Microwave reaction synthesis method for endogenous metal matrix composite material

A composite material and microwave reaction technology, applied in the field of microwave reaction synthesis method, to achieve the effect of purifying the matrix, shortening the preparation cycle, and refining the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Al-TiO 2 -B reaction system

[0028] (1) Prepare the reaction sample with Al, TiO 2 , B powder according to the set reinforcement (TiB 2 and Al 2 o 3 ) volume fraction (such as 30%), by chemical reaction formula: 4Al+3TiO 2 +6B→3TiB 2 +2Al 2 o 3 By stoichiometric calculation, the reaction formula satisfy the thermodynamic conditions of the reaction. Through calculation, 15.43g of Al powder, TiO 2 Powder 4.57g and B powder 0.57g. Then put it into a ball mill jar, ball mill and mix at a ball-to-powder ratio of 5:1 at a speed of 300 p.r.m, and then extrude it into a billet with a pressure of 120 MPa to make a compact sample;

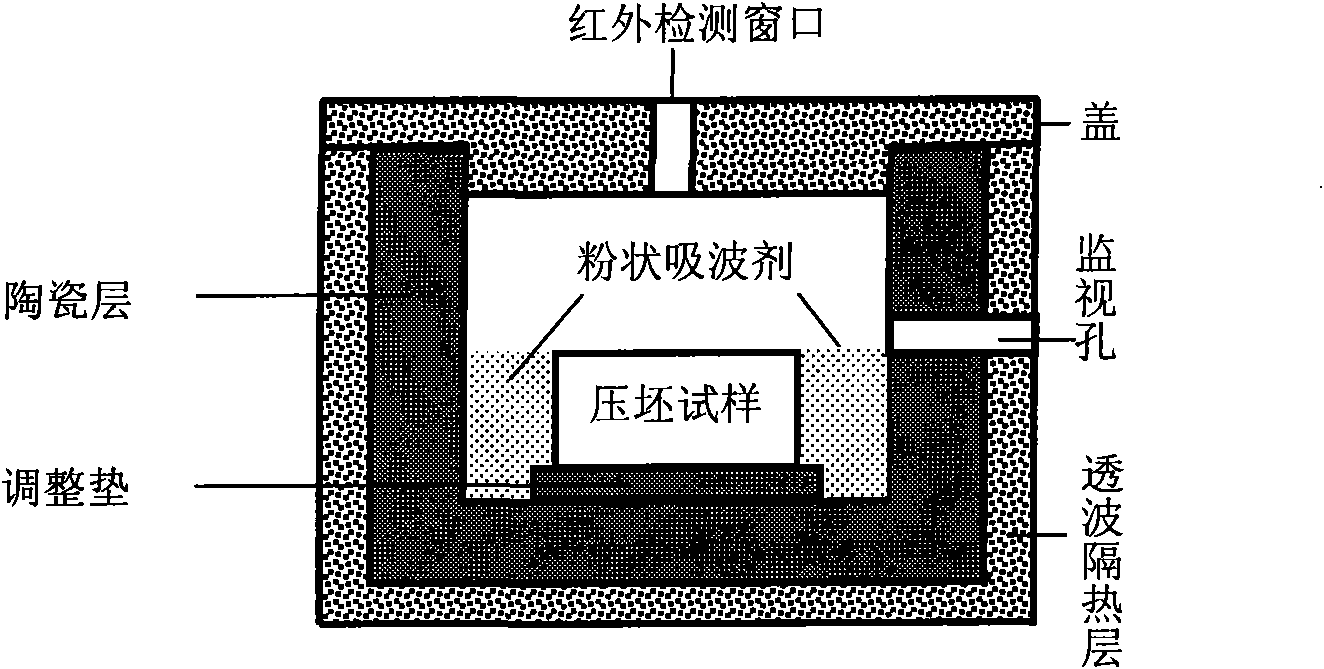

[0029] (2) Sample loading Put the compacted sample into the reaction device, see figure 1 ;Pay attention to the following points when loading samples: 1) Exposing the top of the compact sample to ensure the accuracy of infrared temperature measurement on the top of the sample; 2) SiC wave absorbing agent should not block the m...

