Production process for pressuring and condensing trichlorosilane synthesized product

A technology for synthesizing products, trichlorosilane, applied in the direction of silicon halide compounds, halosilanes, etc., can solve the problems of extended maintenance period, low condensation efficiency of synthetic products, and large refrigerant consumption, so as to improve condensation efficiency and reduce Refrigerant consumption and the effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Explanation again: the trichlorosilane synthesis product described in the present invention refers to the mixed gas after the synthesis of industrial silicon powder and HCl, and the mixed gas contains H in addition to the dust. 2 , HCl, SiHCl 3 、SiH 2 Cl 2 or SiCl 4 Wait. The trichlorosilane synthesis product referred to herein may also refer to the mixed gas.

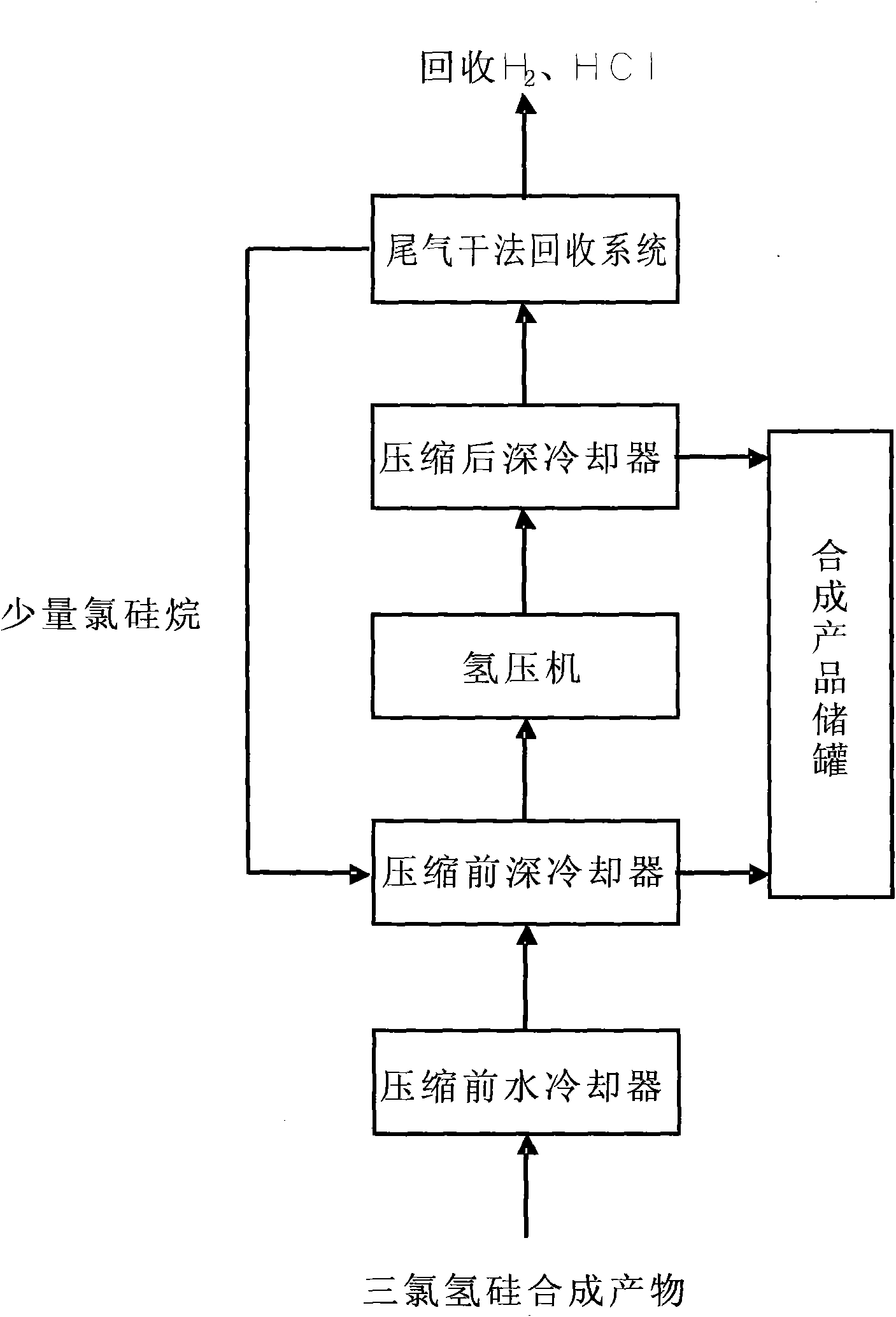

[0025] to combine figure 1 , the production process of the pressurized condensation of the trichlorosilane synthesis product of the present invention is a water cooler before compression, a deep cooler before compression, a hydrogen compressor, a deep cooler after compression, a synthetic product storage tank and a dry tail gas recovery system Implementation, the production process includes five processes of water cooling before compression, cryogenic cooling before compression, pressurization by hydrogen compressor, cryogenic cooling after compression and dry recovery of exhaust gas. The five processes are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com