Fe-X-N grain refiner and preparation method thereof

A technology of grain refiner, fe35, which is applied in the field of metal materials, can solve problems such as easy segregation, and achieve the effects of simple preparation, grain refinement, and obvious refinement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

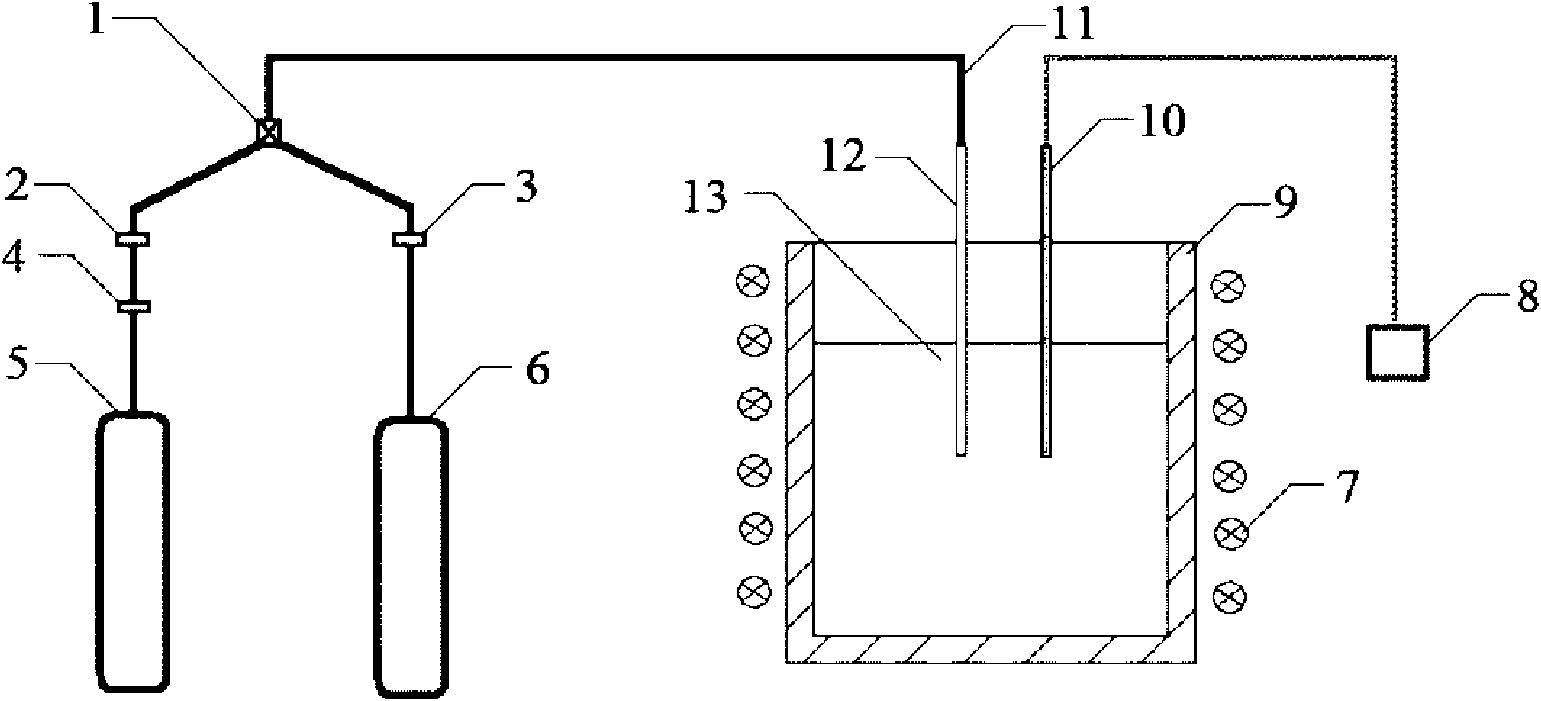

Method used

Image

Examples

Embodiment 1

[0025] Step 1, mixing iron with metals Ti, V and Nb, melting the mixture in a vacuum intermediate frequency induction furnace to obtain a melt,

[0026] For the mixing, the parts by weight of iron are 99.4 parts, the parts by weight of metal Ti are 0.3 parts, the parts by weight of metal V are 0.1 parts, and the parts by weight of metal Nb are 0.1 parts;

[0027] Step 2, when the temperature of the melt is 1650°C, nitrogen gas is introduced, and when the nitrogen partial pressure around the melt reaches 0.01Mpa, nitrogen gas is blown into the melt for 3 hours;

[0028] Step 3, stop blowing nitrogen gas, cut off the power, and obtain the Fe-X-N grain refiner.

