Secondary fermentation process, formula and tunnel-type fermentation chamber of mushroom compost

A technology of secondary fermentation and culturing material, which is applied in the preparation of organic fertilizers, organic fertilizers, and bio-organic part treatment, etc. Revenue, effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

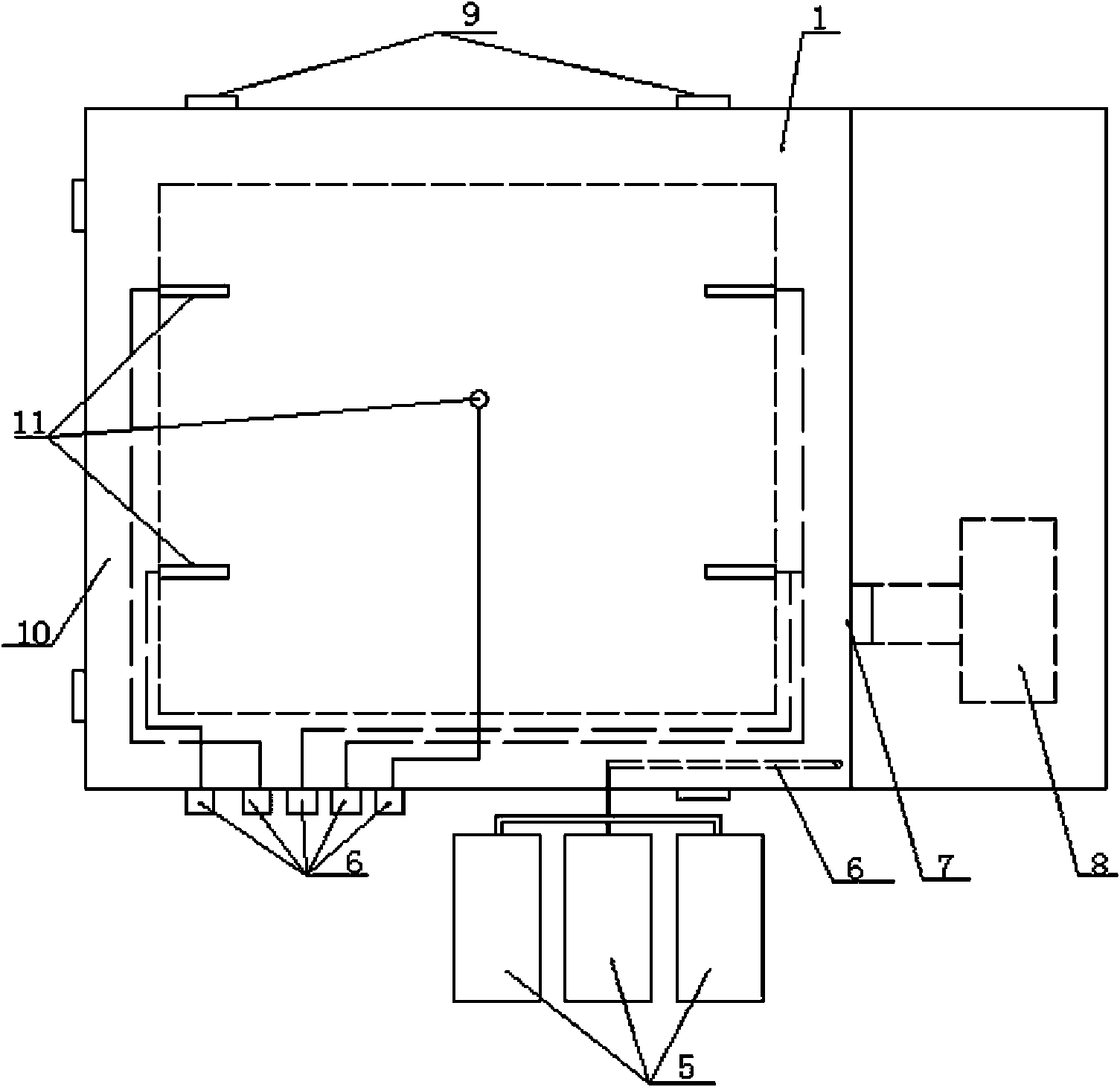

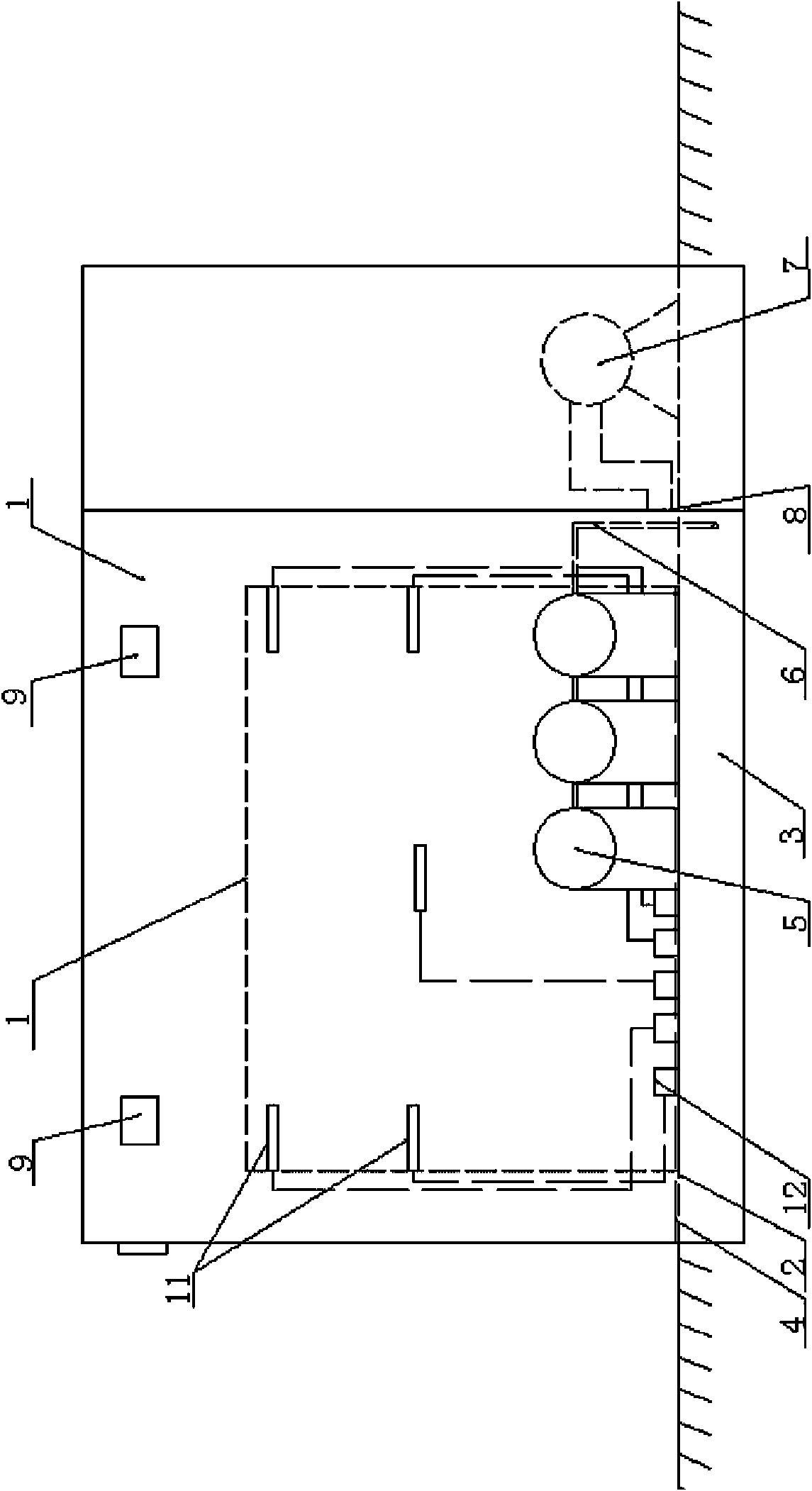

Method used

Image

Examples

Embodiment 1

[0026] (1) The formula of culture material:

[0027] 4000 parts of dry grass, 2000 parts of dry cow dung, 11000-12000 parts of water, 30 parts of compound fertilizer (including nitrogen, phosphorus and potassium), 30 parts of urea, 30 parts of potassium chloride, 80 parts of superphosphate, gypsum powder 100 parts, 100 parts ash powder, 50 parts cake; the cake material is rapeseed cake or peanut cake.

[0028] Potassium chloride in it is good for moisture absorption, which makes the fiber in the forage easy to resist moisture and soften, which is good for the growth of mushroom fruiting bodies and improves the quality of mushrooms.

[0029] (2) process of the present invention:

[0030] 1. Primary fermentation:

[0031] (1) Pre-stacking and pre-wetting: After accurately weighing the fresh non-mildew forage, cow dung and other ingredients, first cut the forage and put it in 0.5-2% (1% is the best) lime water Soak (how long?) Fully pre-wet, pick up and pile up and step on it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com