Exenatide release microsphere preparation, preparation method and application thereof

A technology of slow-release microsphere preparations and exenatide, which is applied in the direction of pharmaceutical formulations, peptide/protein components, and medical preparations of non-active ingredients, which can solve the problems of poor patient compliance and unacceptability, and reduce drug administration. Frequency, weight control, effect of improving treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

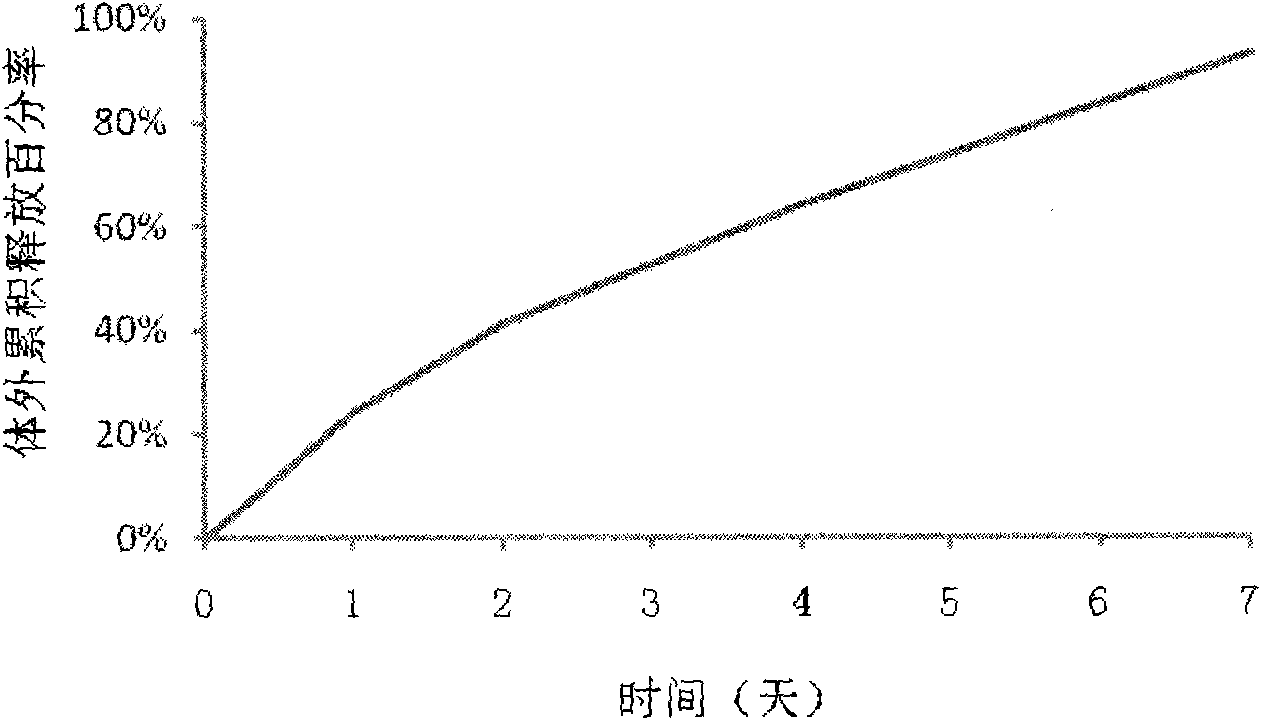

[0077] Example 1 Preparation of Exenatide Sustained-release Microspheres by W1 / O / W2 Solvent Evaporation

[0078] Dissolve 800mg of PLGA (RG502H, LA:GA=50:50, Mw=10000) in 3.0ml of dichloromethane to make an oil phase, dissolve 20mg of exenatide in 0.05ml of double distilled water (containing 12.5mg of gelatin) Form the inner water phase, add it to the above oil phase, ultrasonic emulsification, form W1 / O colostrum, put 50ml of 2% PVA solution in a stirring container, quickly add the colostrum to the outer water under high-speed stirring (1200rpm) Fully homogenize in the phase, after three minutes, reduce the rotating speed to 400 rpm, add 0.75% polyvinyl alcohol solution, stir at room temperature for 4 hours, centrifuge and wash the microspheres after hardening, and freeze-dry. The encapsulation efficiency of the exenatide microspheres is 90%, and the particle size is less than 100 μm.

