Dynamic soft-measuring method of ingredients of regenerated flue gas generally regenerated by catalytic cracking device

A technology for regenerating flue gas and cracking devices, which is applied in the direction of electrical program control, comprehensive factory control, and comprehensive factory control, and can solve problems such as model structure correction, expensive online analyzer, and unsatisfactory measurement results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0136] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

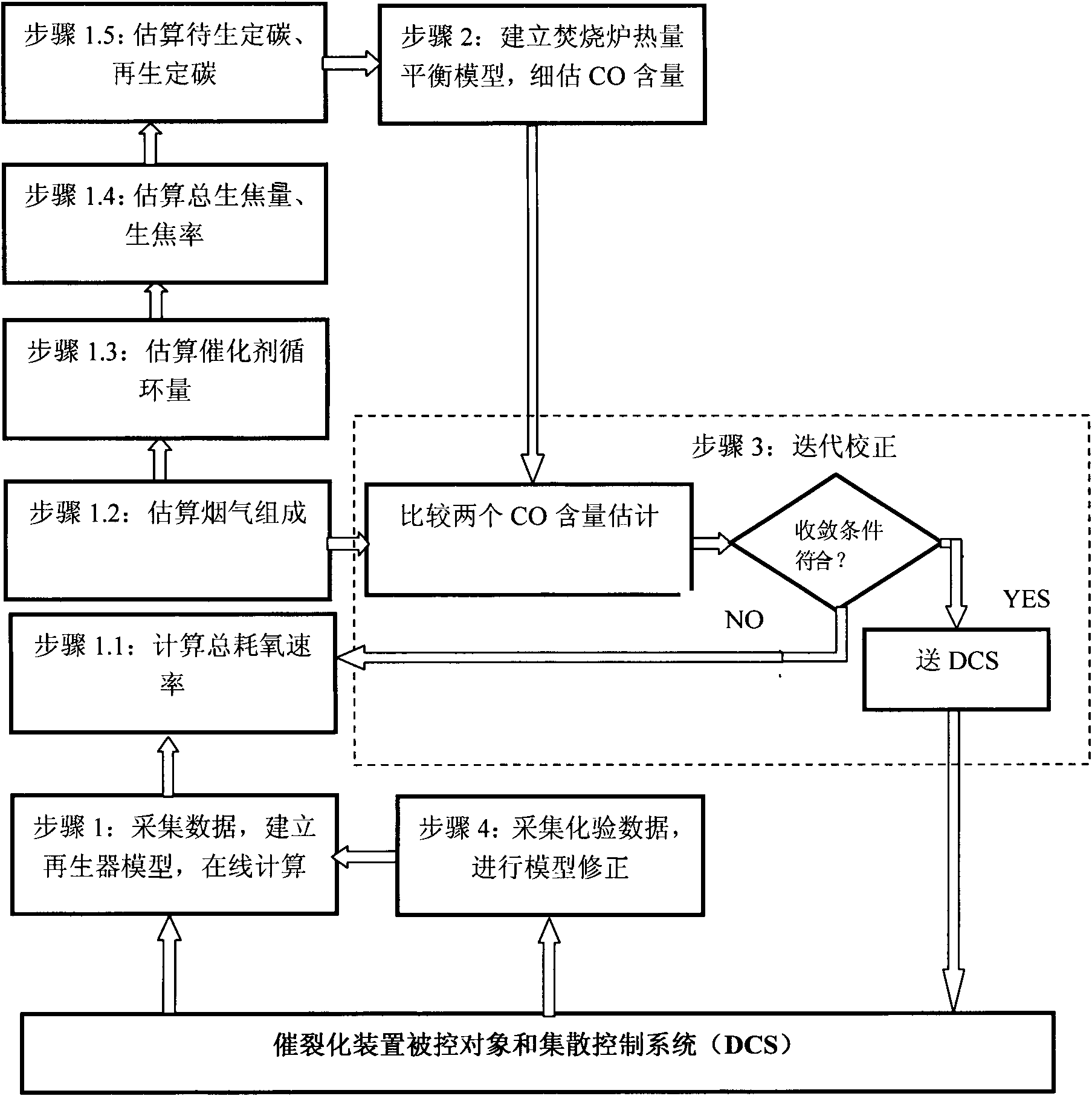

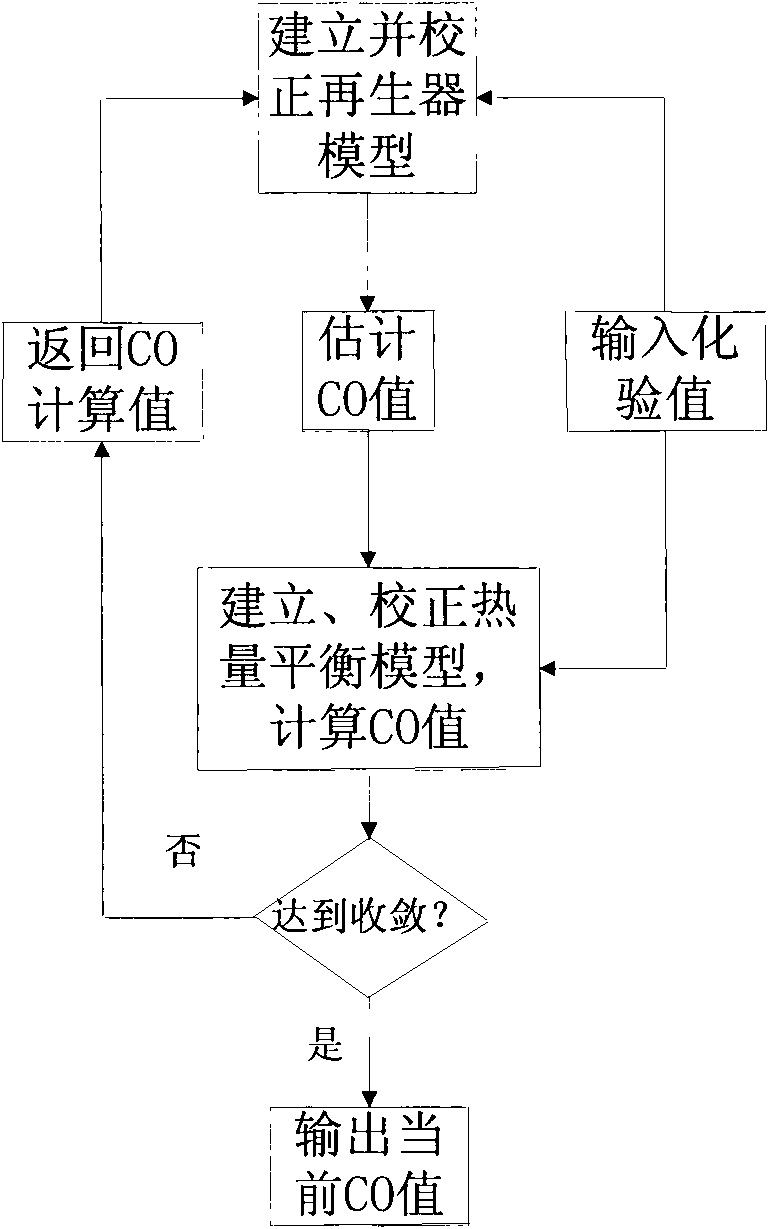

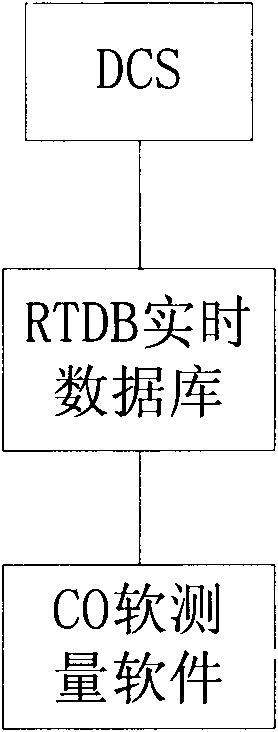

[0137] The present invention is characterized in that: the method adopts the joint utilization of the regenerator mechanism analysis dynamic model and the heat balance of the external CO incinerator part incinerator, and the special method of combining the online real-time process calculation technology based on the mechanism analysis with the dynamic model observation calculation, Realized the dynamic soft sensing of the unmeasurable variables of the regenerator of the catalytic cracking unit, including: 1) the establishment of a dynamic model for the analysis of the internal mechanism of the regenerator, 2) the establishment of the heat balance model of the CO incinerator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com