High-purification automatic impurity-removing and tea-sterilizing process

An automatic technology for tea, which is applied in the field of high-purification and automatic removal and sterilization of tea, can solve the problems such as the lack of in-depth research on the removal of non-tea inclusions, hidden dangers of harmful microorganisms and heavy metal pollution, and the huge distance difference between non-tea inclusions. , to achieve the effect of maintaining nutrients and color, high tea-making efficiency, and controlling secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

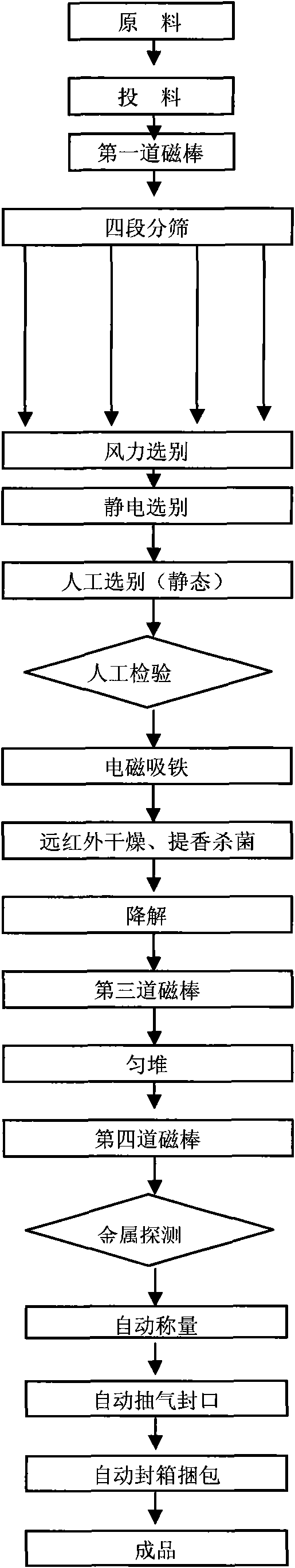

[0021] Such as figure 1 As shown, the tea high-purification automatic deodorization and sterilization process of the present invention specifically includes the following steps: the original tea is put into the equipment for preliminary screening steps, including the first magnetic bar screening, four-stage wind sieving, electrostatic sorting and second screening. Two magnetic bar screenings, the first magnetic bar screening removes the basic metal debris or magnetic objects in the tea leaves; the combination of the four-stage sub-sieving and the four-speed corresponding wind speed is used to sort the tea leaves, and the tea raw materials are used for different purposes. The number of round sieves is divided into three dimensions from top to bottom, and the tea leaves are divided into four sections according to the size of the upper and lower limits within the standard limit, and then enter four different wind separators, and use four different wind powers to carry out finer la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com