Low-plasticity scandium-aluminum alloy piston material proportioning and smelting technology

A technology of scandium aluminum alloy and low plasticity, which is applied in the proportioning and smelting process of making aluminum alloy piston materials, which can solve the problems of insufficient wear resistance and poor heat resistance, and achieve the effect of improving the tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

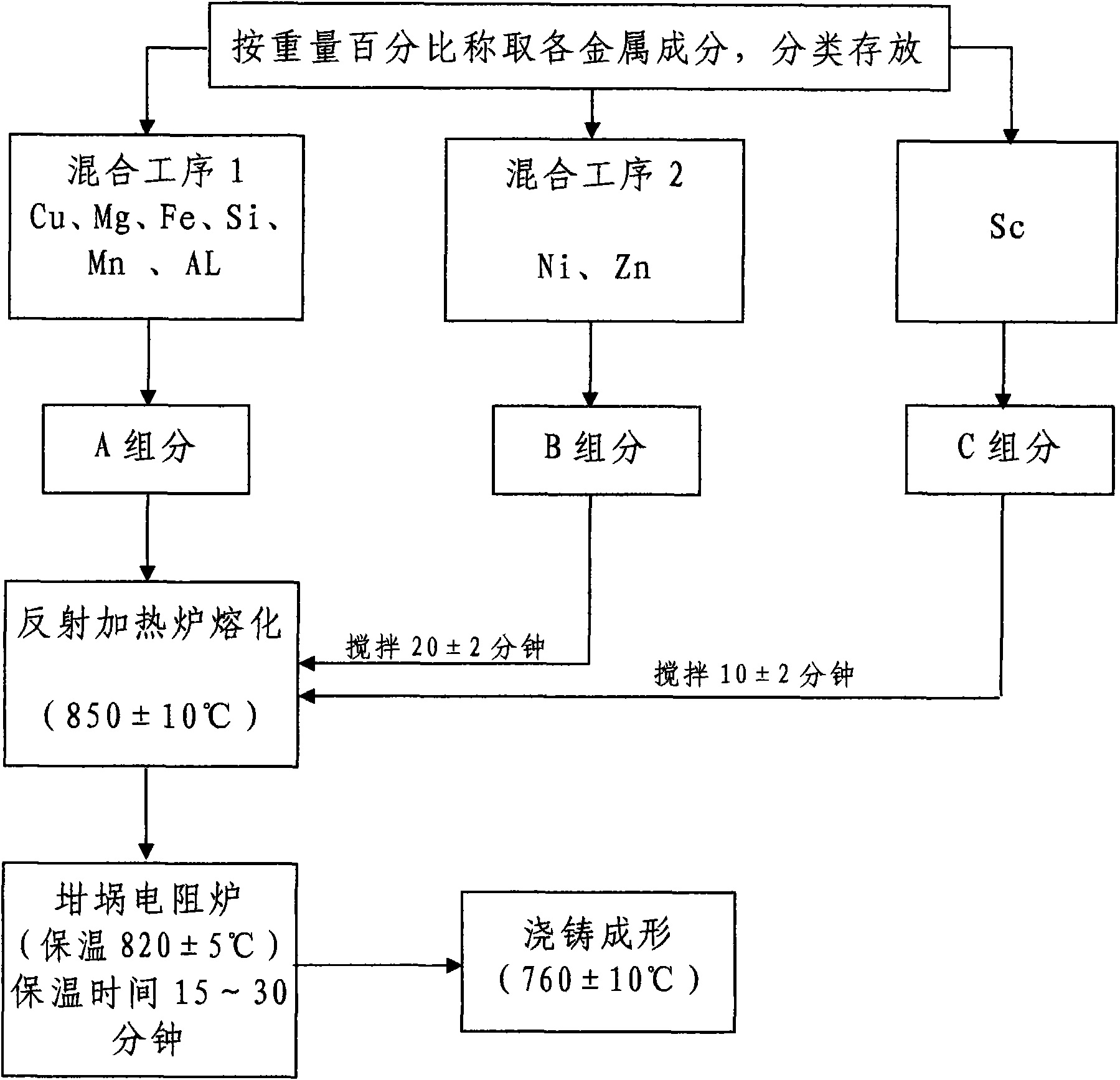

[0024] 1000kg of charge is prepared according to the ratio of low-plasticity scandium-aluminum alloy piston materials, and the ratio is percentage by weight. Take 1kgMg, 15kgCu, 95kgSi, 3kgFe, 2kgMn, 1kgNi, 1kgZn and 0.5kgSc respectively, and take 881.5kgAL. Then mix Cu, Mg, Fe, Si, Mn, and Al and store them separately as component A. Then mix Ni and Zn and store them separately as component B. Store Sc separately as component C. When smelting, first put component A into the reverberatory furnace to melt, the furnace temperature is 845±5°C, then put component B into the solution of component A, stir for 18 minutes, then put component C into component A+B solution, stirring was continued for 8 minutes. Finally, transfer the scandium-aluminum alloy solution into a crucible resistance furnace for heat preservation at 820±5°C for 15 minutes.

Embodiment 2

[0026] According to the ratio of low-plasticity scandium-aluminum alloy piston material, 1000kg of charge is prepared, and the ratio is percentage by weight. Take 2kgMg, 25kgCu, 97.5kgSi, 5.5kgFe, 3kgMn, 2kgNi, 2kgZn and 0.75kgSc respectively, and take 862.25kgAL. The grouping mixing is the same as in Example 1 and stored separately. When smelting, first put component A into the reverberatory furnace to melt, the furnace temperature is 850±5°C, then put component B into the solution of component A, stir for 20 minutes, then put component C into component A+B solution, stirring was continued for 10 minutes. Finally, transfer the scandium-aluminum alloy solution into a crucible resistance furnace for heat preservation at 820±5°C, and the heat preservation time is 22 minutes.

Embodiment 3

[0028] According to the ratio of low-plasticity scandium-aluminum alloy piston material, 1000kg of charge is prepared, and the ratio is percentage by weight. Take 3kgMg, 35kgCu, 100kgSi, 8kgFe, 4kgMn, 3kgNi, 3kgZn and 1kgSc respectively, and take 843kgAL. The grouping mixing is the same as in Example 1 and stored separately. When smelting, first put component A into the reverberatory furnace to melt, the furnace temperature is 855±5°C, then put component B into the solution of component A, stir for 22 minutes, then put component C into component A+B solution, stirring was continued for 12 minutes. Finally, transfer the scandium-aluminum alloy solution into a crucible resistance furnace for 820±5°C heat preservation, and the heat preservation time is 30 minutes.

[0029] It is verified by the above three examples that, within the proportioning range, as the content of Sc increases, its performance also increases synchronously. Because Sc is expensive, the amount of Sc should ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com