Aluminum alloy honeycomb panel and production method thereof

A production method and aluminum alloy technology, applied in the direction of metal layered products, chemical instruments and methods, layered products, etc., can solve the problems of reducing the strength and weight of aluminum alloy honeycomb panels to a limited extent, and achieve high fire resistance and Tensile strength improvement, the effect of improving the tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0065] 300 mg of graphene oxide (purity: 98%, sheet diameter: 20 μm, sheet thickness: 4 nm) was dissolved in water and ultrasonically dispersed to obtain a 5 mg / ml graphene oxide aqueous solution.

[0066] Dissolve 3 mg of sodium tetraborate and 150 mg of sodium dodecyl sulfate in water, and disperse ultrasonically for 10 minutes to obtain a mixed solution of sodium tetraborate and sodium dodecyl sulfate.

[0067] The graphene oxide aqueous solution and the mixed solution were mixed at a rotational speed of 10,000 rpm, and then reacted at 80° C. for 1 hour to obtain a foaming solution.

[0068] 1500 mg of sodium ascorbic acid was mixed with the foaming solution, reacted at 80° C. for 10 h, and then washed with 1 vol% ethanol aqueous solution to obtain graphene hydrogel.

[0069] The graphene hydrogel was frozen at -20°C for 20h, thawed to room temperature, and dried at 65°C for 24h to obtain graphene airgel powder.

Embodiment 1

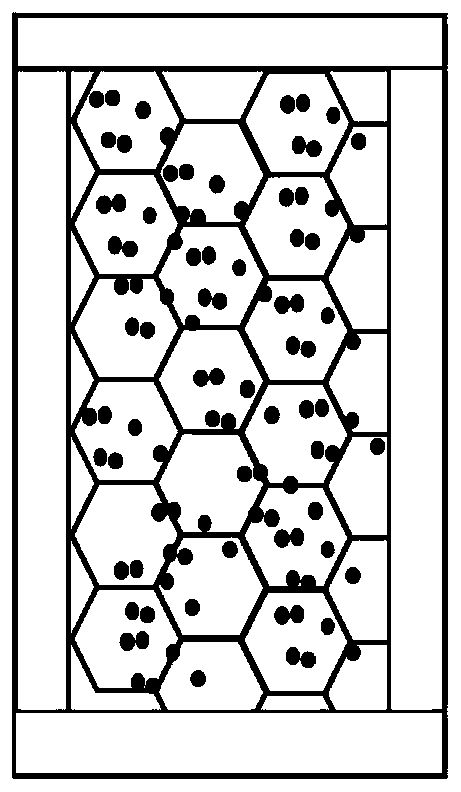

[0071] Prepare an aluminum alloy honeycomb sandwich (size 200×300×30mm, hole diameter 15mm). A layer of polyurethane adhesive is coated on the first surface of the aluminum alloy honeycomb sandwich to form an adhesive layer A. A calcium silicate board measuring 200 x 300 x 2 mm was attached to the adhesive layer A. 0.1MPa curing treatment for 30min. Set the density to 5kg / m 2 The graphene airgel powder (preparation example 1) is filled in the cavity structure of aluminum alloy honeycomb sandwich core. A layer of polyurethane adhesive is coated on the second surface of the aluminum alloy honeycomb sandwich to form an adhesive layer B. A calcium silicate board measuring 200 x 300 x 5 mm was attached to the adhesive layer B. 0.1MPa curing treatment for 2 hours, and curing for 12 hours after pressure release. The surroundings of the aluminum alloy honeycomb sandwich core are sealed with ceramic fiber strips to obtain an aluminum alloy honeycomb panel.

Embodiment 2

[0073] Prepare an aluminum alloy honeycomb sandwich (size 200×300×30mm, hole diameter 15mm). A layer of silicate adhesive is coated on the first surface of the aluminum alloy honeycomb sandwich to form an adhesive layer A. A calcium silicate board measuring 200 x 300 x 2 mm was attached to the adhesive layer A. 0.1MPa curing treatment for 30min. Set the density to 5kg / m 2 The graphene airgel powder (preparation example 1) is filled in the cavity structure of aluminum alloy honeycomb sandwich core. A layer of silicate adhesive is coated on the second surface of the aluminum alloy honeycomb sandwich to form an adhesive layer B. A calcium silicate board measuring 200 x 300 x 5 mm was attached to the adhesive layer B. 0.1MPa curing treatment for 2 hours, and curing for 12 hours after pressure release. The surroundings of the aluminum alloy honeycomb sandwich core are sealed with ceramic fiber strips to obtain an aluminum alloy honeycomb panel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com