Combined wind power speed increaser

A speed-increasing box and combined technology, which is applied in wind power generation, transmission boxes, wind engines, etc., can solve the problems of difficult production maintenance, increase in speed-up boxes, and inconvenient transportation for manufacturers, and achieve low maintenance and repair costs. Failure rate, effect of ease of handling and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

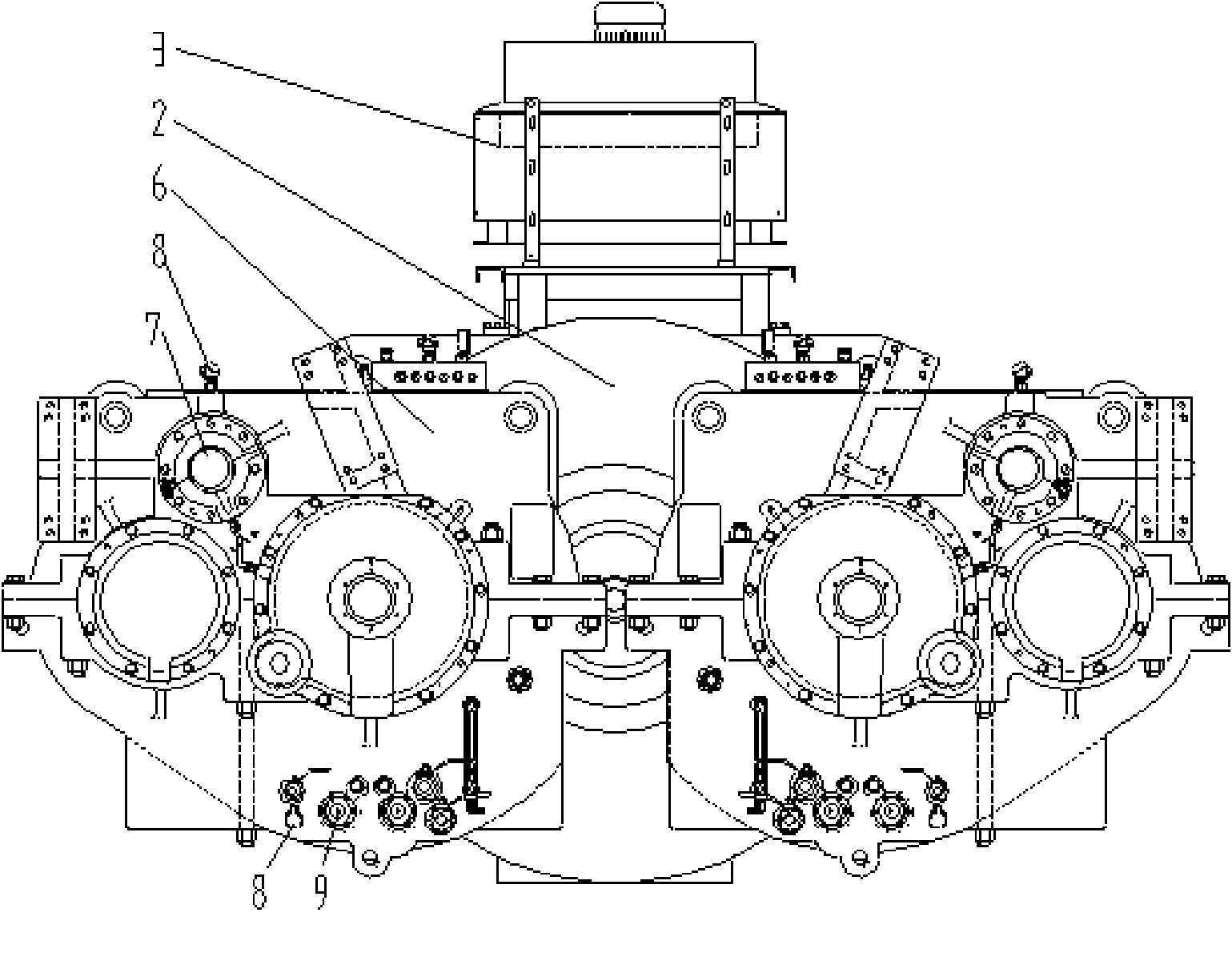

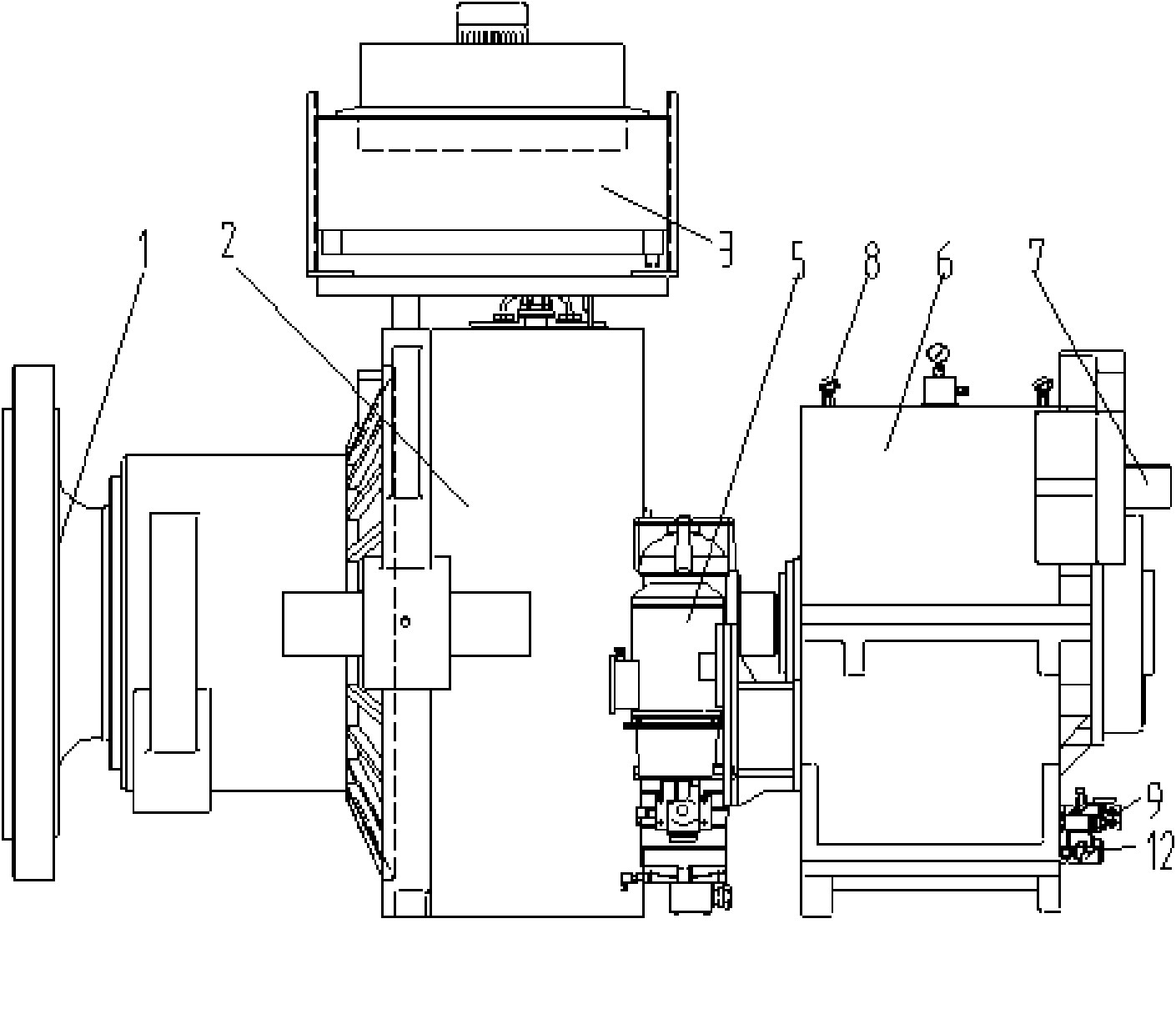

[0027] see Figure 1 to Figure 4 , The combined wind power gearbox in this embodiment includes a primary speed increasing unit 2, an air cooling device 3, a coupling 4, an oil supply filtering device 5, a temperature control device and two secondary speed increasing units 6. The first-level speed-up unit 2 in the present embodiment comprises a first-level box body, a main shaft 1, a large ring gear 10 and two gear shafts 11, and the number of the gear shafts 11 and the number of the second-level speed-up units 6 in the present invention are the same, because in this embodiment two secondary speed increasing units 6 are provided, so the primary speed increasing unit 2 is provided with two gear shafts 11 . There is a wind wheel hub on the main shaft 1 in this embodiment, so that the use of the wind power speed-up box in this embodiment is more convenient, and the wind wheel in the wind power generating set can be directly installed on the wind wheel hub. Of course, this The mai...