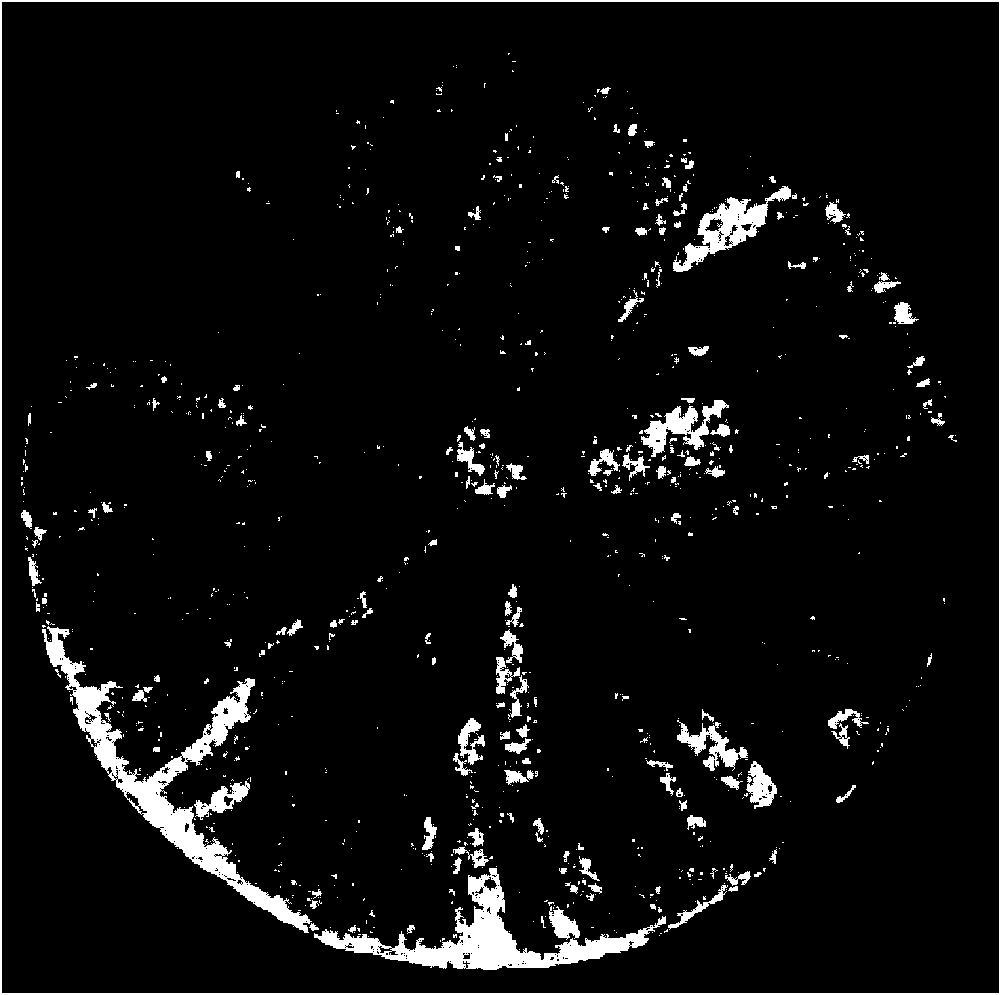

[0029] The Fe-X-N grain refiner obtained in this example has the following components and mass percentages: 99.4% Fe, 0.3% Ti, 0.1% V, 0.1% Nb, and 0.1% N. The XN density in the obtained grain refiner is 10 8 piece / mm 3 ; The particle size of XN in the obtained grain refiner is mainly concentrated in 0.5-5 μm.

[003...

Embodiment 2

[0032] Step 1, mixing iron with metals Ti, V and Nb, melting the mixture in a vacuum intermediate frequency induction furnace to obtain a melt,

[0033] In the mixing, the parts by weight of iron are 67.5 parts, the parts by weight of metal Ti are 10 parts, the parts by weight of metal V are 5 parts, and the parts by weight of metal Nb are 10 parts;

[0034] Step 2, when the temperature of the melt is 1600°C, nitrogen gas is introduced, and when the nitrogen partial pressure around the melt reaches 0.05Mpa, nitrogen gas is blown into the melt for 1.5 hours;

[0035] Step 3, stop blowing nitrogen gas, cut off the power, and obtain the Fe-X-N grain refiner.

