Method for purifying high-purity phenyl ethyl malonate

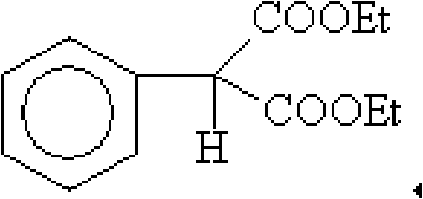

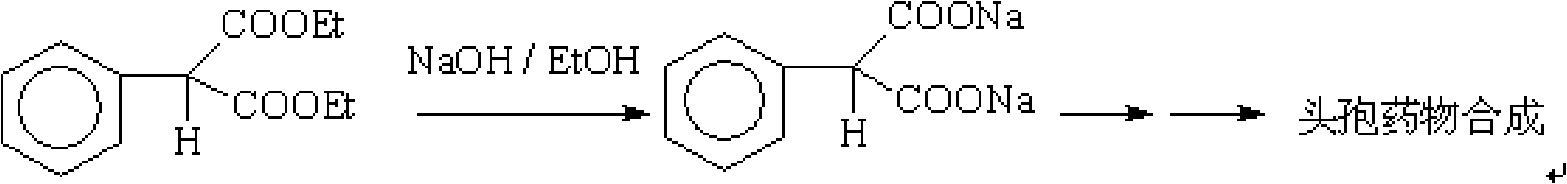

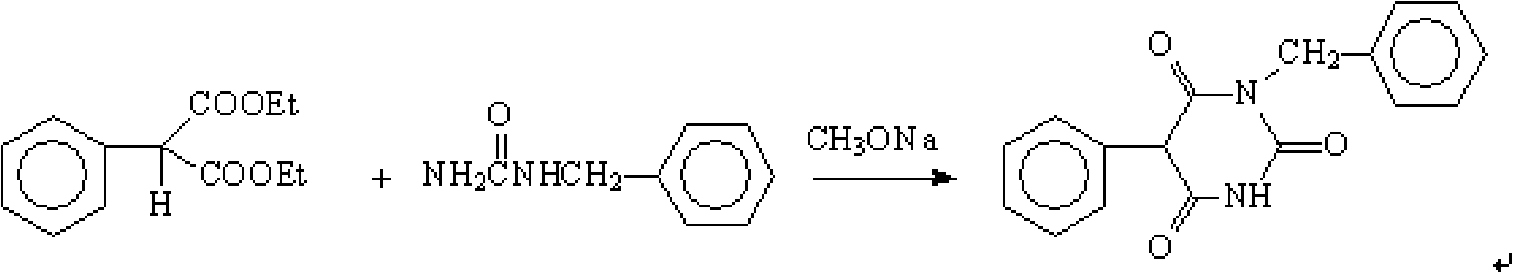

A technology of diethyl phenylmalonate and ethyl acetate is applied in the field of purification of high-purity diethyl phenylmalonate, which can solve the problems of difficulty in separation, affecting the quality of downstream drug production, and being difficult to remove.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] In the four-necked flask of 250ml, add phenylmalonate 80g (93.5%) impurity (III) content 0.51%, normal hexane 144.0g[phenylmalonate: normal hexane=1: 1.8 ( w / w)], activated carbon 4g, warming up to 30°C. After filtration, the filtrate was cooled to -10~-5°C, a large amount of white solids were precipitated, stirred for 45 minutes, and 77 g of crude product was obtained by filtration. The solvent was distilled off under reduced pressure at 60°C / 0.8 MPa to obtain 71.6 g of a colorless transparent liquid with a purity of 97.3%, impurity (III) content of 0.092%, and residual solvent of less than 0.1%. Yield 93.1%.

[0042] Add phenylmalonate 70g (97.3%) impurity (III) content 0.092% in the four-necked beaker of 250ml, normal hexane 126.0g[phenylmalonate: normal hexane=1: 1.8 ( w / w)], warming up to 30°C and stirring for 30 minutes. After cooling to -10°C to -5°C, a large amount of white solids precipitated, stirred for 30 minutes, and filtered to obtain 74g of crude produ...

Embodiment 2

[0044] In a 250ml four-necked flask, add 80g (94.1%) of diethyl phenylmalonate (94.1%) with an impurity (III) content of 0.45%, add petroleum ether (60-90°C) 128.0g [diethyl phenylmalonate : petroleum ether=1:1.6 (w / w)], activated carbon 4g. Raise the temperature to 30°C and stir for 30 minutes. filter. The filtrate was cooled to -10~-5°C, a large amount of white solid crystallized, stirred for 45 minutes, filtered, and 90.1 g of wet product was obtained. The solvent was distilled off under reduced pressure at 70°C / 0.6 MPa to obtain 72.5 g of a colorless transparent liquid with a purity of 97.7%, impurity (III) content of 0.075%, and residual solvent of less than 0.1%. Yield 94.1%.

[0045] In the four-necked flask of 250ml, add diethyl phenylmalonate 70g (97.7%), impurity (III) content 0.075%, sherwood oil 128g[diethyl phenylmalonate: sherwood oil=1: 1.6 ( w / w)], warming up to 30°C and stirring for 30 minutes. After cooling to -8°C to -5°C, a large amount of white solids...

Embodiment 3

[0047]Add 100g diethyl phenylmalonate (92.8%) in the 500ml four-necked flask, impurity (III) content 0.52%, add sherwood oil 160g, 8g ethyl acetate [diethyl phenylmalonate: solvent= 1:1.68 (w / w)], activated carbon 5g, stirred, mixed evenly, filtered. The filtrate was cooled to -10~-5°C, stirred for 45 minutes, and filtered to obtain 98g of wet product. The solvent was recovered under reduced pressure at 75°C / 0.5 MPa to obtain 88 g of a colorless transparent liquid with a purity of 98.6%, impurity (III) content of 0.062%, and residual solvent of 0.08%. Yield 93.5%.

[0048] Add 80g (98.6%) of diethyl phenylmalonate in a 500ml four-necked beaker, impurity (III) content of 0.062%, petroleum ether 128g, 6.4g ethyl acetate [diethyl phenylmalonate: mixed Solvent=1:1.68 (w / w)], heated up to 30°C, and stirred for 30 minutes. After cooling to -8°C to -5°C, a large amount of white solids precipitated, stirred for 30 minutes, and filtered to obtain 79g of crude product. The solvent w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com