Method for preparing cycloamylose 4-alpha-glycosyl transferase production

A technology of glycosyltransferase and macrocyclodextrin, which is applied in the field of enzyme engineering, can solve the problems of few research results on enzymes producing macrocyclodextrin, achieve huge potential commercial value, high heat resistance, and easy separation and purification steps line effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、4

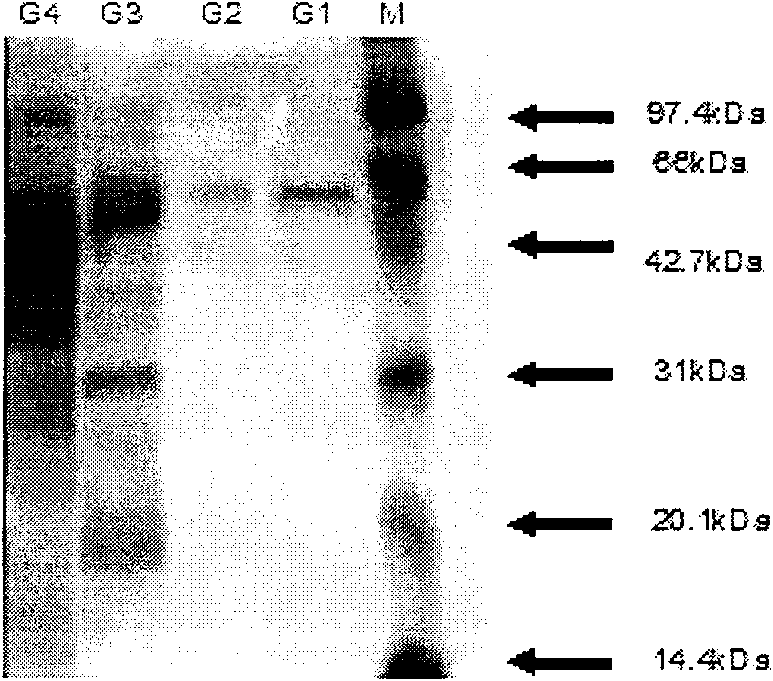

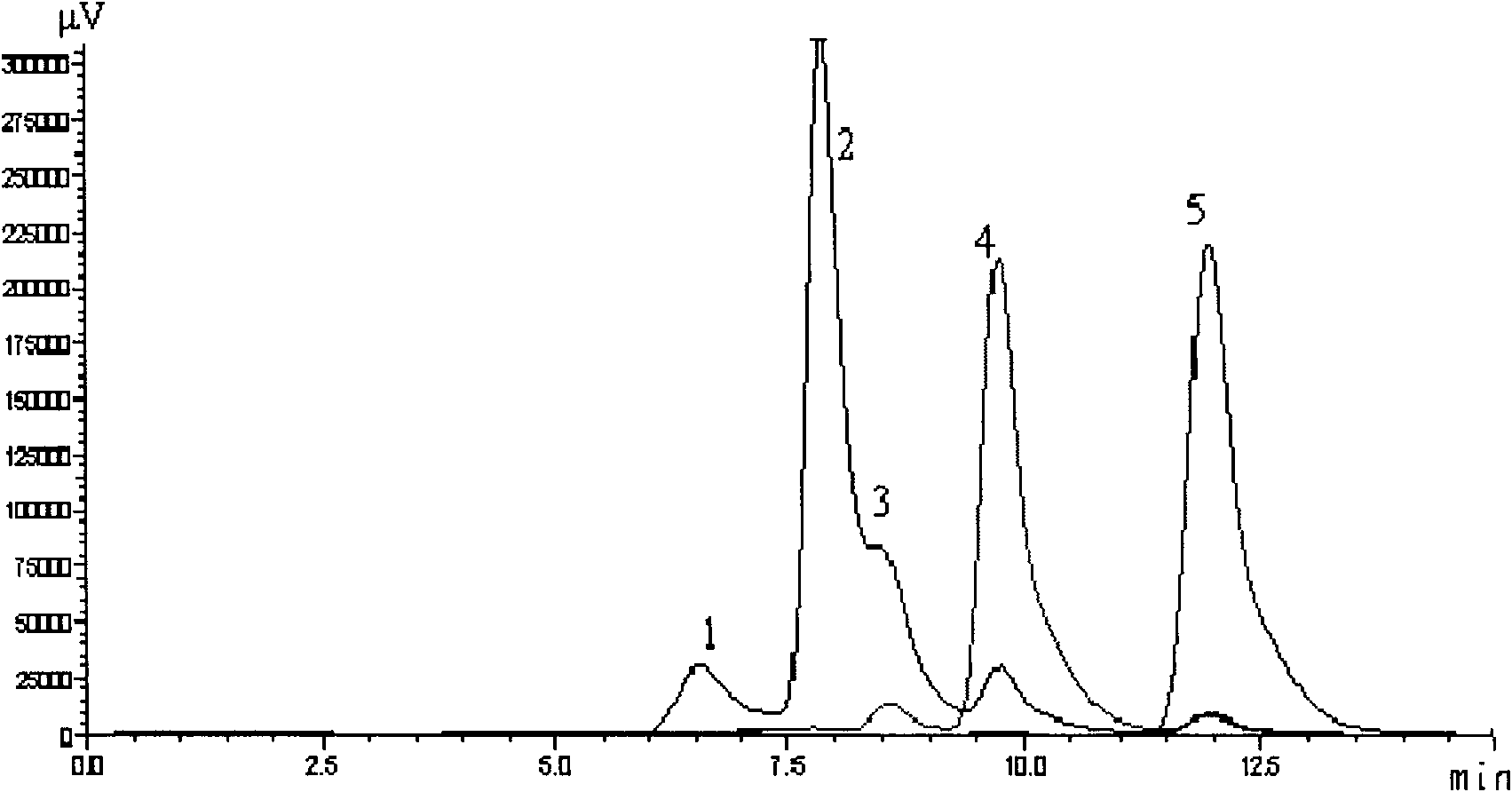

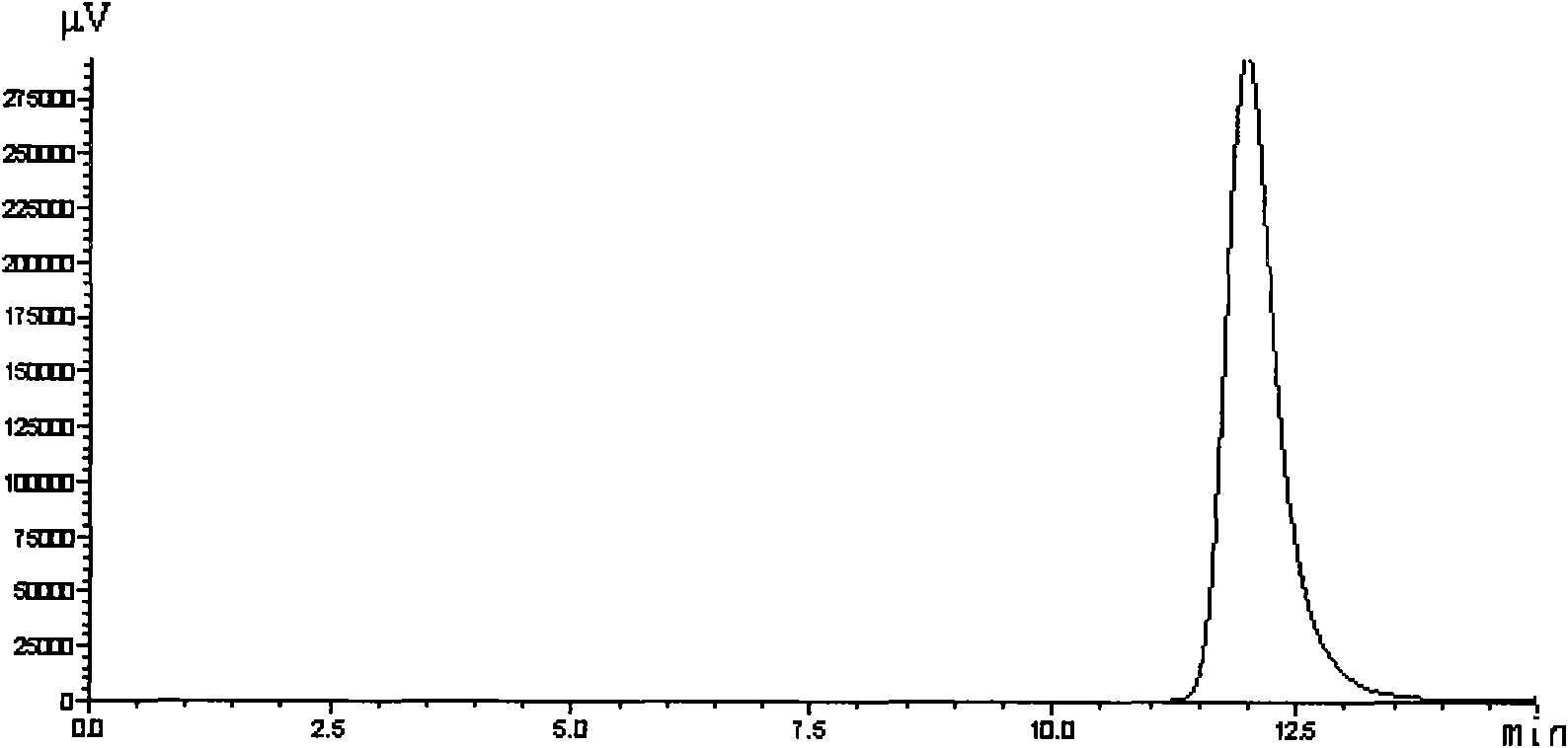

[0023] Preparation and purification of embodiment 1, 4-alpha-glycosyltransferase

[0024] 1. Enzyme preparation

[0025] 1) Single colony selection: Dip a small amount of bacterial solution from the genetically engineered strains with an inoculation loop to draw an LB plate containing 100 μg / mL ampicillin sodium, and place the plate in a biochemical incubator at 37°C for 12 hours at a constant temperature;

[0026] 2) Seed culture: Pick a single colony and inoculate it in a 50 mL conical flask containing 100 μg / mL ampicillin sodium LB medium, fix the conical flask on a constant temperature shaker at 37°C, 200 rpm, and vibrate for 8 hours to make seeds Culture medium;

[0027] 3) Fermentation culture: Inoculate the seed medium into a fermenter of 3L medium containing ampicillin sodium 100 μg / mL, adjust the temperature to 37°C, stir at 200 rpm, pH to 7.5, and ventilation to 10L / h , the inoculum size was 10%, adding 10mL / L soybean oil as an antifoaming agent, and fermented and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com