Photomask blank and photomask

A technology of photomasks and light-shielding materials, which is applied in the direction of photosensitive materials used in photomechanical equipment, optics, and photographic plate-making processes on patterned surfaces. It can solve problems such as inability to exert sensitivity and achieve excellent linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

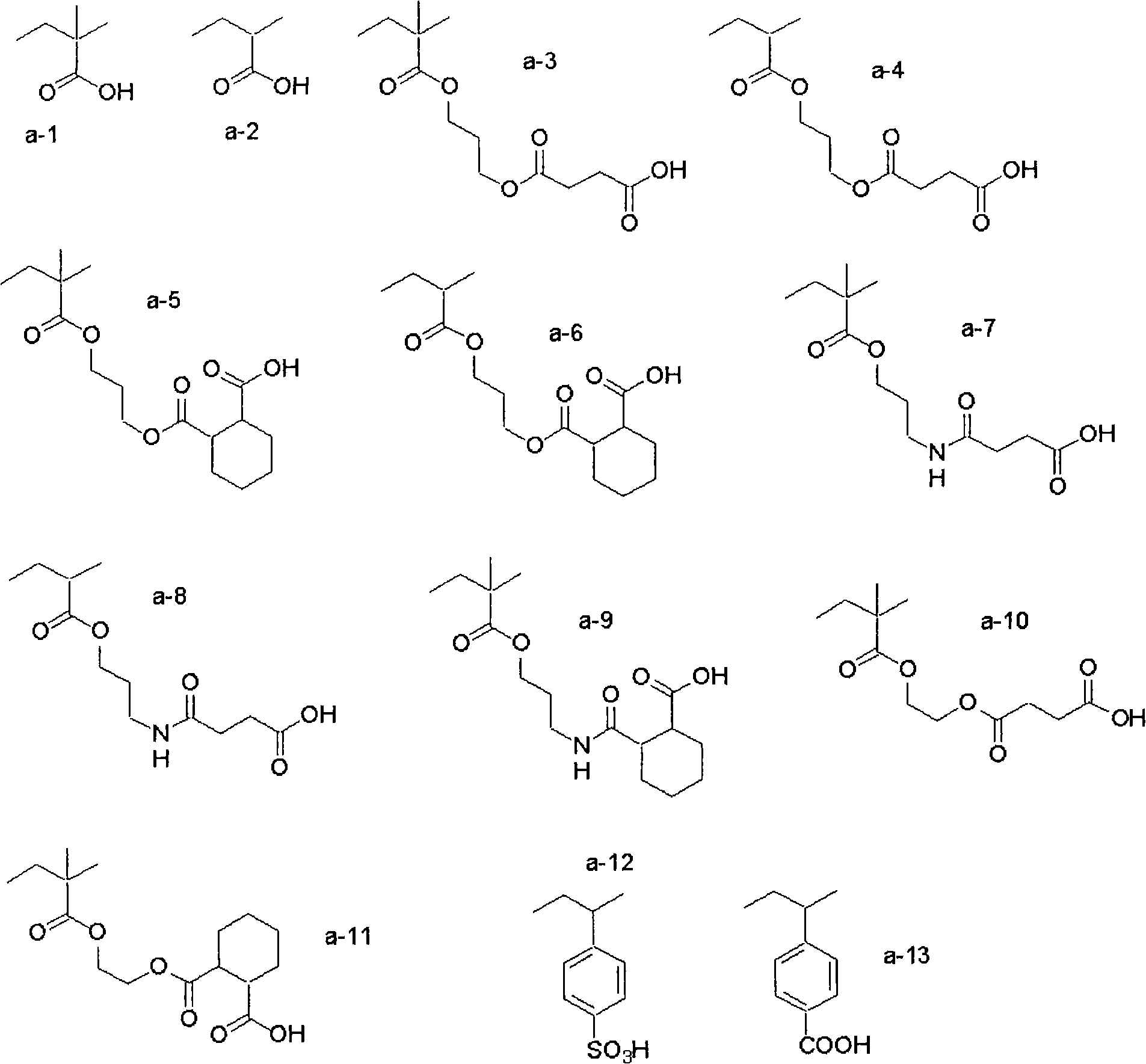

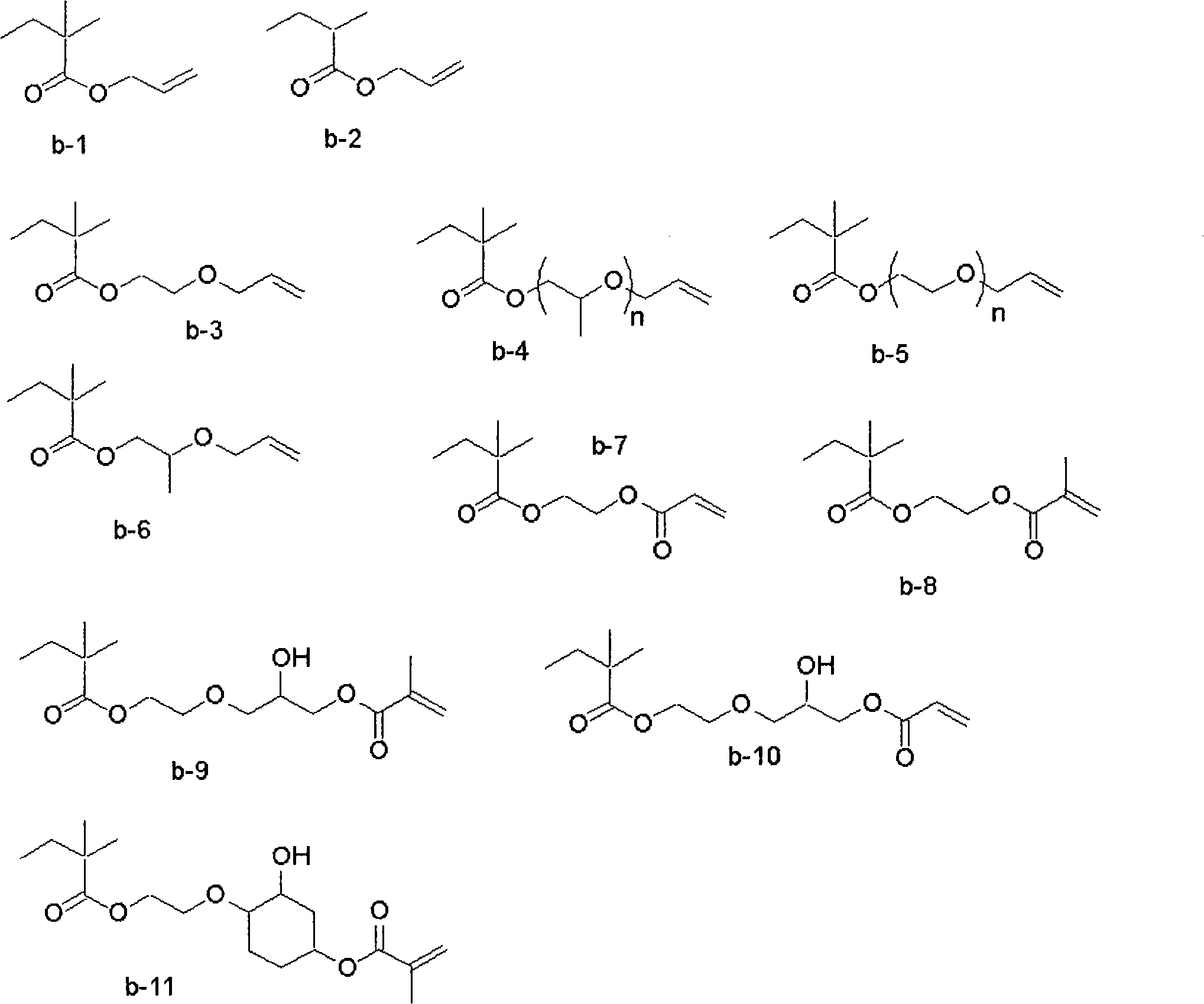

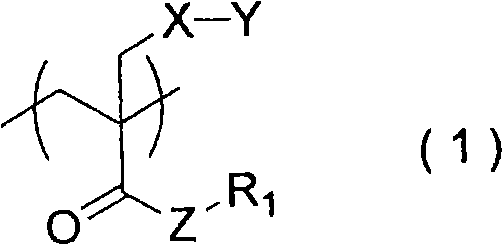

Method used

Image

Examples

Embodiment 1~15、 comparative example 1~5

[0328] 1. Production of photomask

[0329] (Formation of photosensitive layer)

[0330] On a glass substrate (10cm×10cm), the dry coating mass is 1.4g / m 2 The high-sensitivity photopolymerizable composition P-1 of the following composition was applied by the method, and it was made to dry at 100 degreeC for 1 minute, and the photosensitive layer was formed.

[0331]

[0332] · Carbon black dispersion 16.0 parts by mass

[0333] (CDP-K8, manufactured by Toyo Kasei Co., Ltd., 50% by mass propylene glycol monomethyl ether acetate solution)

[0334] ・Ethylenically unsaturated compound (A-1) (compound of the following structure) 4.2 parts by mass

[0335] ・Linear organic polymer (B-1) (polymer binder with the following structure, weight average molecular weight: 50,000) 3.6 parts by mass