Embodiment 2

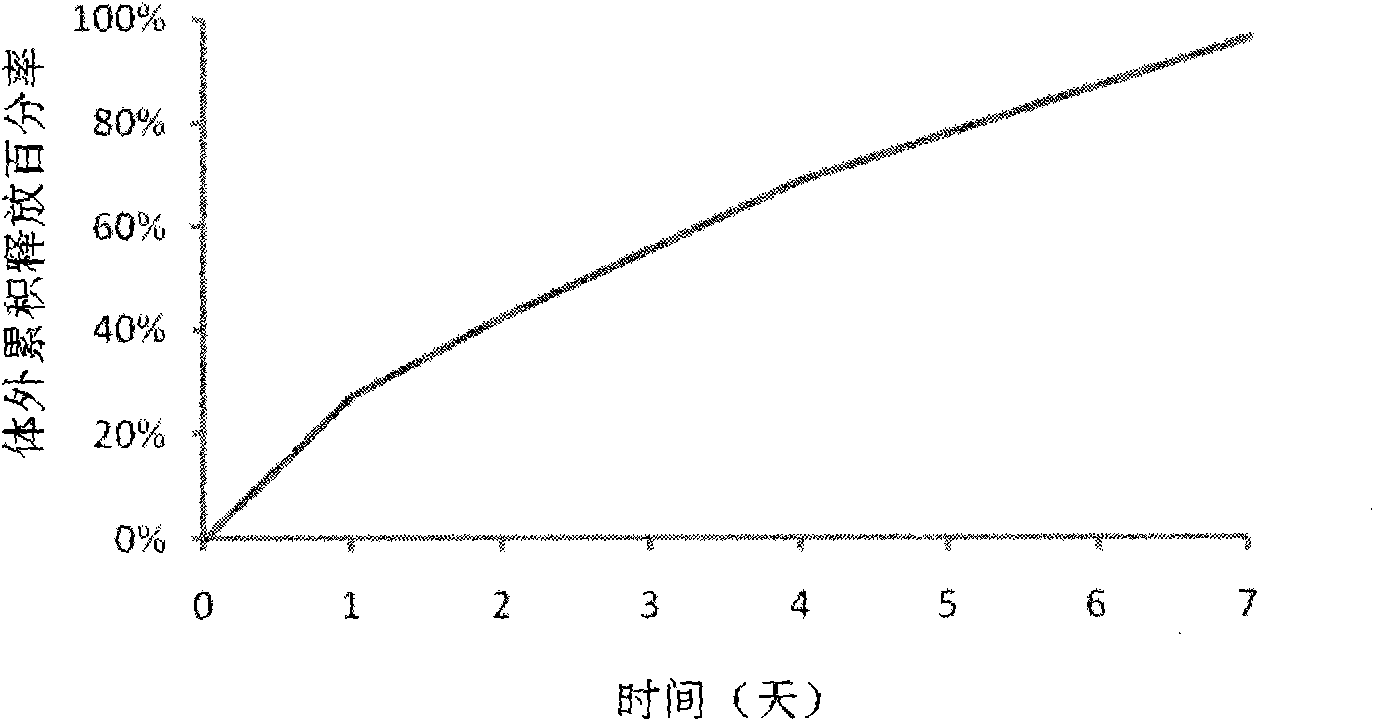

[0079] Example 2 Preparation of Exenatide Sustained-release Microspheres by W1 / O / W2 Solvent Evaporation

[0080] Dissolve 250mg of PLGA (RG502H, LA:GA=25:75, Mw=5000) in 2.5ml of dichloromethane to make an oil phase, and dissolve 10mg of exenatide in 0.05ml of double distilled water (containing 10mg of gelatin) to form For the inner water phase, add it to the above oil phase, ultrasonic emulsification, and form W1 / O colostrum, put 50ml of 1% PVA solution in a stirring container, and quickly add the colostrum to the outer water phase under high-speed stirring (1200rpm) After three minutes, reduce the rotation speed to 400rpm, add 0.5% polyvinyl alcohol solution, stir at room temperature for 4 hours, centrifuge and wash the microspheres after hardening, and freeze-dry. The encapsulation efficiency of the exenatide microspheres was 85%, and the particle size was less than 90 μm.

