Method for removing pigment in spinosad fermented liquid

A technology of spinosyn and fermentation liquid, which is applied in the direction of separation methods, chemical instruments and methods, biocides, etc., can solve the problems that are not conducive to process scale-up production, cannot achieve complete adsorption, and the filtrate is turbid, and achieve fast adsorption speed, Strong adsorption capacity and the effect of improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Medium formula: carbon source - glucose nitrogen source - cottonseed meal

[0038] Take 3L of spinosad fermentation broth, centrifuge at 4000r / min for 30min to obtain mycelia, soak in 3L of acetone overnight, centrifuge again at 4000r / min for 30min to get the supernatant, and obtain the pretreated spinosad fermentation broth.

[0039] Take 500ml of the pretreated spinosad fermentation broth, the unit is 823ug / ml, and the pH is 6.0, select a glass chromatography column with a height of 20cm and a diameter of 3cm, fill it with acidic alumina about 10cm evenly, and leaching with acetone A certain amount of deionized water was added to the solution to prepare a 9:1 acetone aqueous solution and then loaded on the column, and the flow rate was controlled to be 15ml / min. After passing 500ml of the leaching solution through the column, continue to use 500ml of 9:1 acetone water to drain the column. Wash down the spinosad on and collect all eluate.

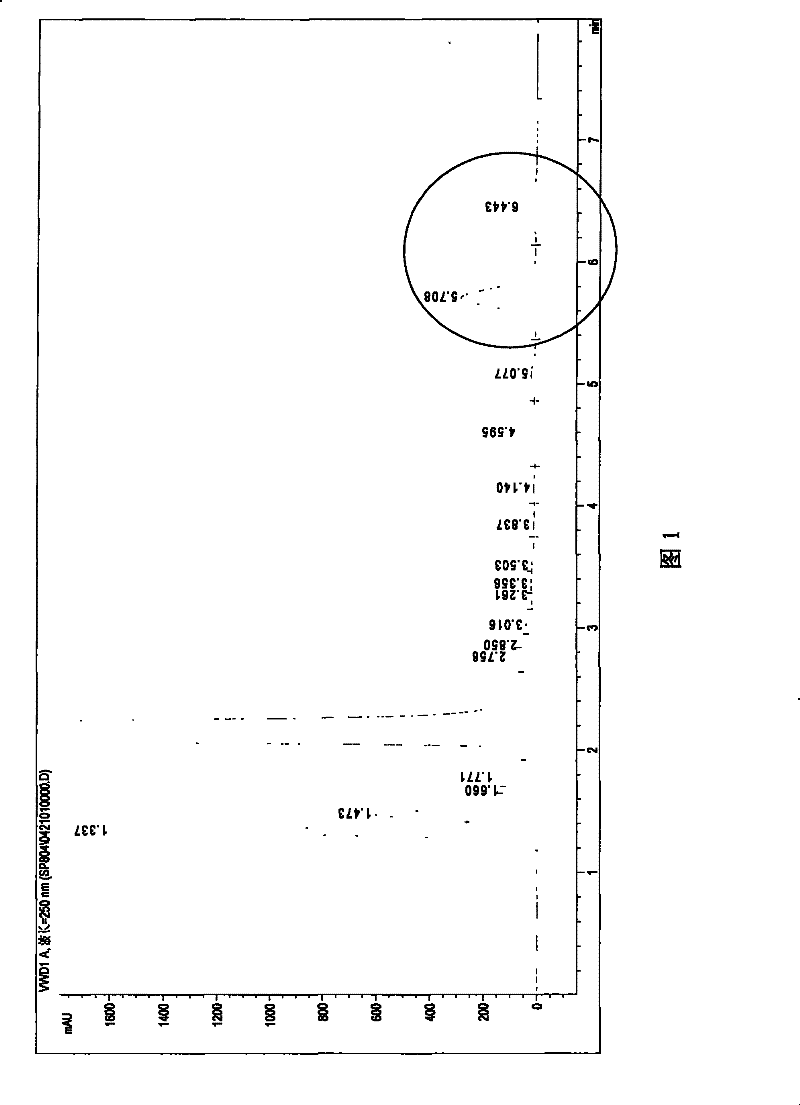

[0040] It was found that th...

Embodiment 2

[0042] Medium formula: carbon source - glucose nitrogen source - cottonseed meal

[0043] Take 3L of spinosad fermentation broth, centrifuge at 4000r / min for 30min to obtain mycelia, soak in 3L of acetone overnight, centrifuge again at 4000r / min for 30min to get the supernatant, and obtain the pretreated spinosad fermentation broth.

