Method for preparing latex condoms

A condom and dipping technology, applied to male contraceptives, coatings, etc., can solve the problem of no minimum requirements for harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

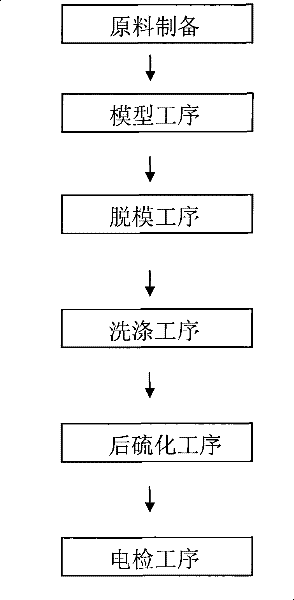

Image

Examples

Embodiment 1

[0039] A method for preparing a condom, comprising the following steps;

[0040] (1) Raw material preparation. Heat the raw material at 35°C for 6 hours, stop the vulcanization when the chloroform value reaches the third to fourth initial stage, and wait for use after dehydration; the components and parts by mass of the raw material are:

[0041] 60% concentrated latex 800 parts

[0042] 10% casein 12 servings

[0043] 10% sodium methylene dinaphthalene sulfonate 4.15 parts

[0044] 50% sulfur 7.9 parts

[0045] 40% zinc N-ethyl N-phenyldithiocarbamate 4.0 parts

[0046]50% zinc diethyldithiocarbamate 1.2 parts

[0047] 50% zinc oxide 3.9 parts,

[0048] 40% thiobis-(3,5)-di-tert-butyl-4-hydroxy 11 parts

[0049] 40% 2,6-di-tert-butyl-4-methylphenol 15 parts

[0050] Potassium hydroxide 1.3 parts

[0051] 140 parts of 25% ammonia solution

[0052] Soft water 30 parts

[0053] The percentages are all percentages by mass.

[0054] (2) Model process. After the condom...

Embodiment 2

[0063] A method for preparing a condom, comprising the following steps;

[0064] (1) Raw material preparation. Heat the raw material at 35°C for 6 hours, stop the vulcanization when the chloroform value reaches the third to fourth initial stage, and wait for use after dehydration; the components and parts by mass of the raw material are:

[0065] 60% concentrated latex 800 parts

[0066] 10% casein 12 servings

[0067] 10% sodium methylene dinaphthalene sulfonate 4.15 parts

[0068] 50% sulfur 7.9 parts

[0069] 40% zinc N-ethyl N-phenyldithiocarbamate 4.0 parts

[0070] 50% zinc diethyldithiocarbamate 1.2 parts

[0071] 50% zinc oxide 3.9 parts,

[0072] 40% thiobis-(3,5)-di-tert-butyl-4-hydroxy 11 parts

[0073] 40% 2,6-di-tert-butyl-4-methylphenol 15 parts

[0074] Potassium hydroxide 1.3 parts

[0075] 140 parts of 25% ammonia solution

[0076] Soft water 30 parts

[0077] The percentages are all percentages by mass.

[0078] (2) Model process. After the condo...

Embodiment 3

[0085] A method for preparing a condom, comprising the following steps;

[0086] (1) Raw material preparation. Heat the raw material at 35°C for 6 hours, stop the vulcanization when the chloroform value reaches the third to fourth initial stage, and wait for use after dehydration; the components and parts by mass of the raw material are:

[0087] 60% concentrated latex 800 parts

[0088] 10% casein 12 servings

[0089] 10% sodium methylene dinaphthalene sulfonate 4.15 parts

[0090] 50% sulfur 7.9 parts

[0091] 40% zinc N-ethyl N-phenyldithiocarbamate 4.0 parts

[0092] 50% zinc diethyldithiocarbamate 1.2 parts

[0093] 50% zinc oxide 3.9 parts,

[0094] 40% thiobis-(3,5)-di-tert-butyl-4-hydroxy 11 parts

[0095] 40% 2,6-di-tert-butyl-4-methylphenol 15 parts

[0096] Potassium hydroxide 1.3 parts

[0097] 140 parts of 25% ammonia solution

[0098] Soft water 30 parts

[0099] Said percentages are mass percentages;

[0100] (2) Model process. After the condom mode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com