Vehicle-mounted hydrogen production device

A technology for hydrogen production devices and vehicles, which is applied in the directions of power plant, hydrogen, and power plant gas intake, etc., achieves the effects of compact overall structure, improved service life, and avoided catalyst deactivation problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

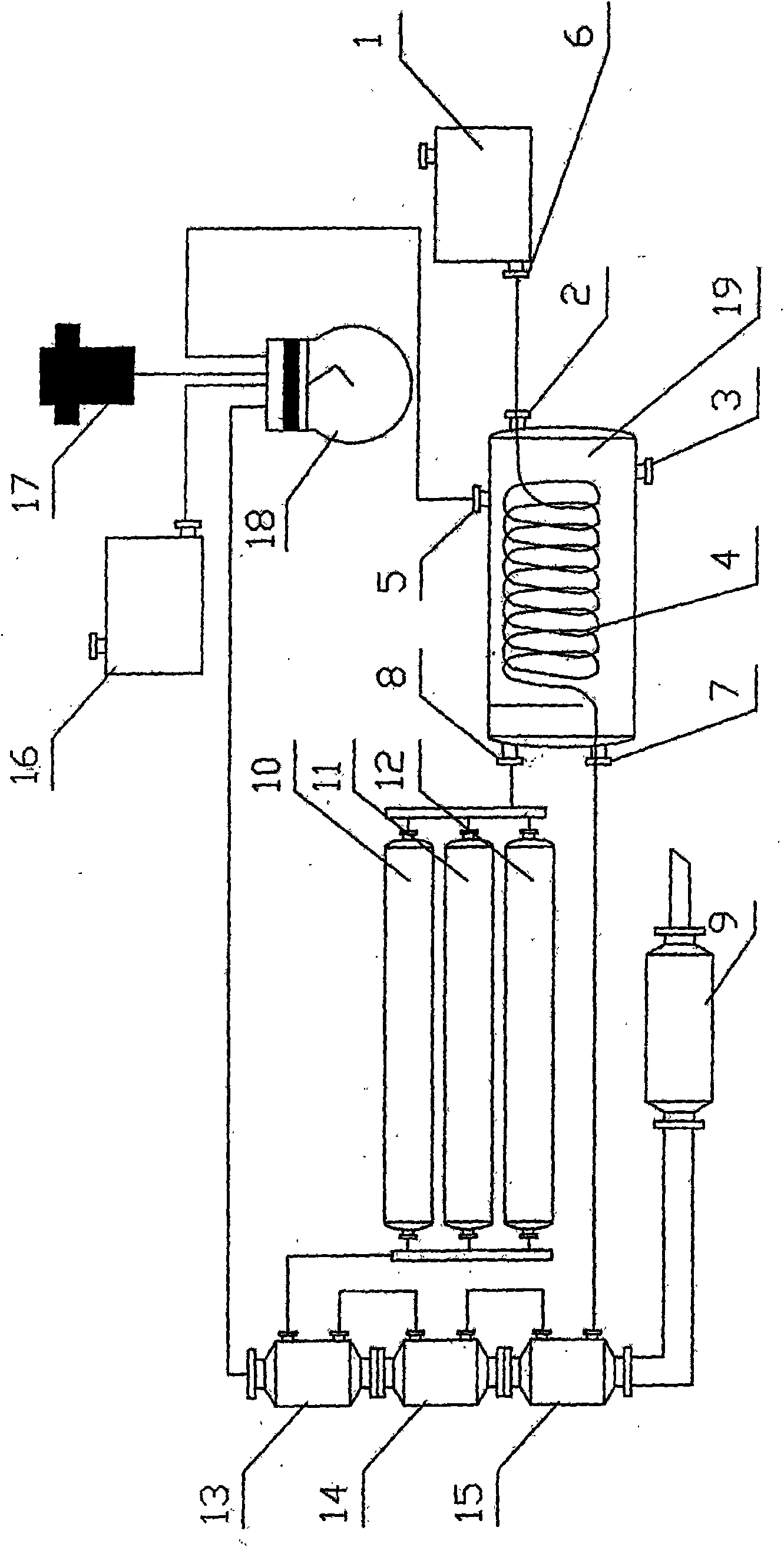

[0028] Such as figure 1 Shown, the present embodiment comprises the alcohol tank 1 of adorning methanol or ethanol, and the alcohol pipe connected with the alcohol outlet 6 of the alcohol tank 1 passes through the gas-water separator 19 inner cavity from the gas-water separator inlet 2, and is connected with the gas-water separator. The heat exchange tube 4 in the inner chamber of the gas-water separator 19 is connected to the alcohol end, and the alcohol outlet 7 of the gas-water separator passes through the alcohol tube. The heat exchange tube 4 is in a spiral shape, which is beneficial to the heat exchange between the alcohol and the cracked gas in the heat exchange tube.

