Ni-P amorphous/MoS2 composite membrane for preventing cold welding effect under high vacuum environment

A composite film and high vacuum technology, applied in the field of composite film, can solve the problems of unreported, unfavorable films, etc., and achieve the effects of simple process, low price and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

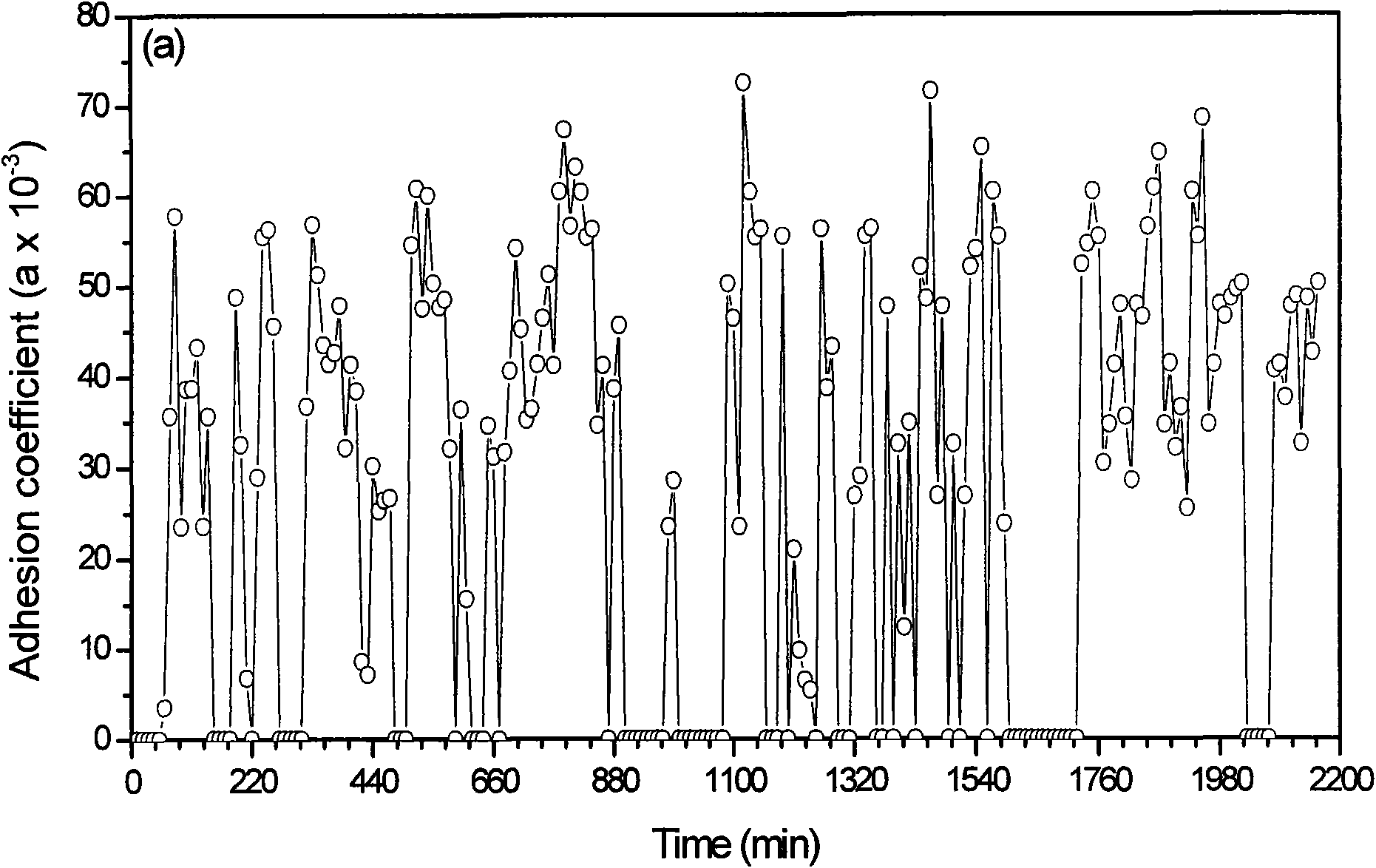

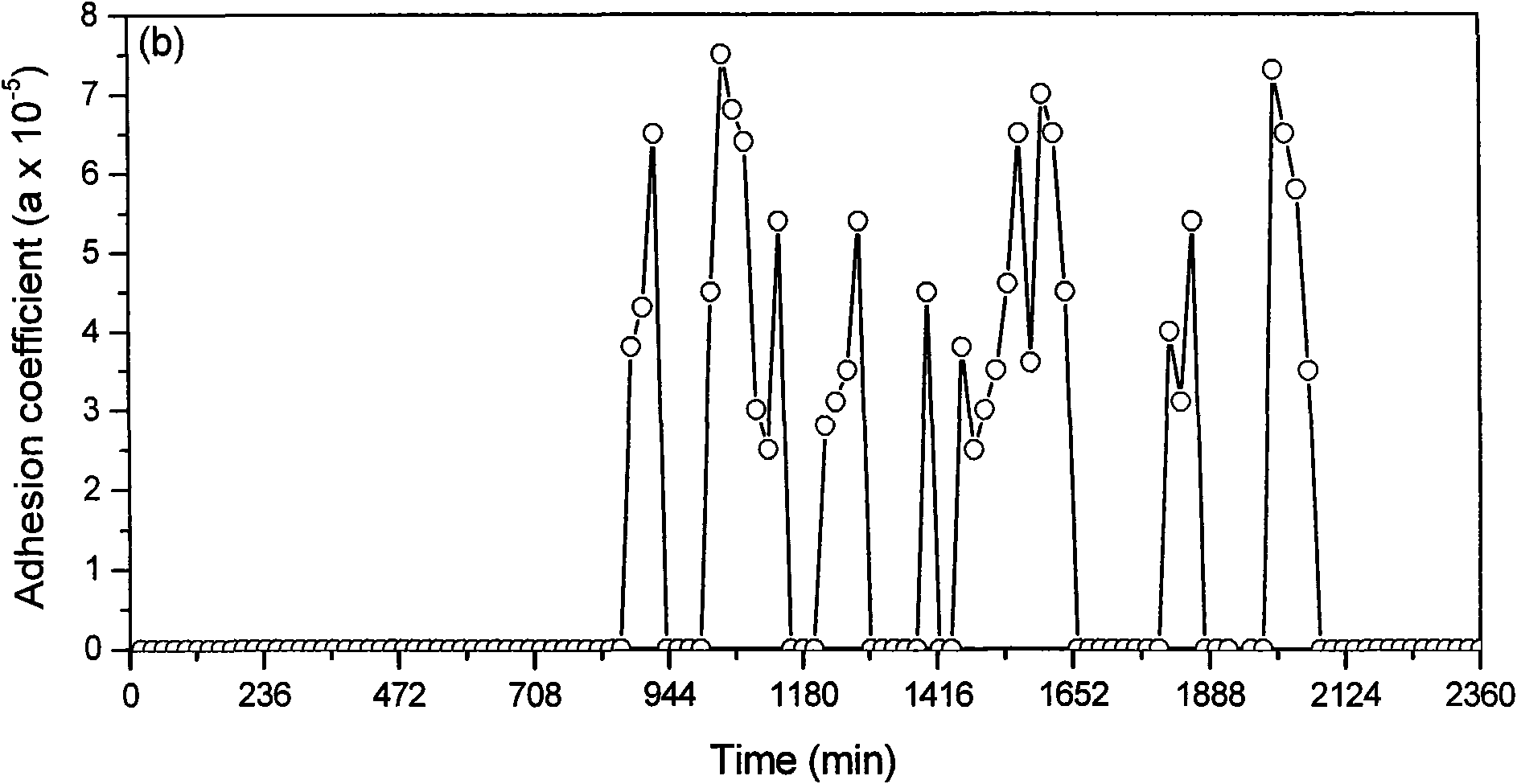

Image

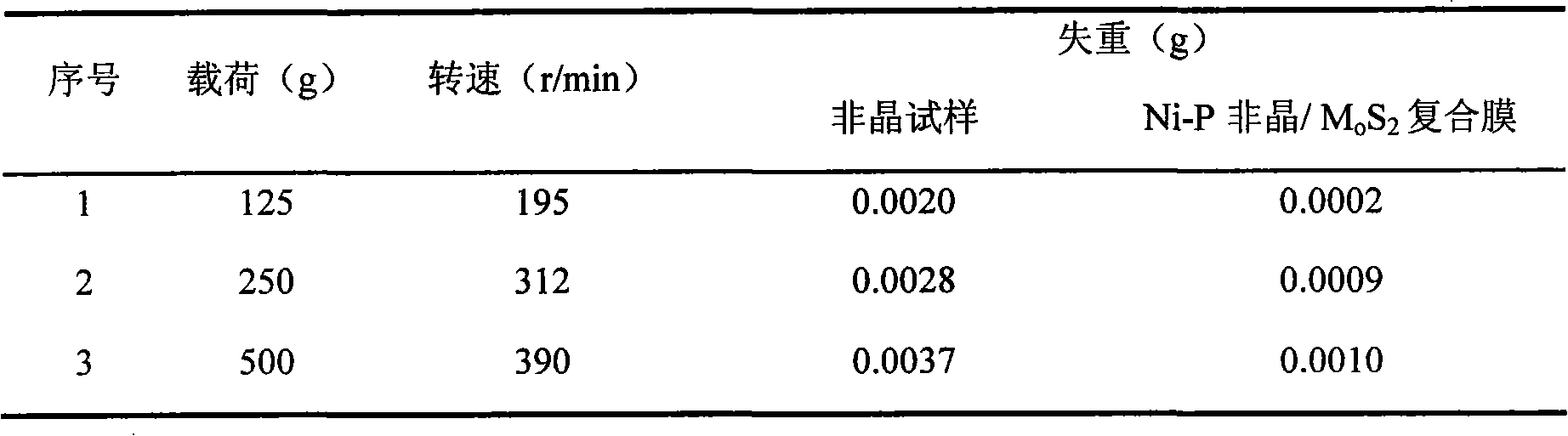

Examples

Embodiment 1

[0010] Space separation system clasps require surface treatment to prevent space vacuum cold welding and to be able to work for a long time. Therefore, a Ni-P amorphous / MoS2 composite film was prepared on the surface of the amorphous alloy to prevent the cold welding effect in a high vacuum environment.

[0011] After degreasing and acid etching, the amorphous alloy is plated on the substrate by electroless plating method to prevent cold welding effect in high vacuum environment Ni-P amorphous / M o S 2 composite film. Its plating method is as follows:

[0012] (1) prepare electroless plating solution and its composition is: nickel sulfate 22g / L, sodium hypophosphite 25g / L, sodium acetate 20g / L, sodium citrate 35g / L, lactic acid 6ml / L, nanomolybdenum disulfide 5g / L ;Adjust the pH value of the plating solution with ammonia water, pH=8;

[0013] (2) Degreasing, activation, and pre-plating of plated parts;

[0014] (3) The plating solution is heated to 90°C, and the plating ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com