Embodiment 2

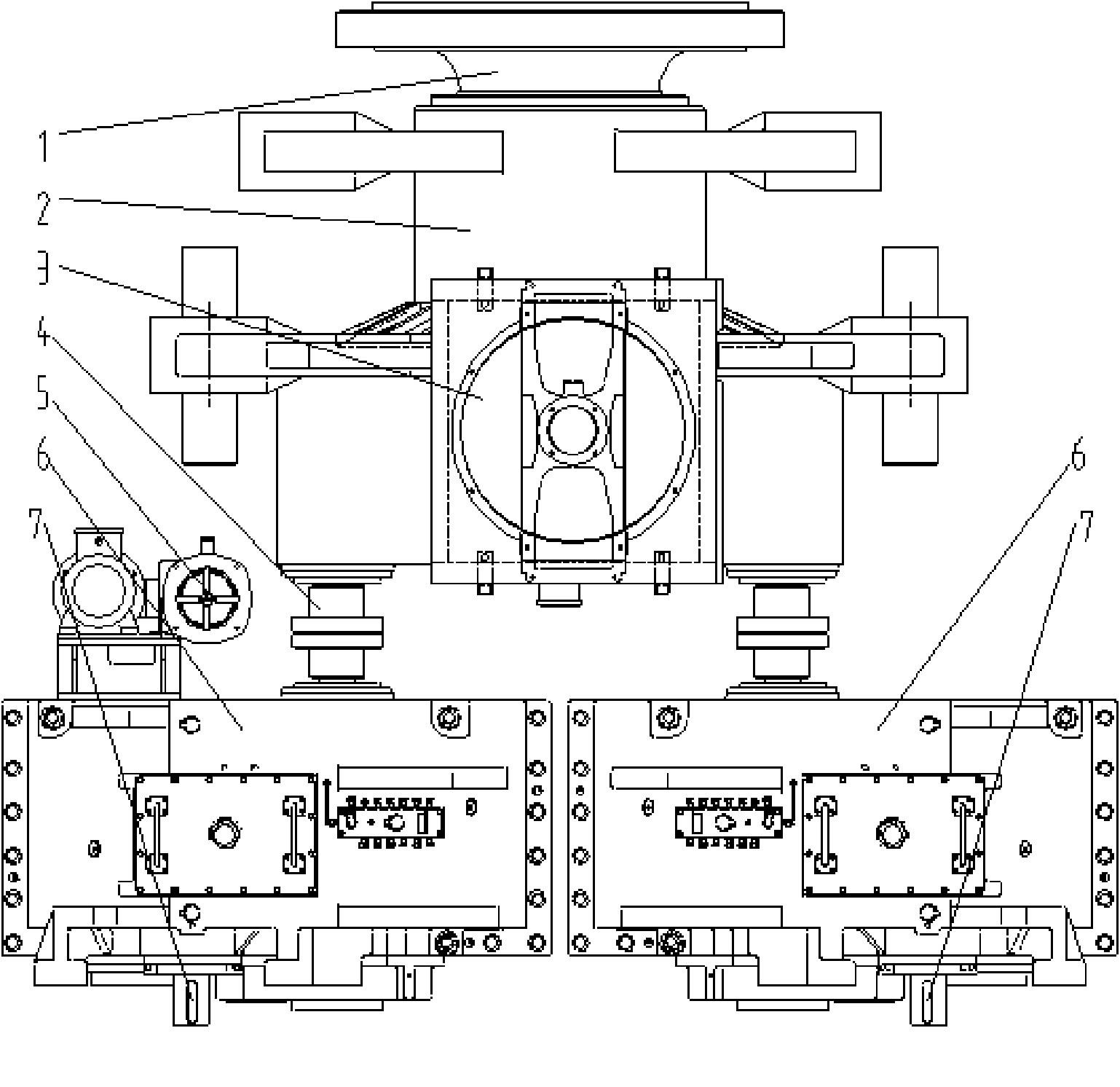

[0045] see Figure 5 , the combined wind power speed-up box in this embodiment is compared with that in Embodiment 1. The difference is that four secondary speed-up units 6 are arranged in this embodiment, and a Four gear shafts 11 are evenly distributed on the periphery of the large ring gear 10 , and the four gear shafts 11 are all meshed with the large ring gear 10 . Other structures in this embodiment are similar to those in Embodiment 1, and will not be described in detail here.

[0046] In this embodiment, one primary speed-up unit 2 is connected with four secondary speed-up units 6, and this combined wind power speed-up box is called a combination form of one driving four.

[0047] The present invention can be seen from the above embodiments, compared with the integral wind power speed-up box, the present invention has the following advantages:

[0048] (1) The reduction of wearing parts such as planetary wheel bearings is conducive to reducing the failure rate and mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com