Method for preparing adsorbent by modifying attapulgite clay

A technology of attapulgite clay and adsorbent, which is applied in the field of adsorbent preparation, can solve the problem of decolorization of wastewater that cannot contain dyes, etc., and achieves the effects of reduced production cost, low preparation cost and good decolorization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

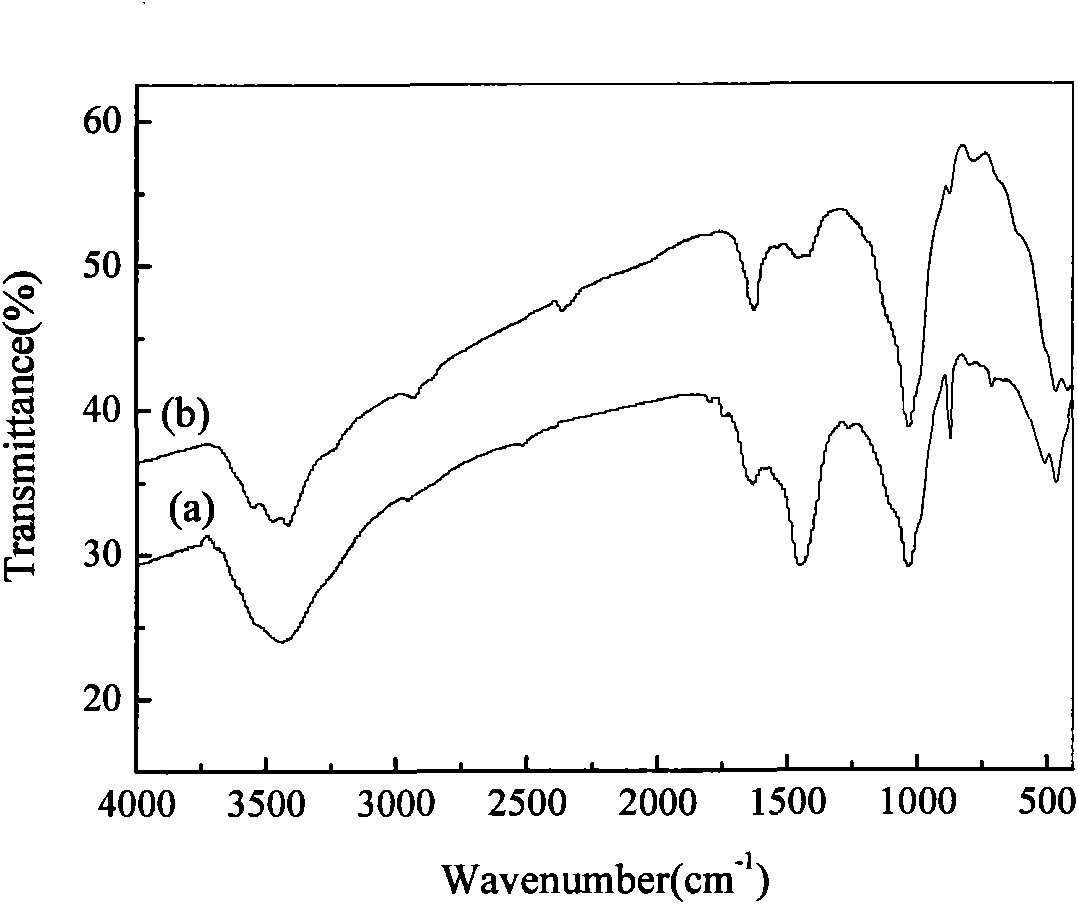

Method used

Image

Examples

Embodiment 1

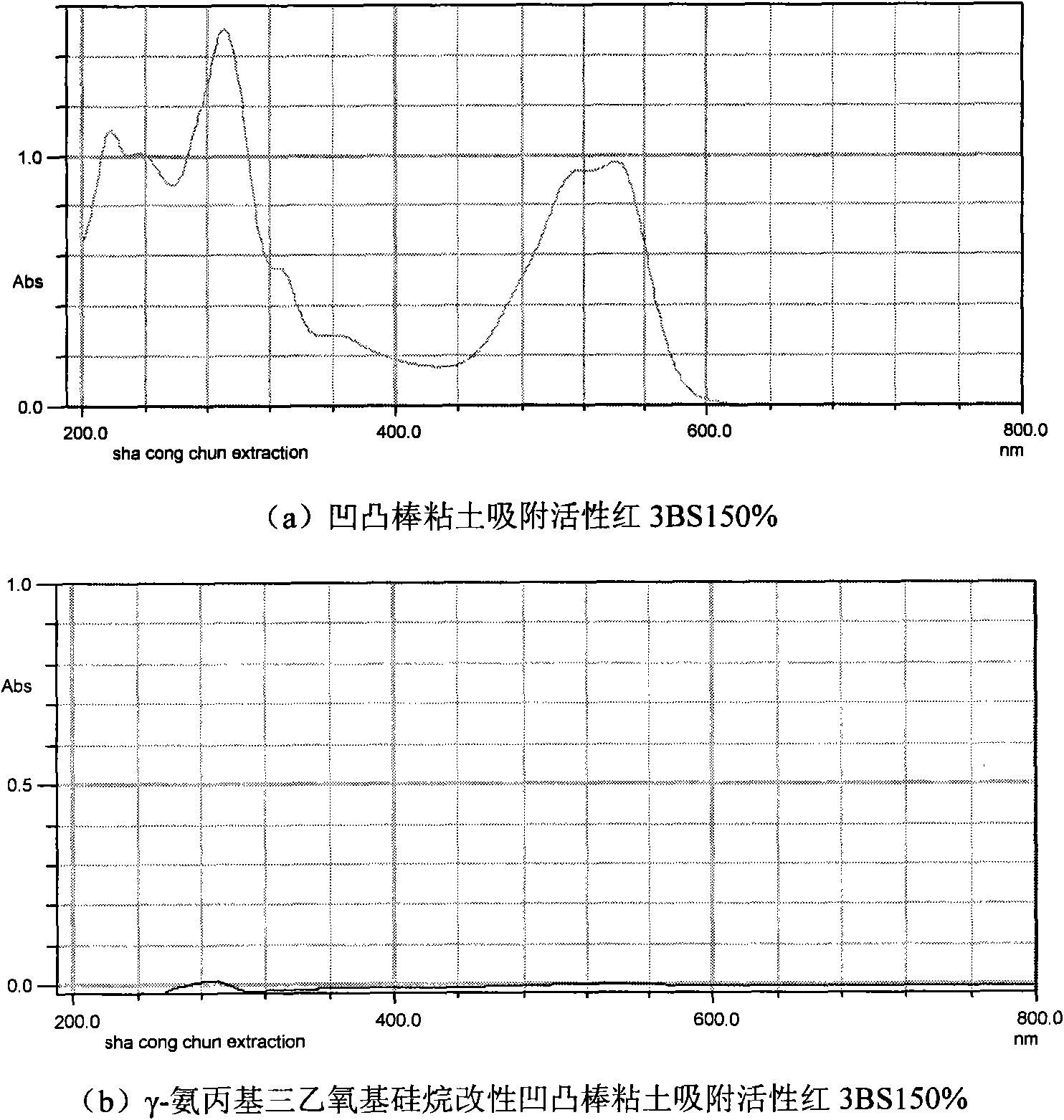

[0019] Add 3.0 grams of attapulgite clay to 50.0 mL of toluene, adjust the temperature to 30 °C, slowly add 1.5 ml of γ-aminopropyltrimethoxysilane during stirring, and react for 2 hours; filter, wash, dry and pulverize the reaction product over 200 mesh sieve to obtain a γ-aminopropyltriethoxysilane coupling agent-modified adsorbent. 0.3 g of the adsorbent was decolorized with reactive red 3BS150% dye wastewater, and the concentration was 100 mg / L reactive red 3BS150% dye 50ml, oscillating at a constant temperature in a water bath at 20°C for 30 minutes, centrifuging at 3000r / min for 10 minutes, separating solid-liquid two-phase, supernatant The decolorization effect of the liquid is obvious, and the decolorization rate of the active red is 88.12%.

Embodiment 2

