High-iron hypereutectic aluminum-silicon alloy and preparation method thereof

An aluminum-silicon alloy and hypereutectic technology, applied in the field of aluminum-silicon alloy materials, can solve the problems of excessive iron content, high aluminum alloy recycling cost, and difficult recycling, and achieve improved tensile strength, good alloy material uniformity, The effect of improving the properties of the alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

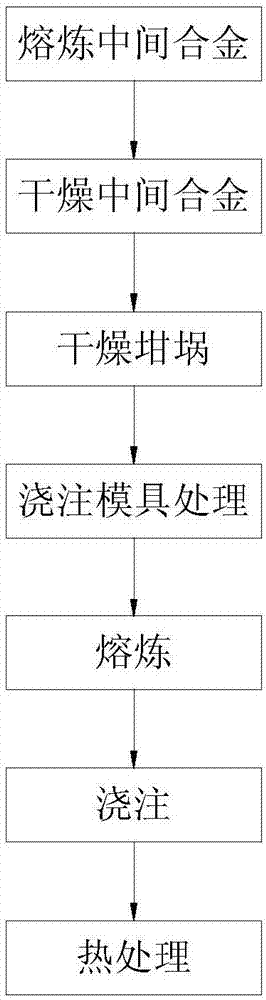

[0025] The invention provides a high-iron hypereutectic aluminum-silicon alloy, the mechanical properties of which can be close to or even better than those of aluminum-silicon alloys without iron or with low iron content. like figure 1 Shown, the present invention prepares the process of high-iron hypereutectic aluminum-silicon alloy as follows:

[0026] (1) Melting master alloy: master alloy is prepared by ZGJL-0.025-50-2.5 intermediate frequency vacuum induction melting furnace. Respectively cast master alloys with Al-30wt.% Si, Al-10wt.% Mn, Al-20wt.% Fe, Al-4.5wt.% P, Al-50wt.% Cu, Al-35wt.% Mg, The purpose of using a vacuum melting furnace for the master alloy is to prevent the high-temperature alloy elements from being oxidized and to ensure the accuracy of the addition of each element in the alloy.

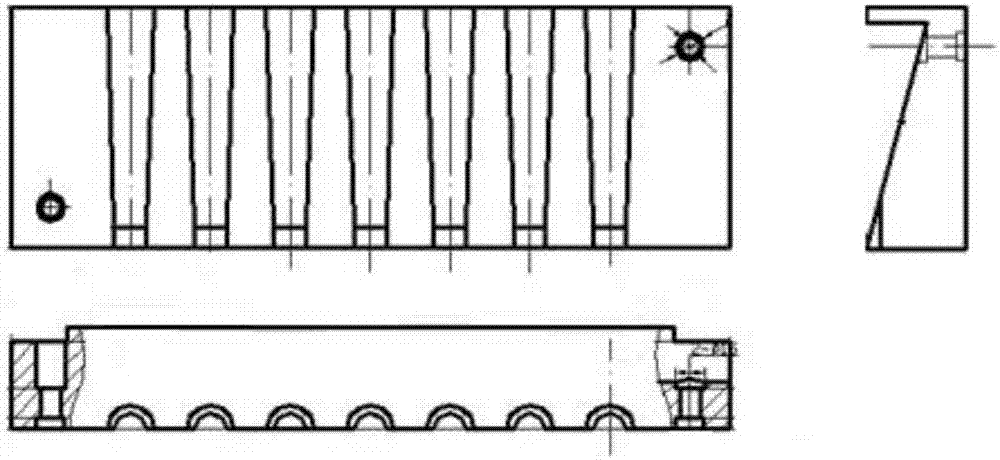

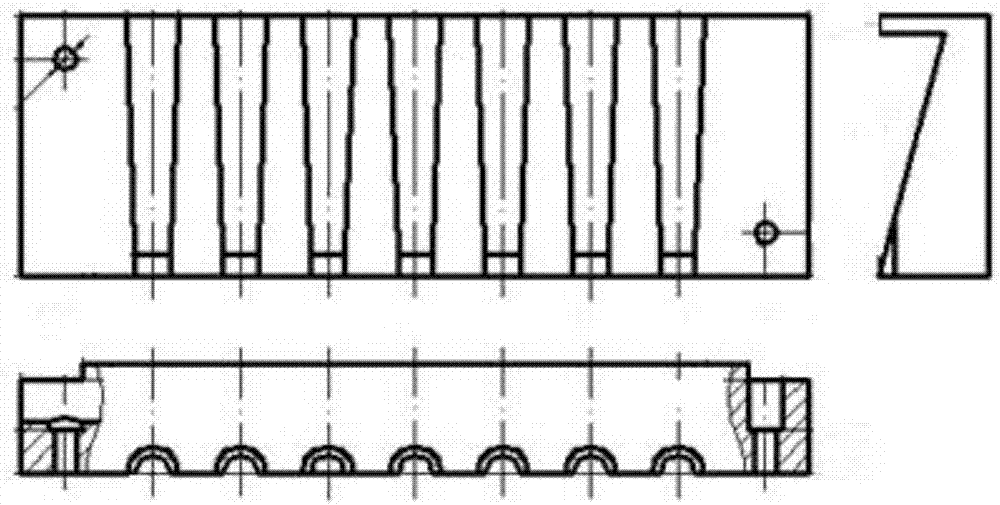

[0027] (2) Alloy smelting: SG-5-12 resistance electric furnace is used to smelt the alloy, the purpose is to make the sample smelting environment closer to the productio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com