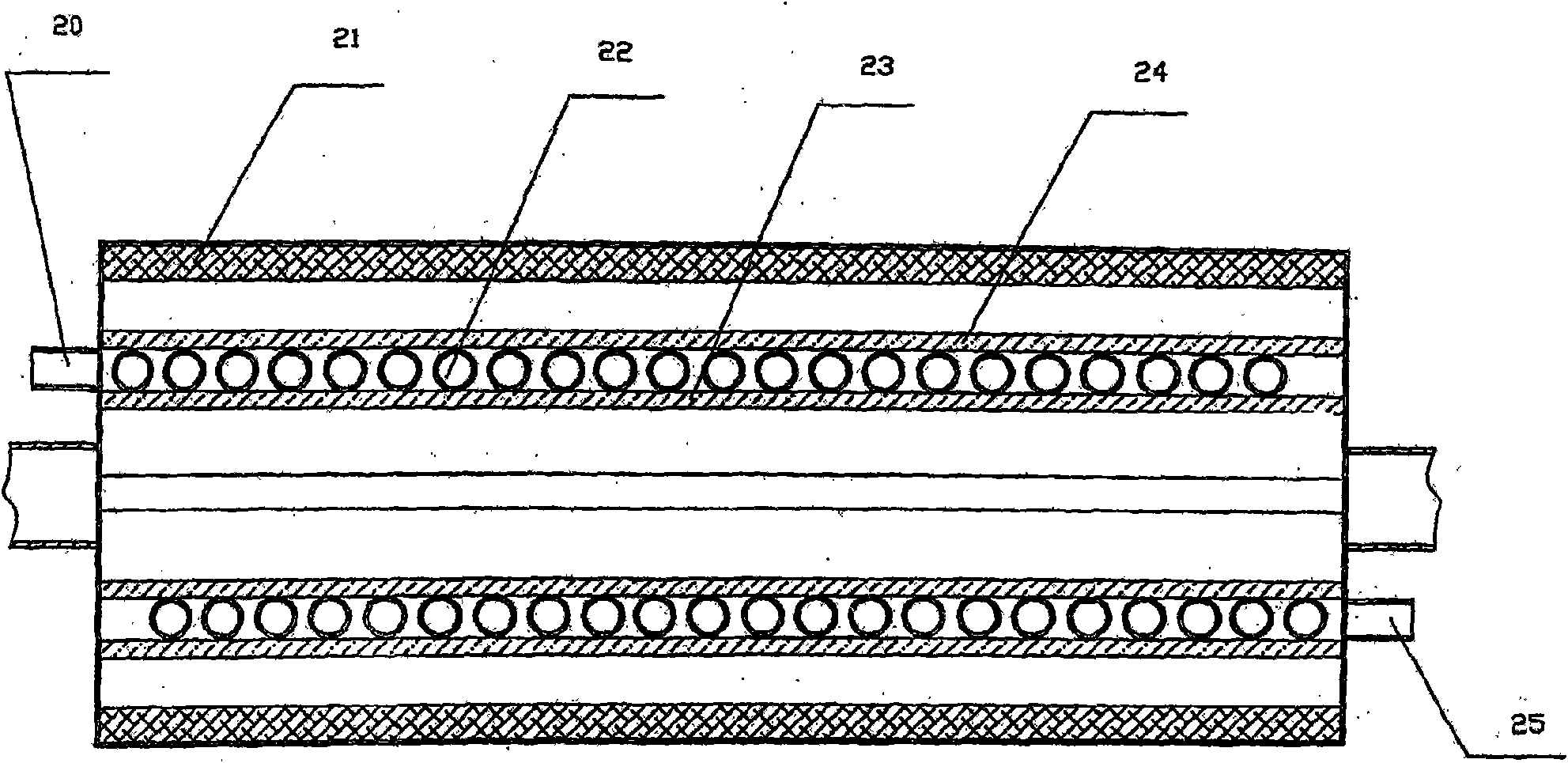

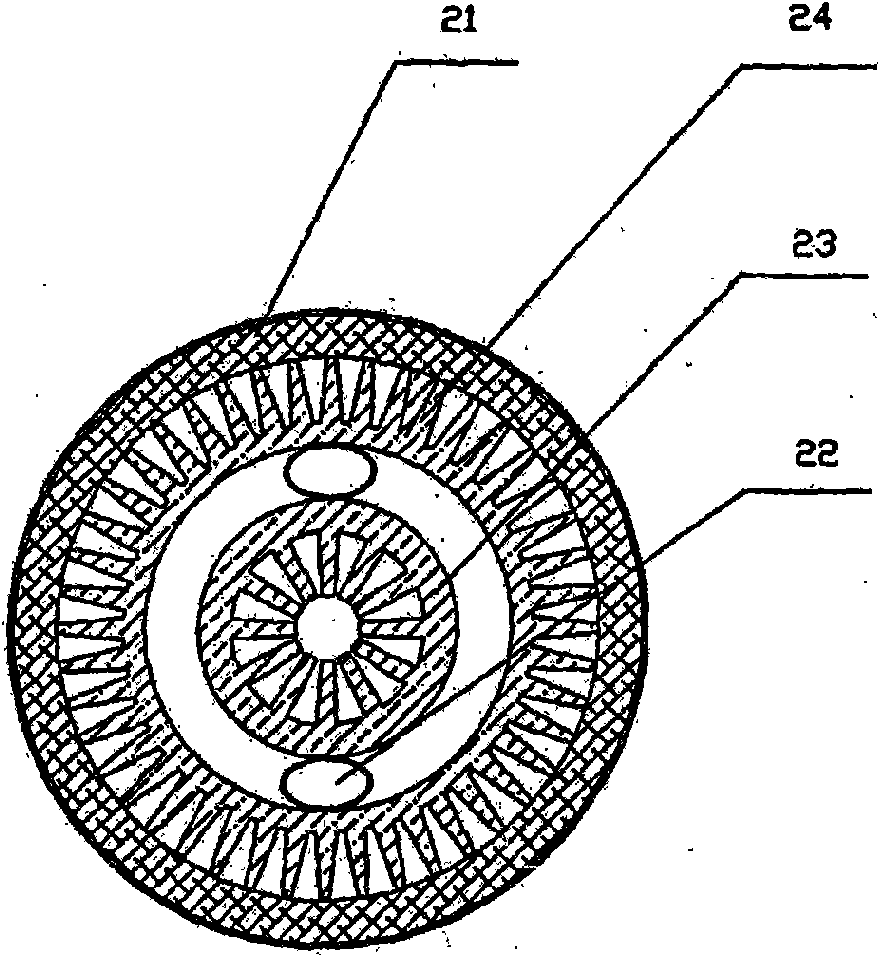

[0029] Such as figure 2 , 3 As shown, each heater unit includes a cylindrical casing 21 and an internal thermal storage body 23 inside the casing 21 . The housing 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com