Mechanical cabinet position converter of gas tank

A gas tank, machinery technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

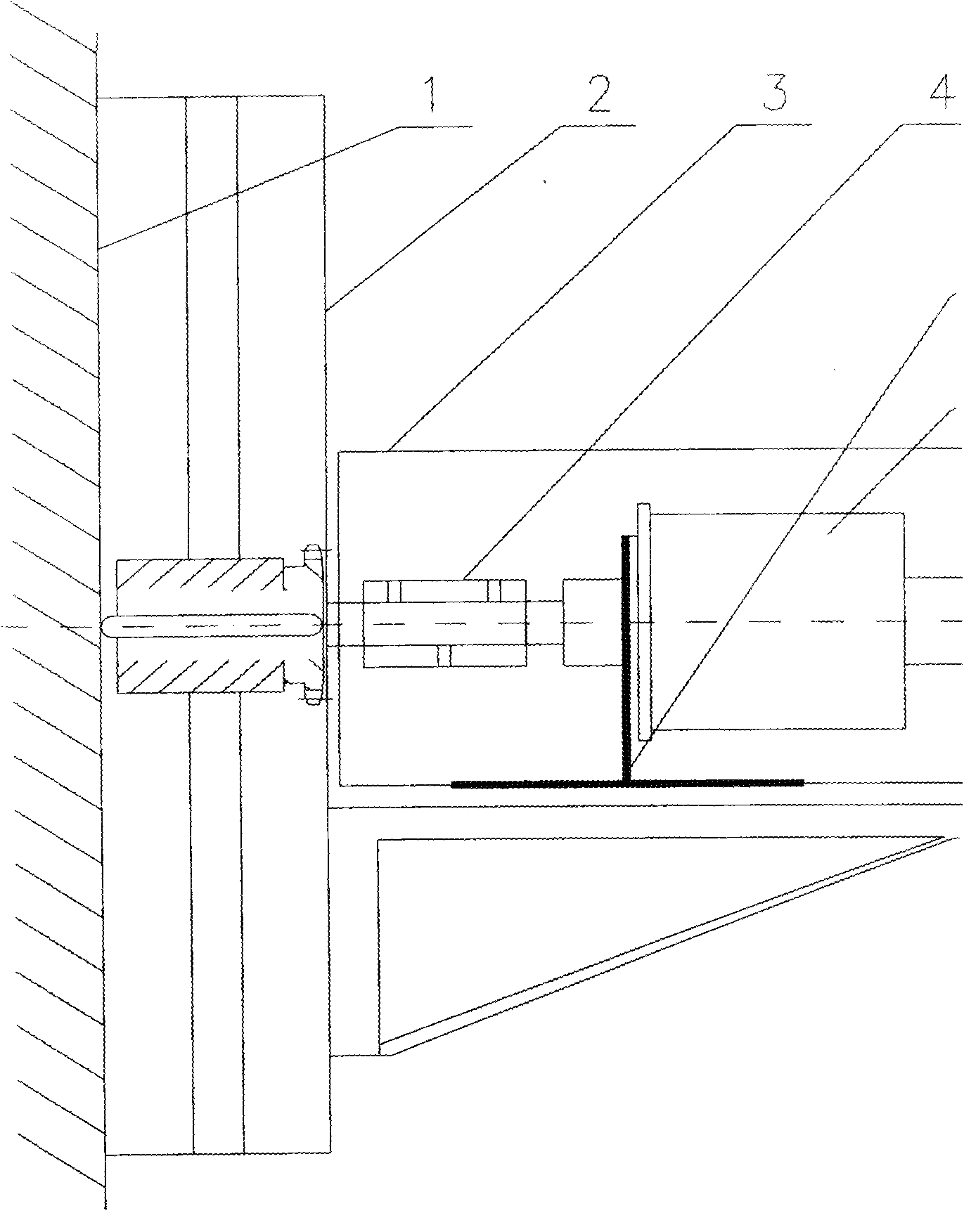

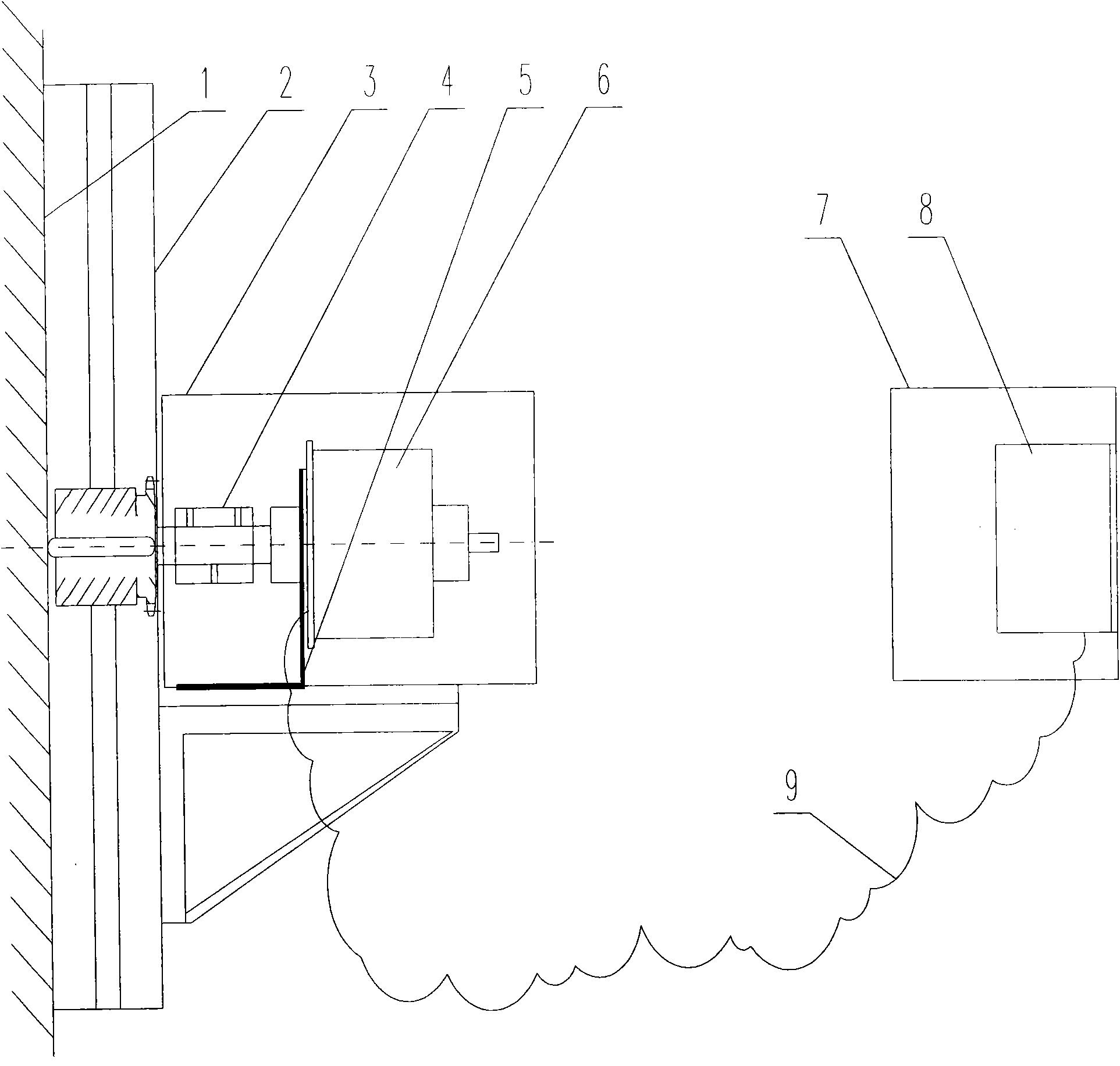

[0017] Attached below figure 2 Specific embodiments of the present invention are further described:

[0018] The mechanical counter meter 2 is installed on the steel structure 1 of the gas cabinet corridor, the encoder 6 installed on the bracket 5 in the protective cover 3 is connected to the mechanical counter meter 2 through a flexible coupling 4, and the signal converter 6 is connected to the explosion-proof special The cable 9 is connected with the digital-to-analog converter 8 installed in the explosion-proof box 7 .

[0019] The present invention adopts the combination measurement method of encoder + flexible coupling + bracket + external digital-to-analog converter and explosion-proof box to convert the signal of the mechanical counter meter of the gas cabinet, and converts the signal of the mechanical counter meter into a standard 4~ 20mA DC is sent to the basic automatic control system to better monitor the safe operation of the gas cabinet. This new mechanical cab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com