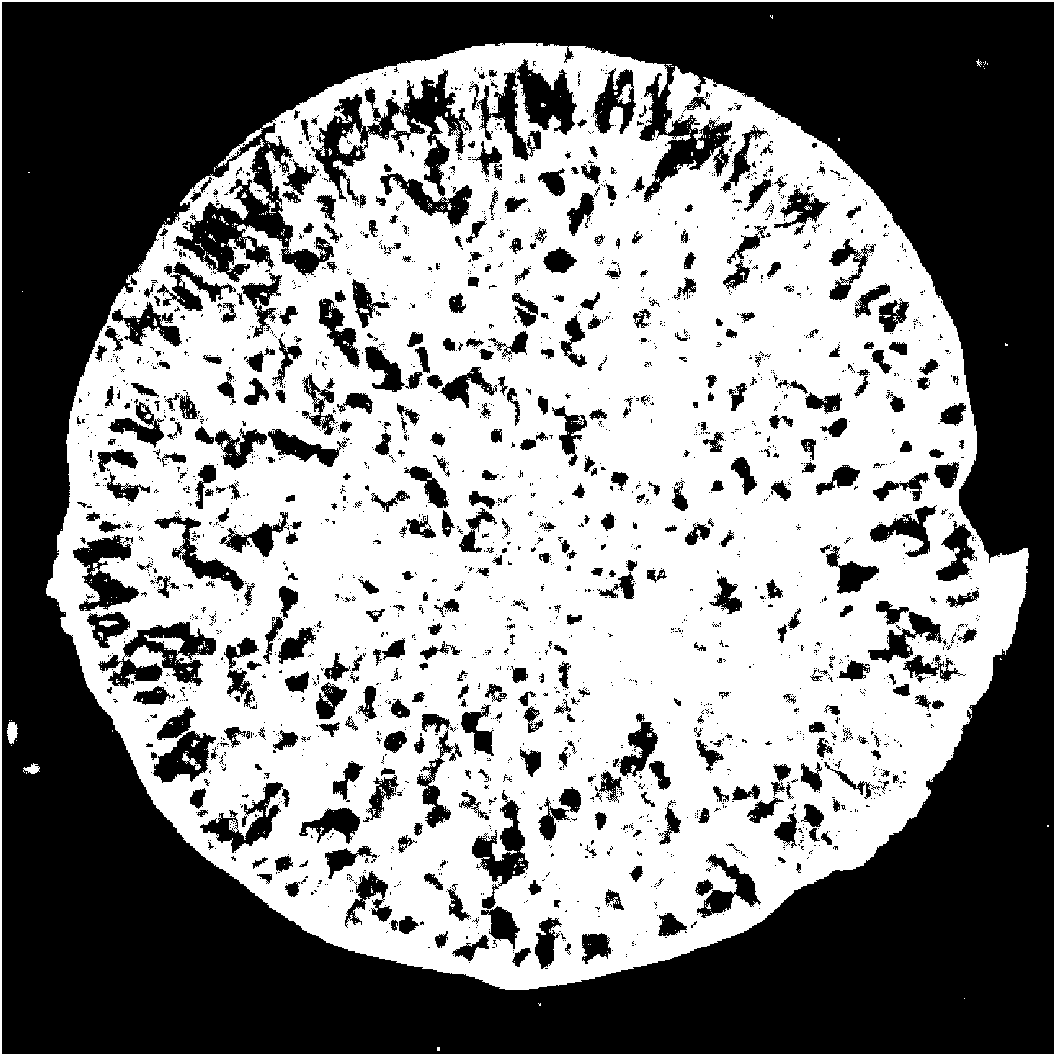

[0036] The Fe-X-N grain refiner obtained in this example has the following components and mass percentages: 67.5% Fe, 10% Ti, 5% V, 10% Nb, and 7.5% N. The XN density in the obtained grain refiner is 10 4 piece / mm 3 ; The particle size of XN in the obtained grain refiner is mainly concentrated in 0.5-5 μm.

Embodiment 3

[0038] Step 1, mix iron with metal Ti and Nb, and melt the mixture in a vacuum intermediate frequency induction furnace to obtain a melt

[0039] Said mixing, the parts by weight of iron is 35 parts, the parts by weight of metal Ti is 25 parts, and the parts by weight of metal Nb is 25 parts;

[0040] Step 2, when the temperature of the melt is 1550°C, nitrogen gas is introduced, and when the nitrogen partial pressure around the melt reaches 0.01Mpa, nitrogen gas is blown into the melt for 10s;

[0041] Step 3, stop blowing nitrogen gas, cut off the power, and obtain the Fe-X-N grain refiner.

[0042] The Fe-X-N grain refiner obtained in this example has the following components and mass percentages: 35% Fe, 25% Ti, 25% Nb, and 15% N. The XN density in the obtained grain refiner is 10 7 piece / mm 3 ; The particle size of XN in the obtained grain refiner is mainly concentrated in 0.5-5 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com