Coke making method by adding biomass energy to mixed coal

A biomass energy and biomass energy technology, applied in coke ovens, energy input, petroleum industry, etc., can solve the problems of few coking coal and fat coal resources, less than 20 years old, and low technical content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

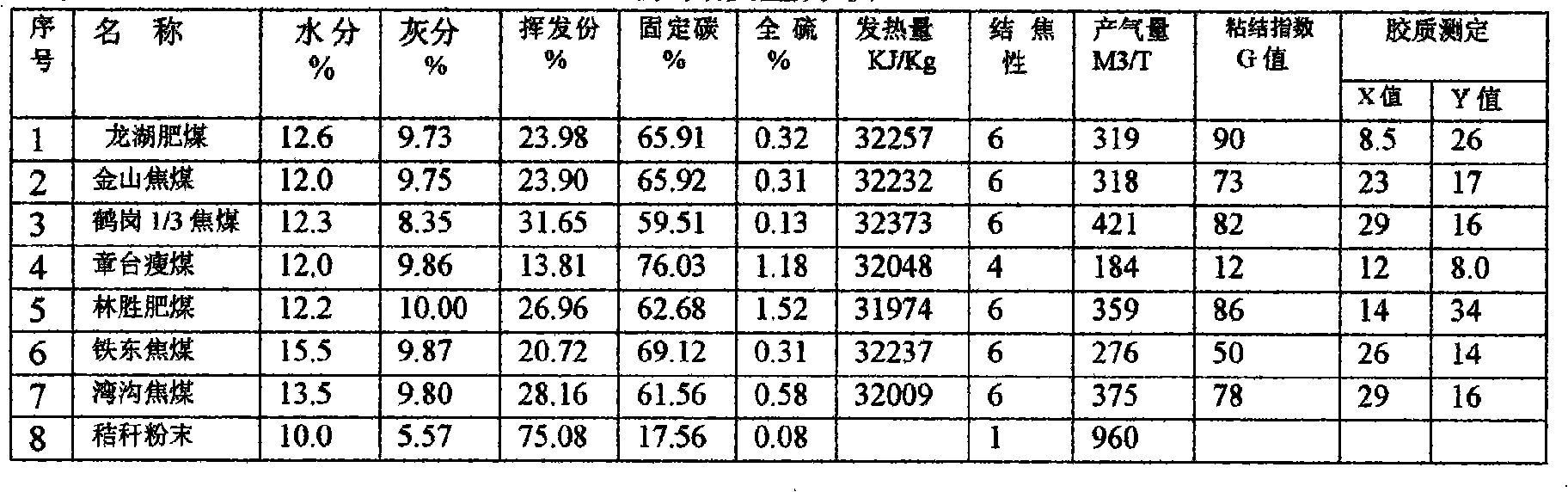

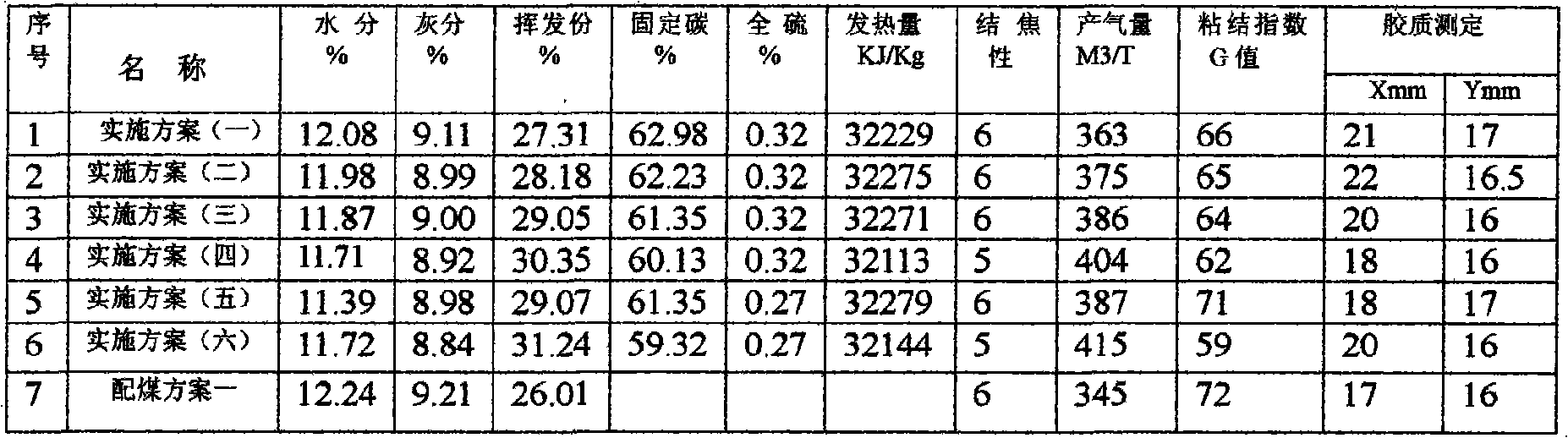

[0026] In the following, combined with the process flow chart and related analysis data, several groups of coal blending schemes are selected based on the resource status of a single coking coal, and are specifically explained as follows in the form of a list;

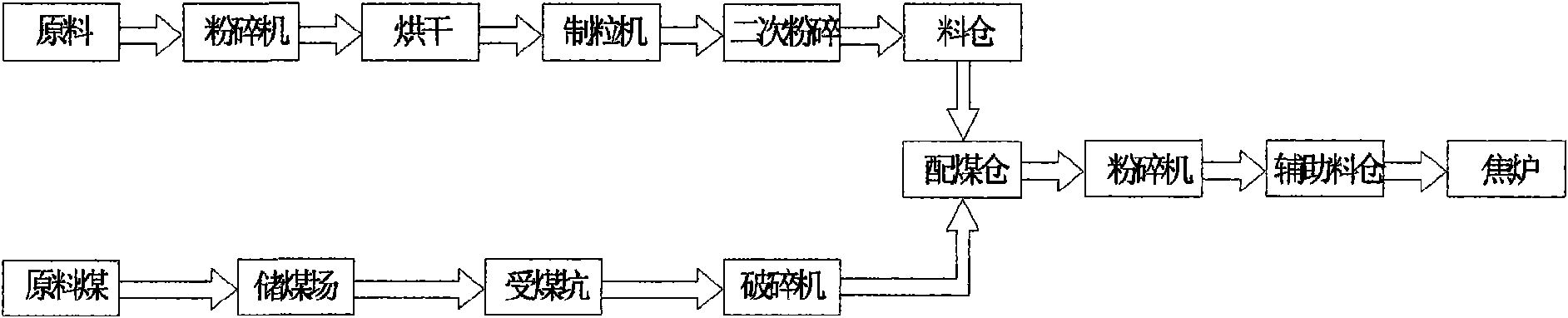

[0027] The coal blending feeding system adopts the coal blending feeding process of first blending coal and then crushing. The raw coal passes through the pit from the coal storage yard, passes through the conveying belt to the crusher, and enters the coal blending bin after being crushed. It goes down to the transport belt through the shaking feeder and nuclear scale, passes through the transfer station to the pulverizer and pulverizes until the particle size is less than 3mm, sends it to the auxiliary silo and then puts it into the coke oven carbonization chamber; the straw raw material particles come down through the silo and coal blending silo, The shaking feeder and nuclear scale are mixed with the mixed coal, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com