Embodiment 3

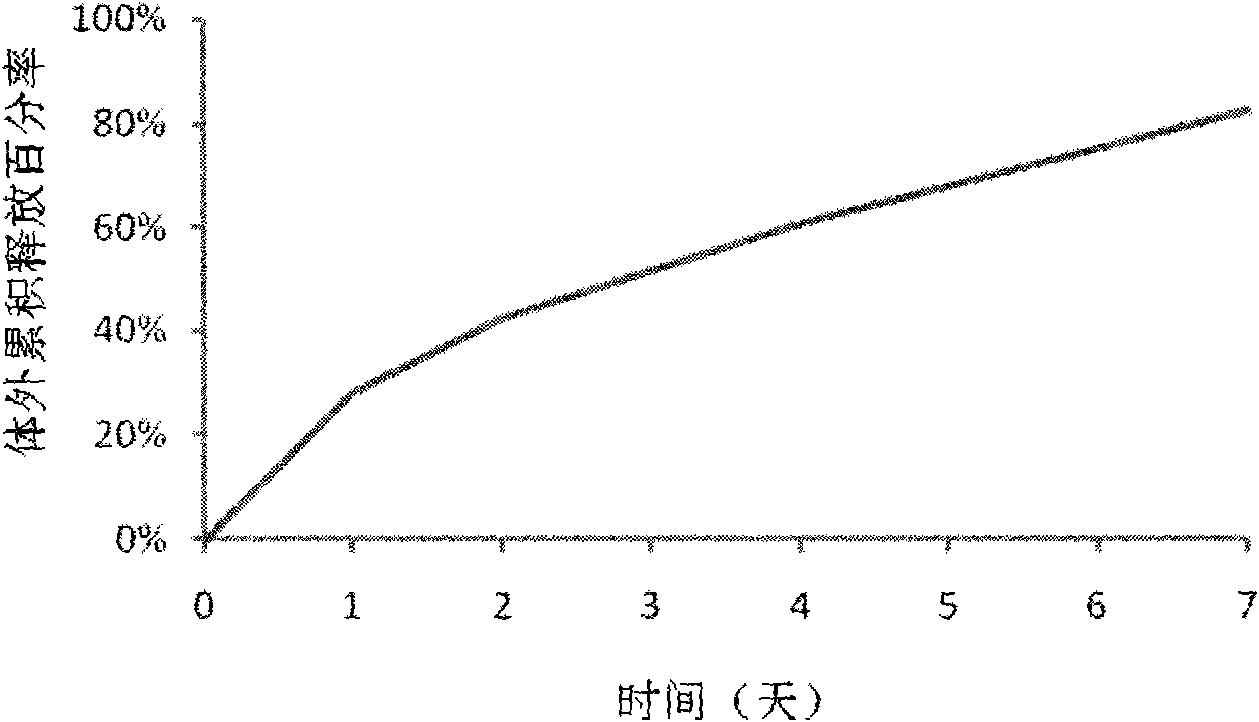

[0081] Example 3 Preparation of Exenatide Sustained-release Microspheres by W1 / O / W2 Solvent Evaporation

[0082] Dissolve 2000mg of PLGA (RG502H, LA:GA=75:25, Mw=20000) in 5.0ml of dichloromethane to make an oil phase, and dissolve 30mg of exenatide in 0.05ml of double distilled water (containing 15mg of gelatin) to form For the inner water phase, add it to the above-mentioned oil phase, ultrasonic emulsification, and form W1 / O colostrum, put 50ml of 3% PVA solution in a stirring container, and quickly add the colostrum to the outer water phase under high-speed stirring (1200rpm) After three minutes, reduce the rotation speed to 400rpm, add 1% polyvinyl alcohol solution, stir at room temperature for 4 hours, centrifuge and wash the microspheres after hardening, and freeze-dry. The encapsulation efficiency of the exenatide microspheres was 97%, and the particle size was less than 120 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com