[0336] ・Sensitizing dye (C-1) (compound of the following structure) 0.21 parts by mass

[0337] ・Photopolymerization initiator (D-1) (compound of the following structure) 0.81 parts by mas...

Embodiment 16~30、 comparative example 6~10

[0364] In Examples 1 to 15 and Comparative Examples 1 to 5, the high-sensitivity photopolymerizable composition P-1 for forming the photosensitive layer was changed to the high-sensitivity photopolymerizable composition P-2 of the following composition, except Except, operate in the same manner as Examples 1-15 and Comparative Examples 1-5, obtain the photomask plates (6)-(30) of Examples 16-30 and the photomask plates (C6) of Comparative Examples 6-10 )~(C10).

[0365]

[0366] 16 parts by mass of carbon black dispersion

[0367] (CDP-K8, manufactured by Toyo Kasei Co., Ltd., 50% propylene glycol monomethyl acetate solution)

[0368] ・Ethylenically unsaturated compound (A-1) (compound of the above structure) 4.2 parts by mass

[0369] ・Linear organic polymer (B-1) (polymer binder with the above structure, weight average molecular weight: 50,000) 3.6 parts by mass

[0370] ・Sensitizing pigment (C-1) (compound of the above structure) 0.21 parts by mass

[0371] ・Photopoly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Saponification degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com