[0044] Take 500ml of the pretreated spinosad fermentation broth, the unit is 823ug / ml, the pH is 6.4, select a glass chromatography column with a height of 20cm and a diameter of 3cm, fill it with acidic alumina about 10cm evenly, and leaching with acetone The liquid was directly loaded on the column, and the flow rate was controlled at 15ml / min. After passing through the column, the spinosad on the column was continued to be washed with acetone, and all eluents were collected.

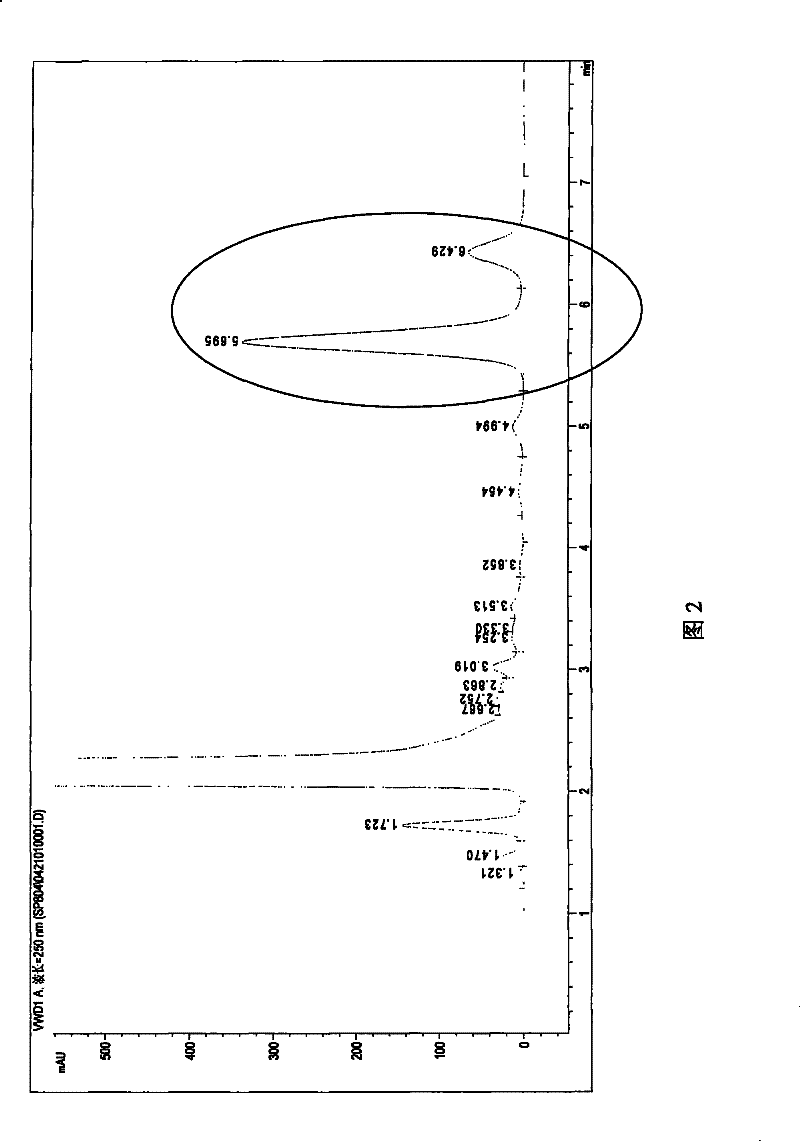

[0045]It was found that the eluate had become clear, almost colorless, most of the pigments had been removed, the purity was increased from 19.4% to 66%, and the yield w...

Embodiment 3

[0047] Medium formula: carbon source - glucose nitrogen source - cottonseed meal

[0048] Take 3L of spinosad fermentation broth, centrifuge at 4000r / min for 30min to obtain mycelia, soak in 3L of acetone overnight, centrifuge again at 4000r / min for 30min to get the supernatant, and obtain the pretreated spinosad fermentation broth.

[0049] Get pretreated spinosad fermented liquid 500ml, unit is 823ug / ml, and pH is 6.5, selects a height to be 20cm, the glass chromatography column of diameter 3cm, evenly fills in about 10cm of acid alumina, is made into 4: 1 of the acetone aqueous solution was put on the column, and the flow rate was controlled at 15ml / min. After passing 500ml of the leaching liquid through the column, continue to wash off the spinosad on the column with 500ml of 4:1 acetone water, and collect all the eluted liquid.

[0050] It was found that the eluate had become clear, had almost no color, removed most of the pigments, and the purity was increased to 68% fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com