Embodiment 2

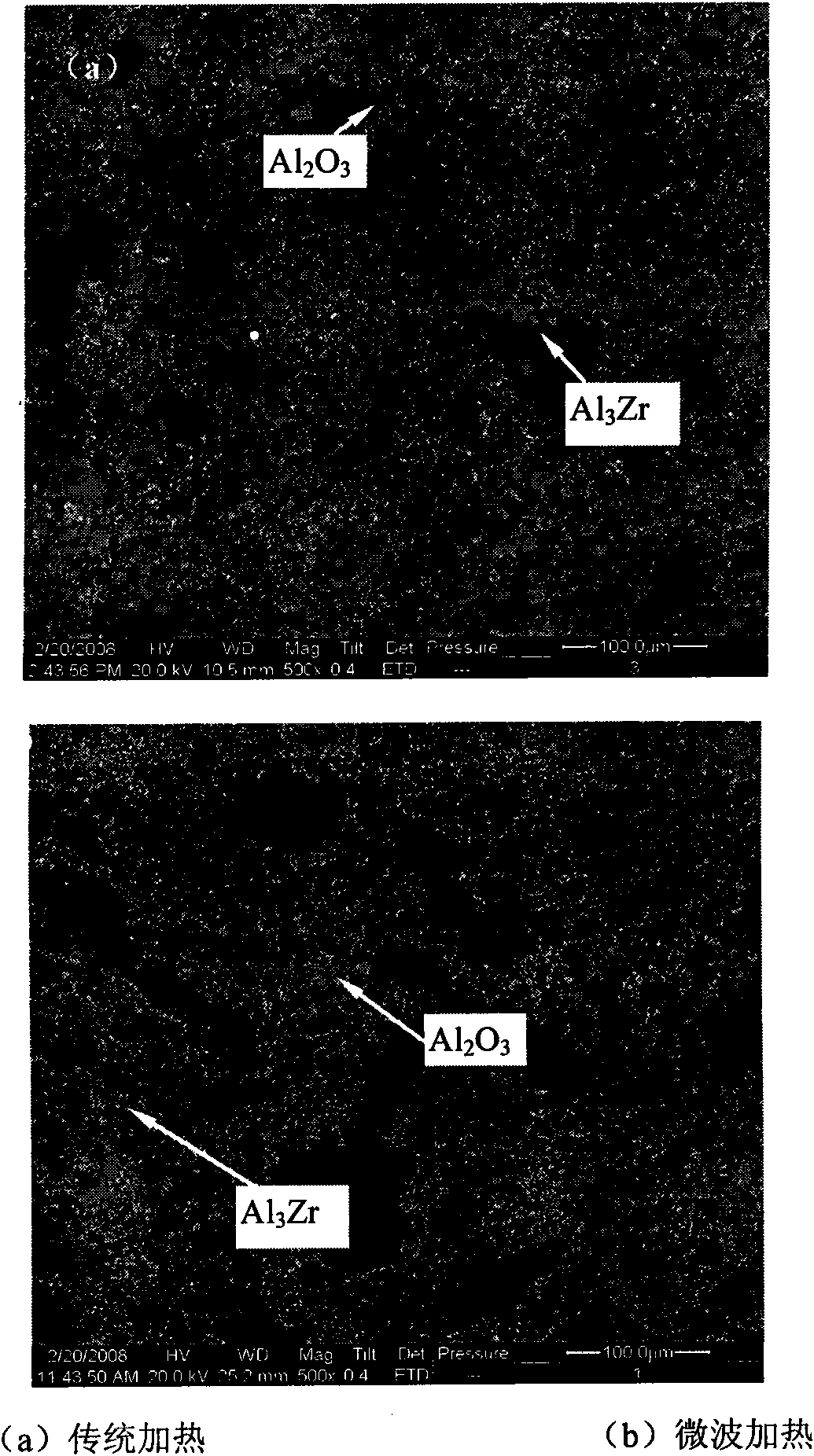

[0035] Example 2: Al-ZrO 2 system

[0036] (1) Prepare the reaction sample by Al, ZrO 2 powder according to the set reinforcement (Al 3 Zr and Al 2 o 3 ) volume fraction (such as 30%), by chemical reaction formula: 13Al+3ZrO 2 →3Al 3 Zr+2Al 2 o 3 By stoichiometric calculation, the reaction formula satisfy the thermodynamic conditions of the reaction. Through calculation, the reaction sample of 20g needs Al powder 16.1g and ZrO 2 Powder 3.9g, then put it in the ball mill jar, with the ball powder ratio of 5:1, 300p.r.m rotating speed ball mill and mix, and then extrude into a billet with a pressure of 120MPa to make a compact sample;

[0037] (2) Sample loading Put the compacted sample into the reaction device, see figure 1 ;Pay attention to the following points when loading samples: 1) Exposing the top of the compact sample to ensure the accuracy of infrared temperature measurement on the top of the sample; 2) SiC wave absorbing agent should not block the monitorin...

Embodiment 3

[0043] Example 3: Al-Ni 2 o 3 reaction system

[0044] (1) Prepare the reaction sample with Al, Ni 2 o 3 powder according to the set reinforcement (Ni 2 al 3 and Al 2 o 3 ) volume fraction (such as 20%), by chemical reaction formula: 5Al+Ni 2 o 3 →Ni 2 al 3 +Al 2 o 3 By stoichiometric calculation, the reaction formula satisfy the thermodynamic conditions of the reaction. Through calculation, 13.26g of Al powder is needed for 20g of reaction sample, Ni 2 o 3 Powder 1.74g, then put it in the ball mill jar, with the ball powder ratio of 5:1, 300p.r.m rotating speed ball mill and mix, then extrude into a billet with a pressure of 120MPa to make a compact sample;

[0045] (2) Sample loading Put the compacted sample into the reaction device (see figure 1 ); pay attention to the following points when loading samples: 1) expose the top of the compacted sample to ensure the accuracy of infrared temperature measurement on the top of the sample; 2) SiC wave absorbing ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com