Bridgewire welding device for novel digital electronic detonator

A technology of digital electronic detonator and welding device, which is applied in welding equipment, non-electric welding equipment, welding/welding/cutting items, etc., can solve the problems of limited use range of ordinary detonators, gunpowder explosion, etc. The effect of increasing the contact area and reducing the process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

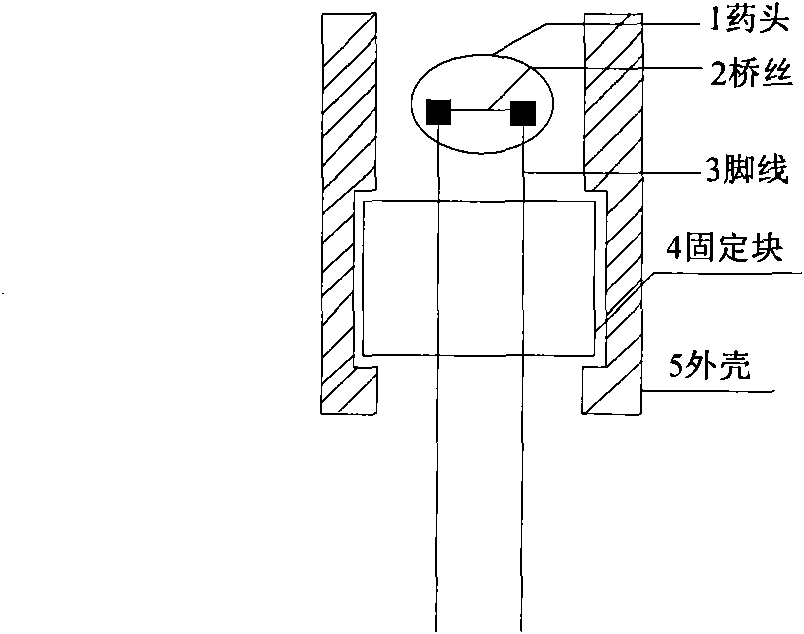

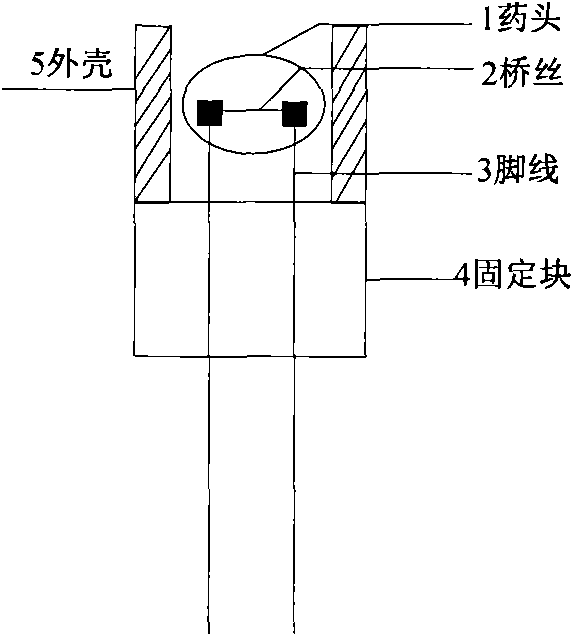

[0017] like figure 1 As shown, the bridge wire welding device for a digital detonator consists of two metal foot wires 3, a drug head 1, a fixed block 4 and a shell 5; the drug head includes a bridge wire 2 and a gunpowder 1 coated on the bridge wire; the two A metal leg wire 3 is located in the shell 5 and extends to the outside of the shell 5, one end of the two metal leg wires 3 located in the shell 5 is used for welding the bridge wire 2, and the two metal leg wires 3 are used for welding the bridge wire 2. The foot wire 3 extends to one end outside the shell 5 for connecting the ignition circuit of the digital electronic detonator; the two ends of the two metal foot wires 2 are sheet-shaped; the fixed block 4 is located in the shell 5 for The two metal feet 3 are fixed; the shape of the fixing block 4 is a cube with rounded corn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com