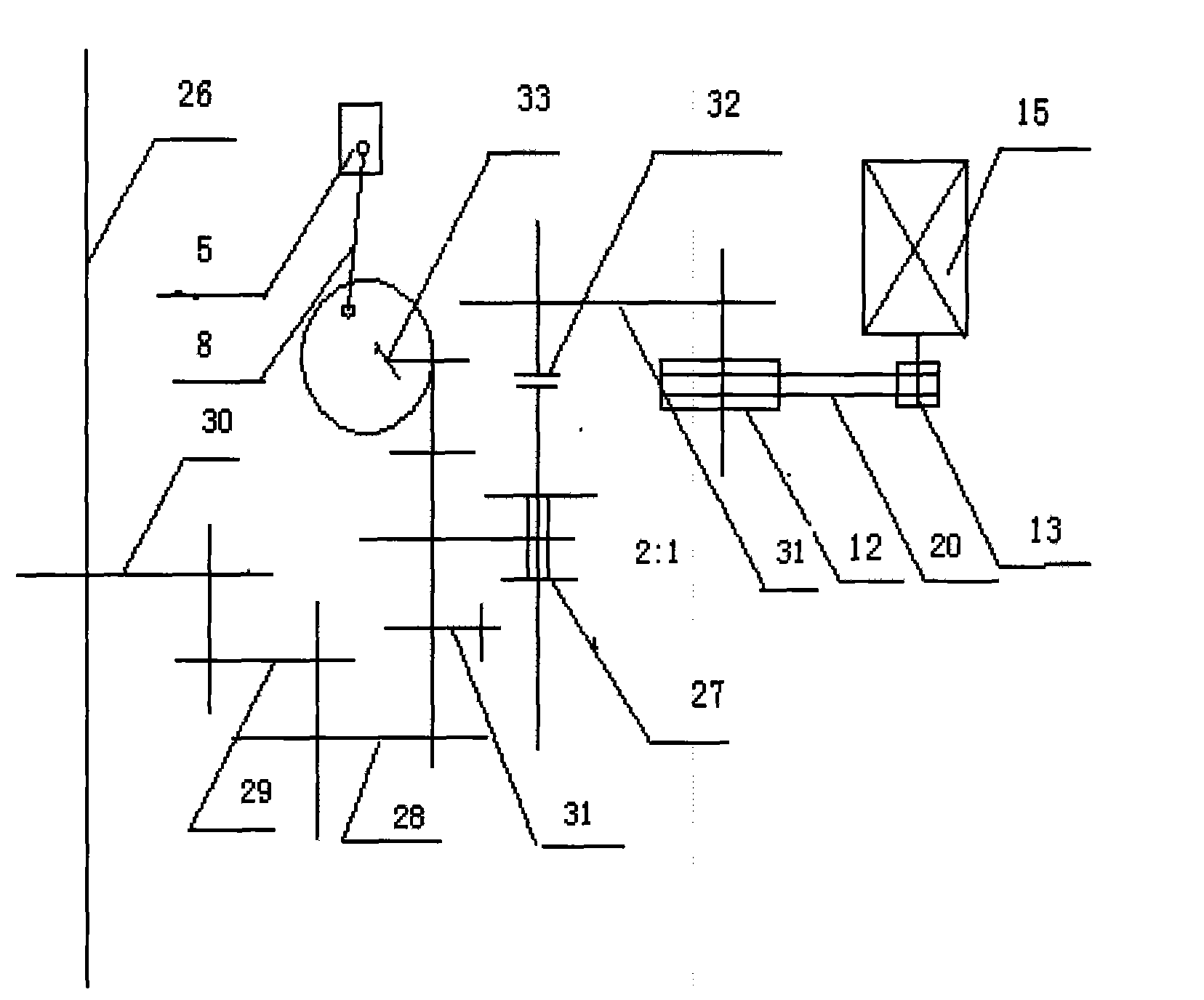

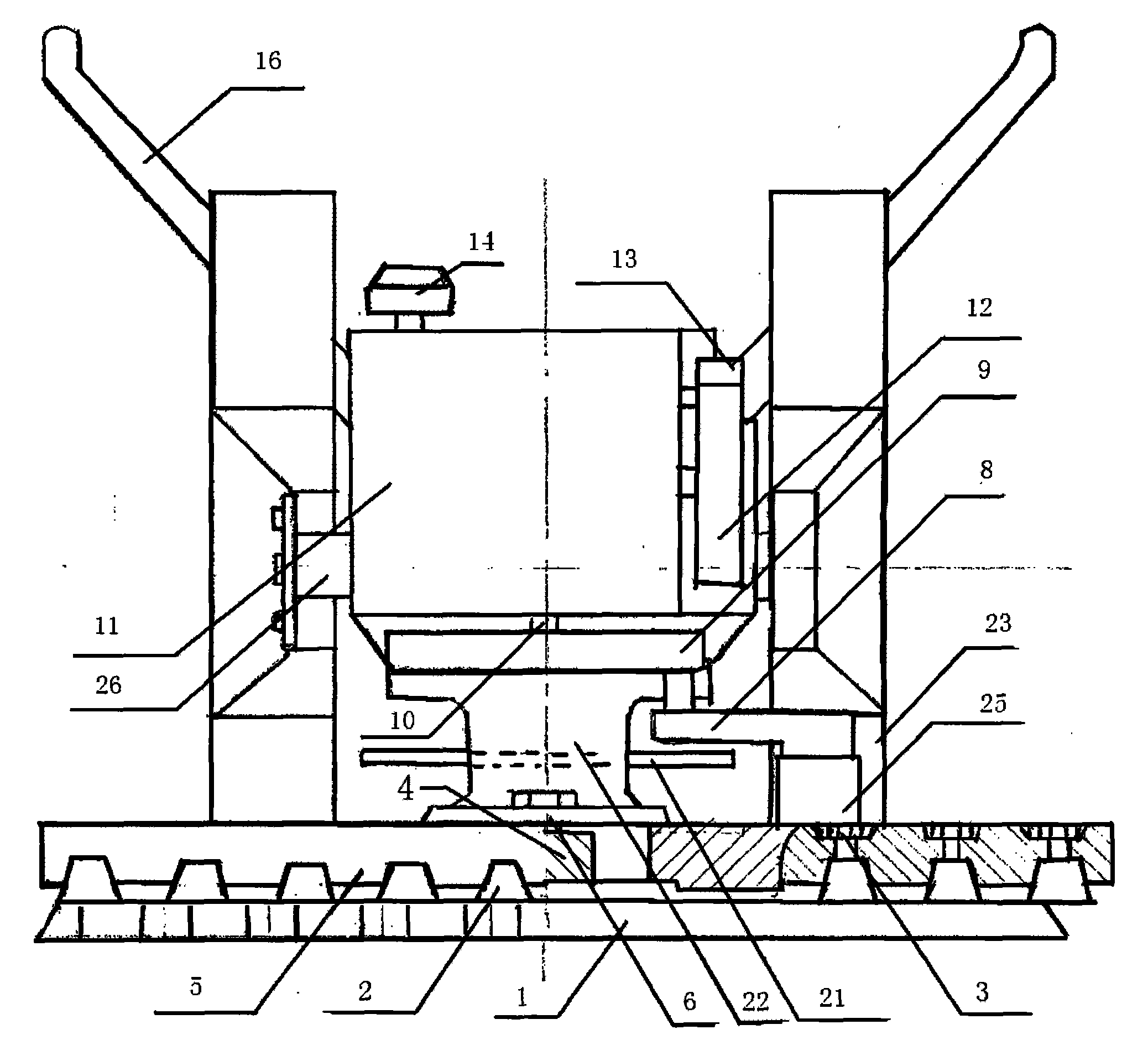

[0032] like Figure 1-6 , manufacture and install each device accessory, promptly become a kind of load-bearing plate formula rice straw mud shearing machine of the present invention.

[0033] The lower tool table (1) is processed from an integral steel plate, and is connected with the frame as a whole through bolts and grooves, and is opened like Figure 4 As shown in the rod entry groove, the front end of the groove is a pointed triangle, which can reduce the resistance under the mud when the whole machine is advancing, and on the other hand can guide the stem of Spartina under the mud to enter the rod entry groove. The limited boss on the lower knife table has a screw hole, and a mud guide slope is also opened after entering the rod groove to further reduce resistance. On the upper knife rest (5) as Figure 4 The processing shown has a knife groove, and the tool is made of spring steel, which has been induction hardened to ensure hardness and toughness at the same time. ...

Embodiment 2

[0040] As embodiment 1, change bearing plate (21) into rubber crawler (34), promptly become a kind of rubber crawler type rice straw mud shearing machine of the present invention.

[0041] Unpowered track is shown in 7,8,9, and this device is made of left and right rubber track (34), bearing frame (35), main load wheel (36), secondary load wheel (37), auxiliary wheel (38) and track The wheel frame (40) is composed of a fixed plate (42) and a load-bearing frame (35) screwed on the Γ-shaped frame. The load-bearing wheel is a hollow cylinder (39) with one end sealed and fixed on the track through a bearing (41). On the wheel frame, the other end is sealed with screws (45) by linoleum (43) and cover plate (44) to prevent silt from entering, and the load-carrying wheel has a mud guide groove, which can discharge the mud on the track to prevent accumulation. There can be a speed difference between the left and right crawlers, effectively reducing the turning moment.

[0042] Its us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com