Current sensor for polluted insulator leakage of AC high-voltage electric transmission line

A high-voltage transmission line, leakage current technology, applied in the direction of measuring current/voltage, parts and instruments of electrical measuring instruments, etc. The problems of inconvenient loading and unloading of the annular iron core can achieve the effect of good linearity, high mechanical strength, convenient loading and unloading and operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

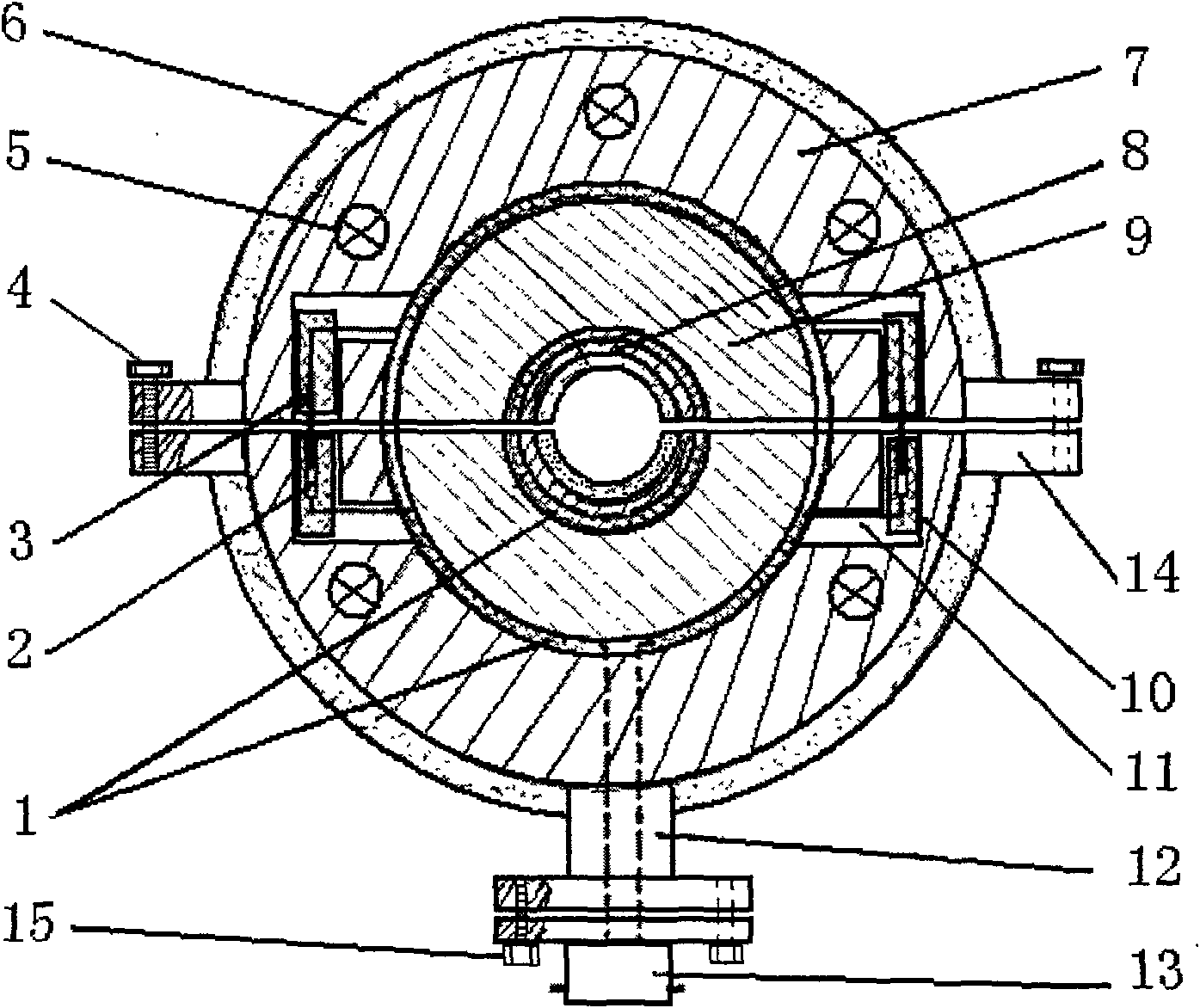

[0035] Such as figure 1 As shown, an AC high-voltage transmission line dirty insulator leakage current sensor mainly includes a Rogowski coil with an iron core, a shielding shell, and a coaxial cable connector 13 . The Rogowski coil is composed of an iron core 9 and a winding 1. The characteristics are: the iron core 9 is two semicircular annular iron cores, the material of the two semicircular annular iron cores 9 is ferrite, and the inner diameter of each semicircular annular iron core 9 is 44mm. , Outer diameter is 67mm, thickness is 19mm. Two semi-circular iron cores 9 are combined into one annular iron core 9. The winding 1 is divided into two windings: a copper enameled wire with a diameter of 0.65 mm is tightly wound on the upper semi-circular iron core 9 to form a winding with 65 turns, and at the outlets of the winding 1 at both ends of the iron core 9, respectively A copper pin 3 is welded with a copper enameled wire head; a copper enameled wire with a diameter of ...