[0021] Add 4.5 grams of attapulgite clay to 100.0 mL of toluene, adjust the temperature to 45 °C, slowly add 3.0 ml of γ-aminopropyltriethoxysilane during stirring, and react for 3 hours; filter, wash, dry and pulverize the reaction product 200 mesh sieve to obtain the adsorbent modified by γ-aminopropyltriethoxysilane coupling agent. 0.3 g of the adsorbent was decolorized with reactive red 3BS150% dye wastewater, and the concentration was 100 mg / L reactive red 3BS150% dye 50ml, oscillating at a constant temperature in a water bath at 20°C for 30 minutes, centrifuging at 3000r / min for 10 minutes, separating solid-liquid two-phase, supernatant The decolorization effect of the liquid is obvious, and the decolorization rate of the active red is 98.43%.

Embodiment 3

[0023] Add 6.0 grams of attapulgite clay to 150.0 mL of toluene, adjust the temperature to 60 ° C, slowly add 4.5 ml of N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane during stirring, and react for 4 hours; The reaction product is filtered, washed, dried, and crushed through a 200-mesh sieve to obtain a γ-aminopropyltriethoxysilane coupling agent-modified adsorbent. 0.3 g of the adsorbent was decolorized with reactive red 3BS150% dye wastewater, and the concentration was 100 mg / L reactive red 3BS150% dye 50ml, oscillating at a constant temperature in a water bath at 20°C for 30 minutes, centrifuging at 3000r / min for 10 minutes, separating solid-liquid two-phase, supernatant The decolorization effect of the liquid is obvious, and the decolorization rate of the active red is 99.73%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com