Method for producing working solution for virus hemagglutination inhibition tests and device applied thereby

A technology of hemagglutination inhibition test and inhibition test, which is applied in the field of hemagglutination inhibition test working solution, can solve the problems of unsuitable field application, long reaction time, complicated methods, etc., and achieve the effects of short reaction time, convenient handling and portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The preparation of hemagglutination inhibition test working solution of the present invention: 200g sodium citrate is added in 1000mL water, after water bath dissolves, then add glucose 500g, sodium chloride (NaCl) 170g, chromium chloride (CrCl) 3 ·6H 2 O) 2g, sodium azide (NaN 3 ) 10g, adjust the pH to 7.0 with NaOH.

[0045] Make a 20-fold dilution when used.

Embodiment 2

[0047] The preparation of hemagglutination inhibition test working solution of the present invention: 200g sodium citrate is added in 1000mL water, after water bath dissolves, then add glucose 500g, sodium chloride (NaCl) 160g, potassium dihydrogen phosphate (KH 2 PO 4 ) 4g, disodium hydrogen phosphate (Na 2 HPO 4 12H 2 O) 58g, potassium chloride (KCl) 4g, chromium chloride (CrCl 3 ·6H 2 O) 2g, sodium azide (NaN 3 ) 10g, adjust the pH to 7.0 with NaOH.

[0048] Make a 20-fold dilution when used.

Embodiment 3

[0050] Preparation of hemagglutination inhibition test working solution of the present invention: 200g sodium citrate is added in 1000mL water, after water bath dissolves, then add glucose 500g, sodium chloride (NaCl) 170g, potassium dihydrogen phosphate (KH 2 PO 4 ) 13.6g, chromium chloride (CrCl 3 ·6H 2 O) 2g, sodium azide (NaN 3 ) 10g, adjust the pH to 7.0 with NaOH.

[0051] Make a 20-fold dilution when used.

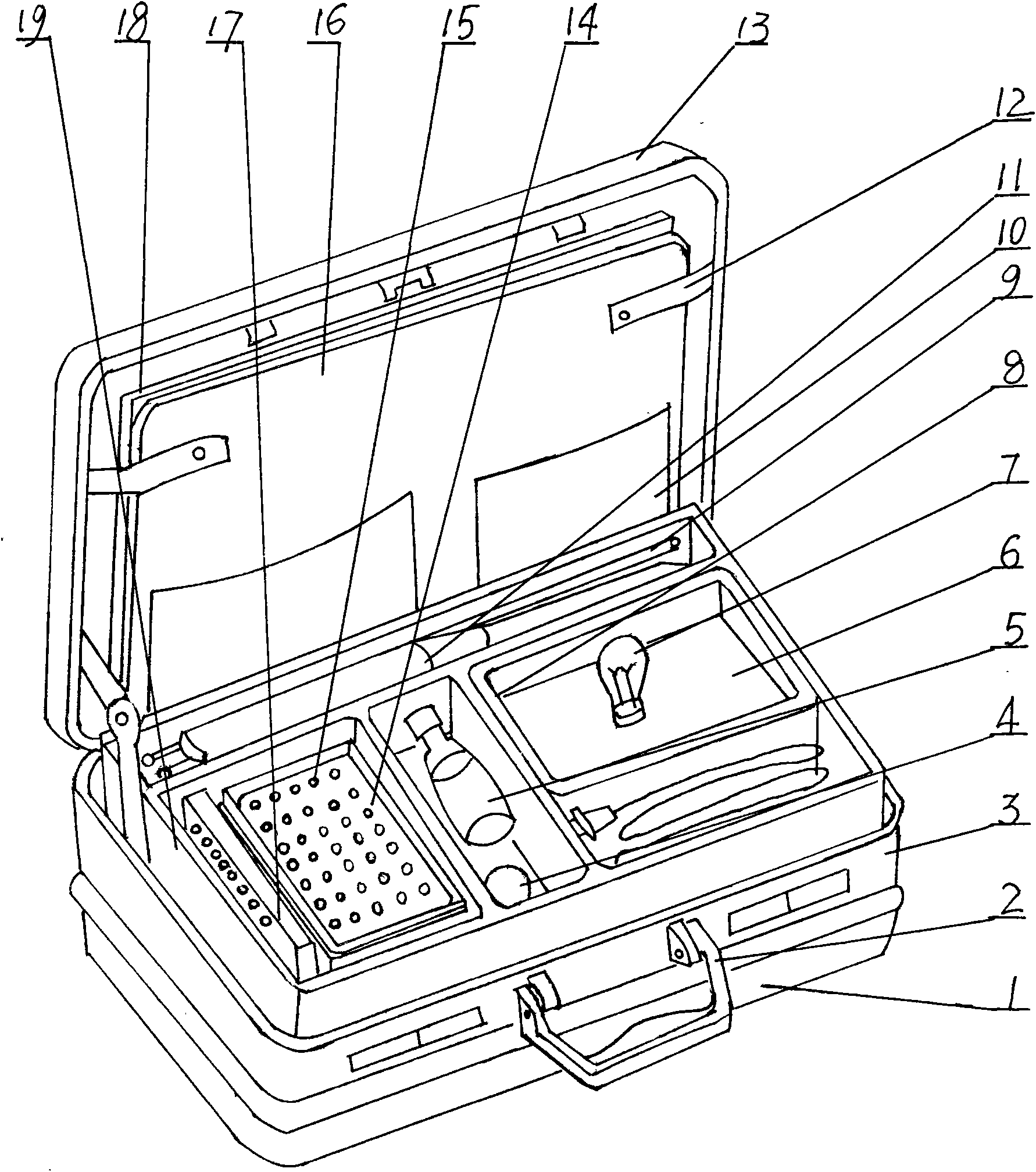

[0052]An application device for a virus hemagglutination inhibition test working fluid, comprising a box body 1, the box body 1 is composed of a box cover 13, a box bottom 3 with a handle 2, and a plate glass 18 is arranged in the baffle plate 16 of the box cover 13; The bottom of the box 3 is provided with a detection tool box 19, and the detection tool box 19 is provided with a partition 8, and the partition 8 is provided with a medicine bottle 5, a micro pipette 11, a blood coagulation reaction plate 17, a centrifuge tube 15, a centrifuge tube rack 14, Sucti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com