Embodiment 2

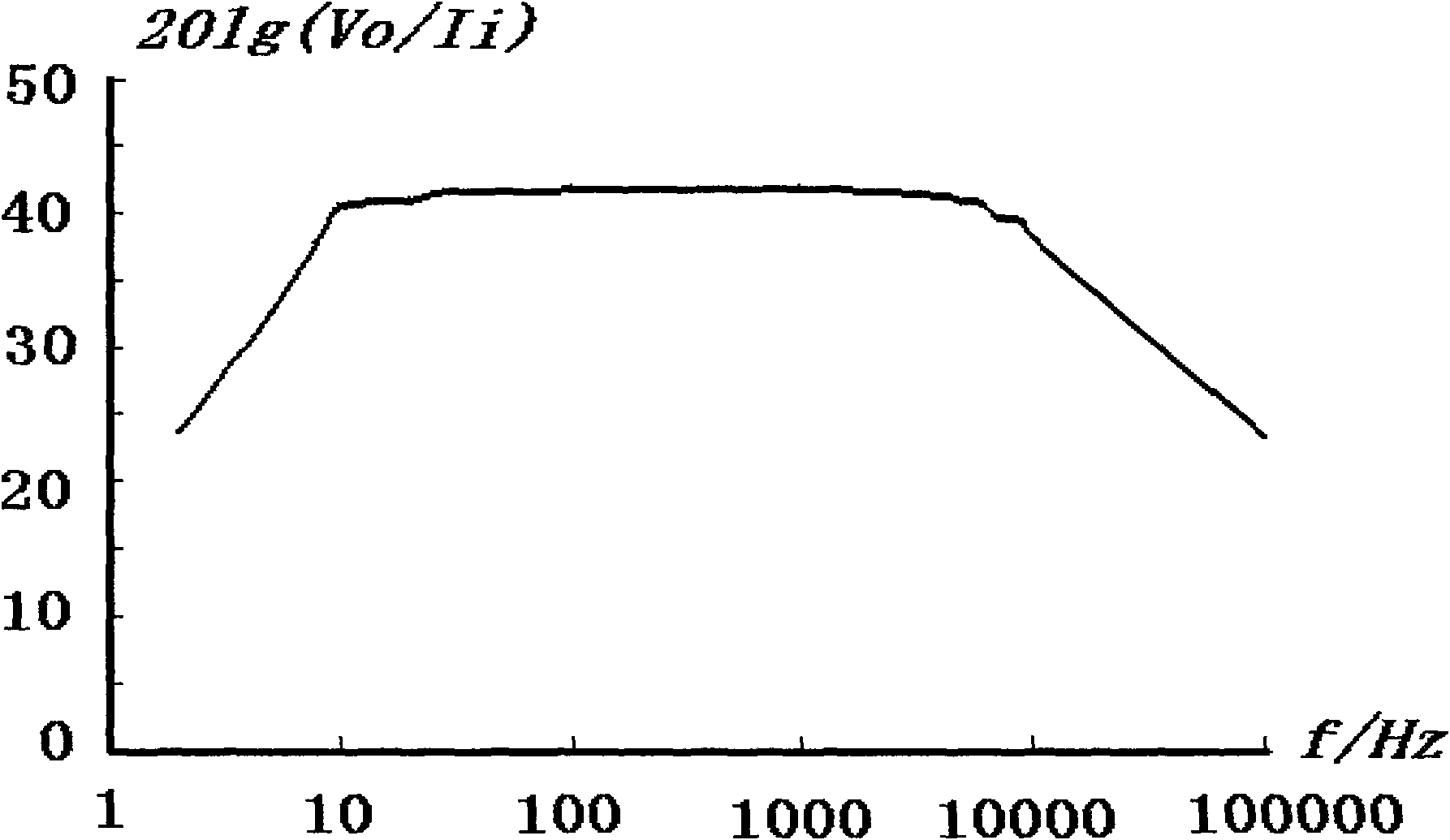

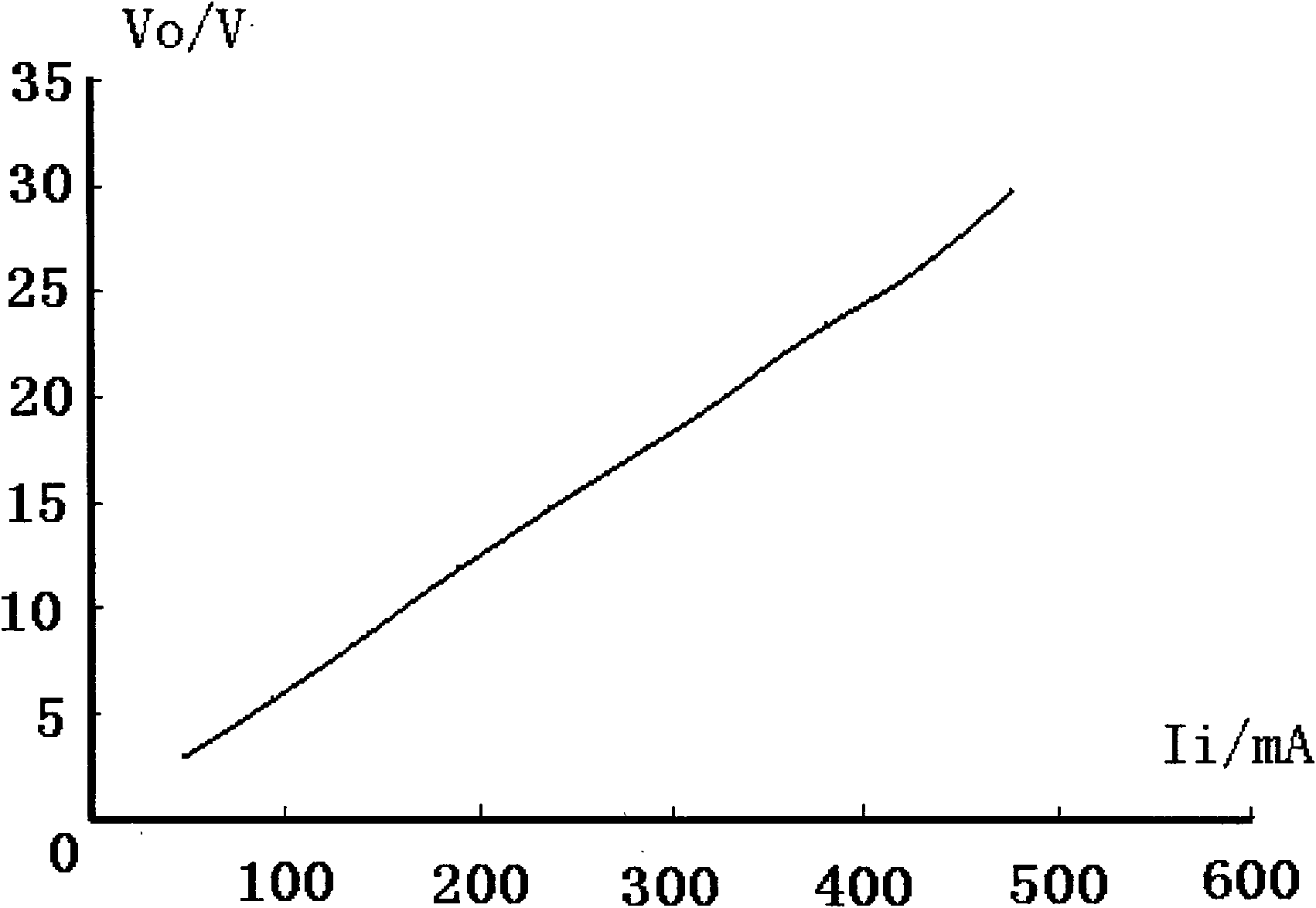

[0037] An AC high-voltage transmission line dirty insulator leakage current sensor, the same as embodiment 1, wherein: the inner diameter of the two semicircular annular iron cores 9 is 43mm, the outer diameter is 66mm, and the thickness is 18mm. The diameter of the winding 1 enameled wire is 0.6mm; the copper shielding shell The inner diameter of the hollow groove is 33mm, the outer diameter is 98mm, and the height is 28mm. The thickness of the inner wall 8 of the hollow groove is 4mm, and the thickness of the outer wall 7 is 10mm; the inner diameter of the upper cover of the copper shielding shell is 33mm, the outer diameter is 98mm, and the thickness is 4mm. ; On the inner wall 8 of the hollow groove of the copper shielding shell, a gap of 1.2mm is opened; the thickness of the outermost epoxy resin layer 6 of the copper shielding shell is 5mm; The value range is 0.5mA~500mA, the frequency range is 10Hz~30kHz, and the sensitivity is about 59.4mV / mA.

Embodiment 3

[0039] An AC high-voltage transmission line dirty insulator leakage current sensor, the same as embodiment 1, wherein: the inner diameter of the two semicircular annular iron cores 9 is 42mm, the outer diameter is 65mm, and the thickness is 17mm; the diameter of the enameled wire of the winding 1 is 0.5mm; the copper shield The inner diameter of the hollow groove of the shell is 30mm, the outer diameter is 95mm, and the height is 26mm. The thickness of the inner wall 8 of the hollow groove is 3mm, and the thickness of the outer wall 7 is 8mm; the inner diameter of the upper cover of the copper shielding shell is 30mm, the outer diameter is 95mm, the thickness 3mm; on the inner wall 8 of the hollow groove of the copper shielding shell, a gap with a width of 1.0mm is opened; the thickness of the outermost epoxy resin layer 6 of the copper shielding shell is 4mm; the winding number of one turn of the leakage current sensor is 150 turns, The detection current amplitude range is 0.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com