Continuous and variable gas distribution control system of spark ignition engine

A control system and engine technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems that the exhaust valve timing and opening and closing angle control cannot be controlled arbitrarily, and the engine speed and load cannot be controlled. , to achieve the effect of improving inflation efficiency, simple structure and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

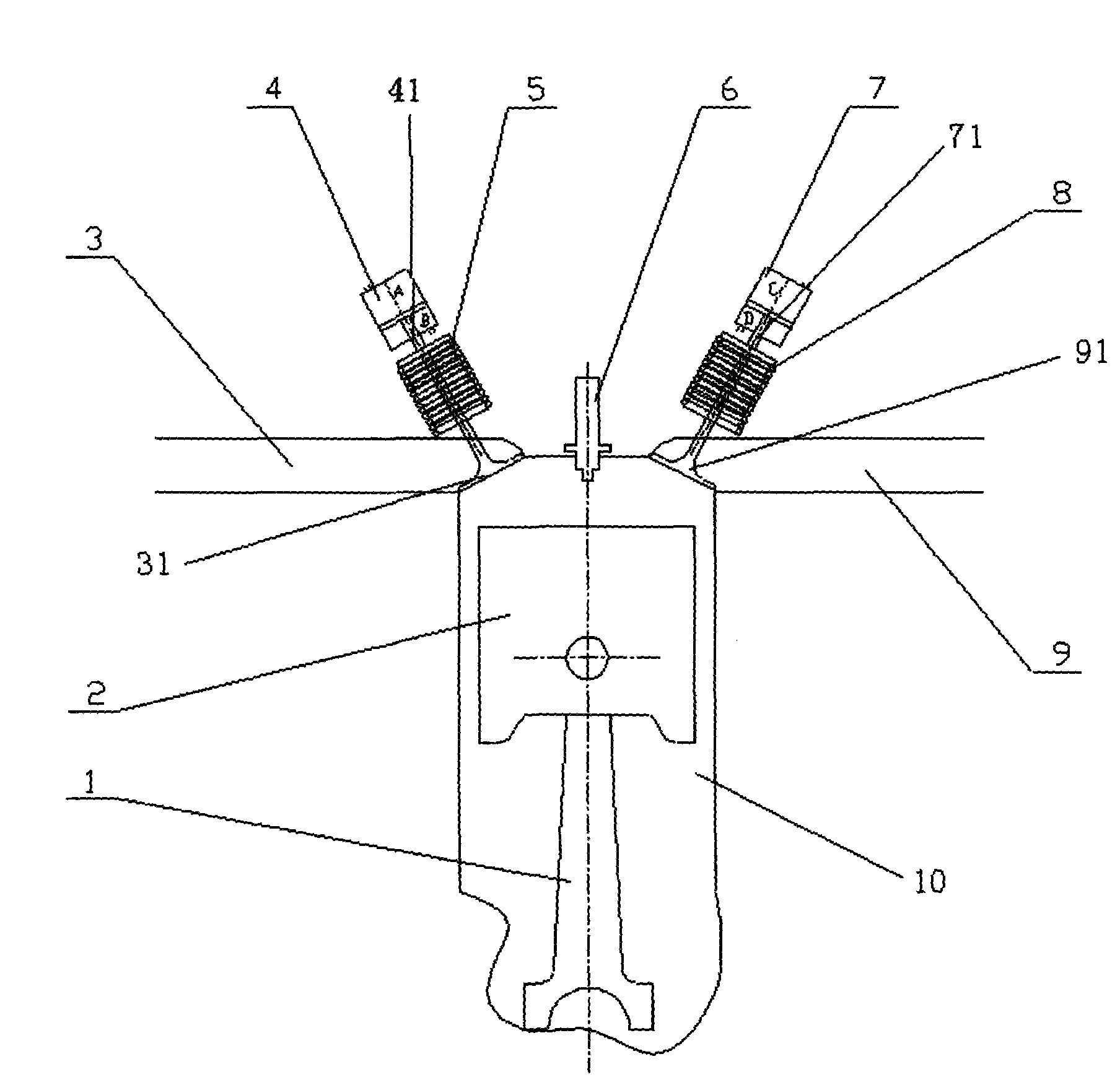

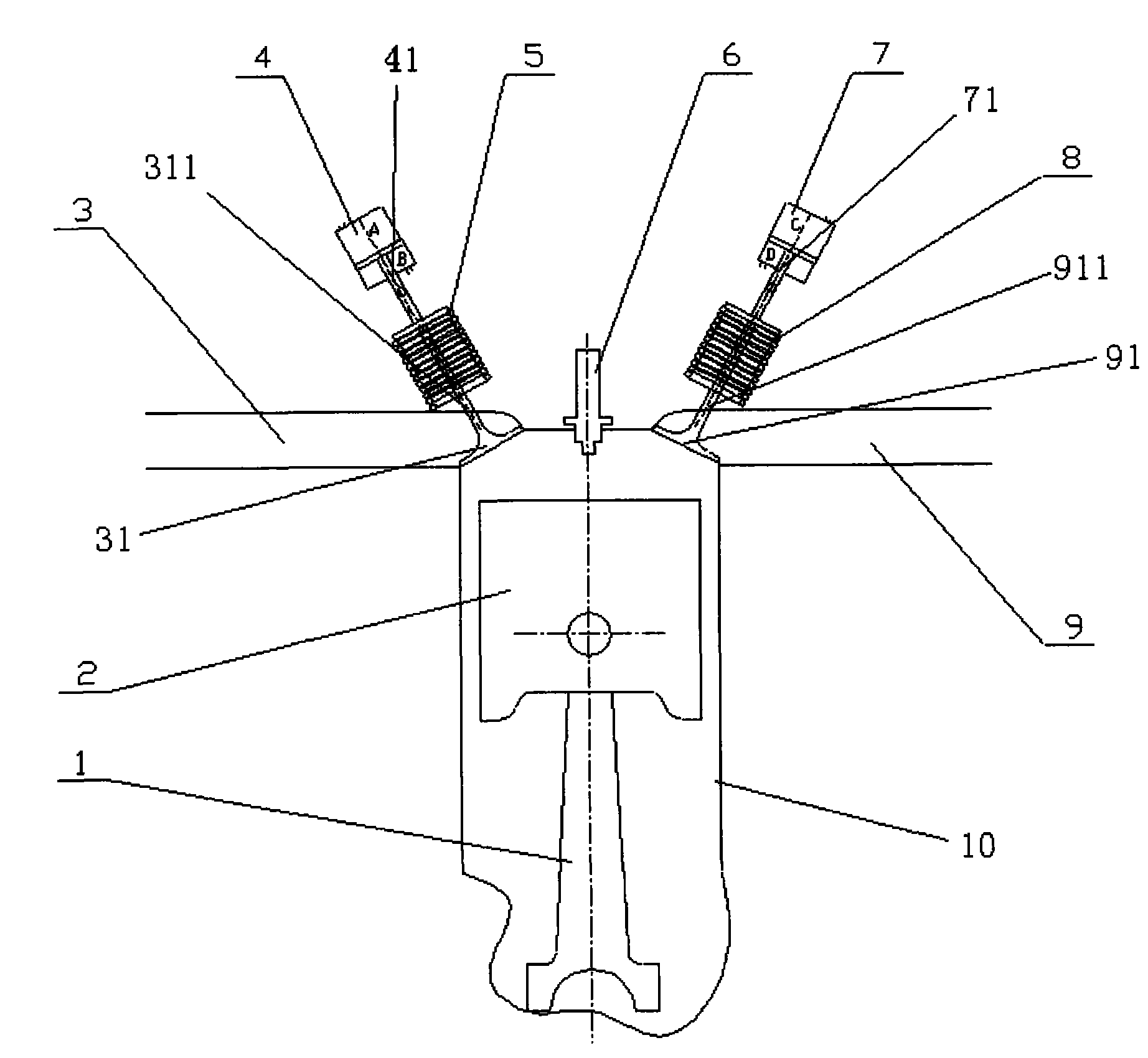

[0015] A continuously variable gas distribution control system for an ignition engine according to the present invention, see figure 1 , including crank linkage mechanism 1, piston 2, intake manifold 3, intake valve spring 5, spark plug 6, exhaust valve spring 8, exhaust pipe 9 and engine block 10, crank linkage mechanism 1 and piston 2 Connected, and the piston 2 is arranged in the engine block 10, and the intake manifold 3 and the exhaust pipe 9 communicate with the engine block 10. An intake valve 31 is provided at the joint between the intake manifold 3 and the engine block 10, and the intake valve 31 is connected to the hydraulic piston push rod 41 of the intake hydraulic control assembly 4 through the intake valve spring 5. At this time, the The intake valve stem of the ignition internal combustion engine acts as a push rod for the hydraulic piston. An exhaust valve 91 is provided at the connection between the exhaust pipe 9 and the engine block 10, and the exhaust valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com