Soybean protein and PVA (Polyvinyl Alcohol) blend fiber as well as preparation method and applications thereof

A technology of soybean protein fiber and soybean protein, applied in the direction of cellulose/protein conjugated artificial filament, wet spinning method, conjugated synthetic polymer artificial filament, etc., can solve the problem of large difference in expansion and failure of bicomponent fiber and other issues, to achieve the effect of improving tensile strength, low cost, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Soy protein powder preparation: First add 6%sodium hydroxide alkali solution to the cake powder to control the pH value of 10 (the solution is alkaline) to fully dissolve the protein in the water; then filter the residue removal, add methyl acid regulationThe pH value of the filter fluid is to the equal electric point (the pH value is between 4.4-4.8), the soy protein precipitation is precipitated, the normal pressure is filtered, and it is dried at 30-50 ° C to get the soybean protein powder.

[0024] Preparation of soybean protein solution: add soybean protein powder to the solvent of a acetate solvents, configure a solution with a concentration of 10 % (W / W), stir at 70 ° C for 24h, and the solution obtained at a centrifugal speed of 12000rpm 2 times, 10min each time, take each time, take each time, take each time, take 10min each time, take each time, take each time, take 10min each time, take each time, take each time, take each time, take 10min each time, take each ti...

Embodiment 2

[0028] Take the soy protein powder prepared in the Practice Example 1 and add a solvents with a concentration of 15 % (W / W) at the configuration of the concentration of 12H at 40 ° C.The upper layer of clearing solution is the soy protein solution (the concentration is 3%).

[0029] Take polyethylene glycol to add methic acid, stir at 30 ° C for 8h, get a polyvinol solution of 5%(W / W), and then add soybean protein solution, stir at a speed of 800 R / min at 30 ° C for 10 minutes, get soybeans to get soybeansProtein: PVA = 2: 8 The common solution.The obtained mixed solution is condensed to 14 WT%(W / W) at 70 ° C, that is, the spinning raw solution is obtained.

[0030] Smash the spinning lines and remove the vacuum and remove it. At 80 ° C saturated ammonium sulfate solidified bath, the obtained wire was cleaned twice in the ion water, stretched and wrapped, and finally dried at 50 ° C.product.

Embodiment 3

[0032] Take the soy protein powder prepared in the Practice Example 1 and add a solution with a concentration of 12 % (W / W) at a concentration of 12 % (W / W). Stir at 60 ° C for 24 hours.The upper layer of liquid is the soy protein solution (the concentration is 7%).

[0033] Take polyethylene glycol to add oxalic acid, stir at 30 ° C for 8h, get a polyvinol solution of 5%(w / w), and then add soybean protein solution. Under 30 ° C, stir at a speed of 800 R / min to mix 10 min for 10 min to get obtainedSoy protein: PVA = 3: 7 The common solution.The obtained solution is condensed to 10 % (W / W) at 40 ° C to obtain the spinning raw solution.

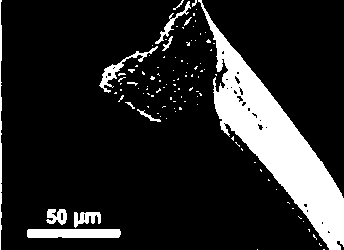

[0034] Smoil the spinning lines to remove the vacuum, and the saturated sodium sulfate solidarity bath at 20 ° C is pumped. After washing the obtained wire twice in the ion water, it stretchs and wraps it.See Fiber's scanning electron microscopy photos figure 2 Essence

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com