Hybrid fabric grid made from carbon fiber and basalt fiber

A technology of basalt fiber and carbon fiber, applied in the direction of carbon fiber, fiber treatment, building construction, etc., can solve the problems of poor structural ductility, uneven distribution, poor impact resistance, etc., and achieve improved tensile strength, impact resistance and ductility The effect of performance, clear bearing direction and good crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

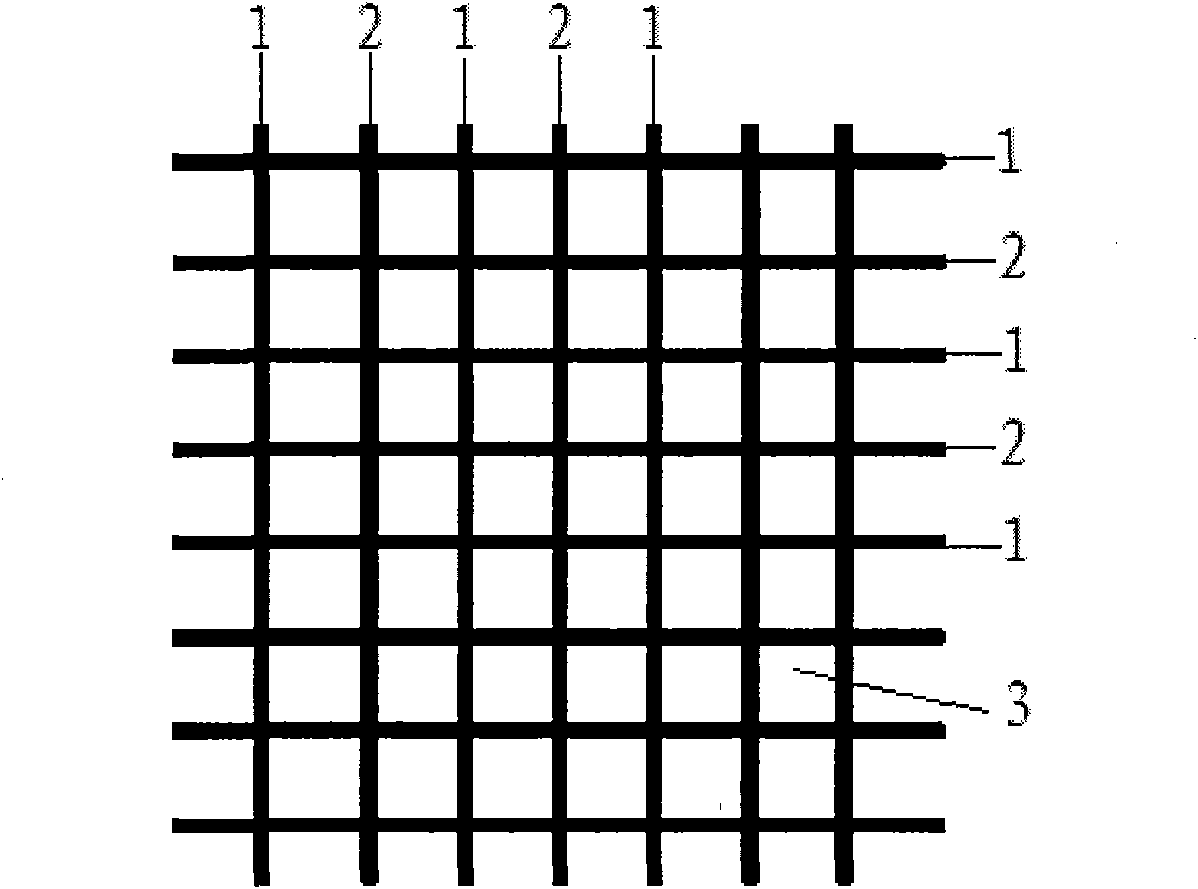

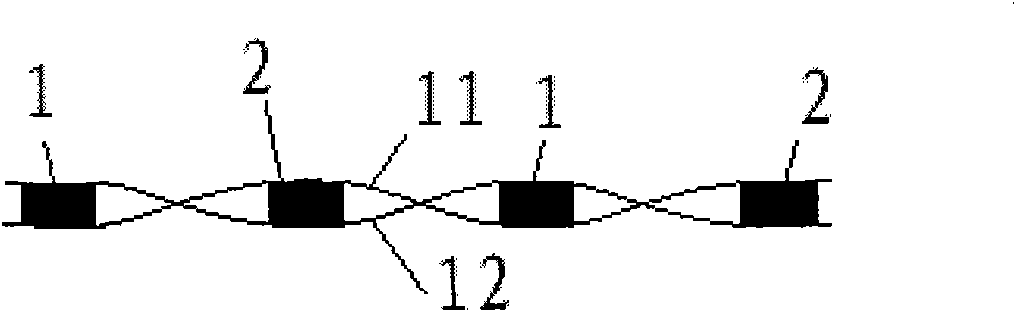

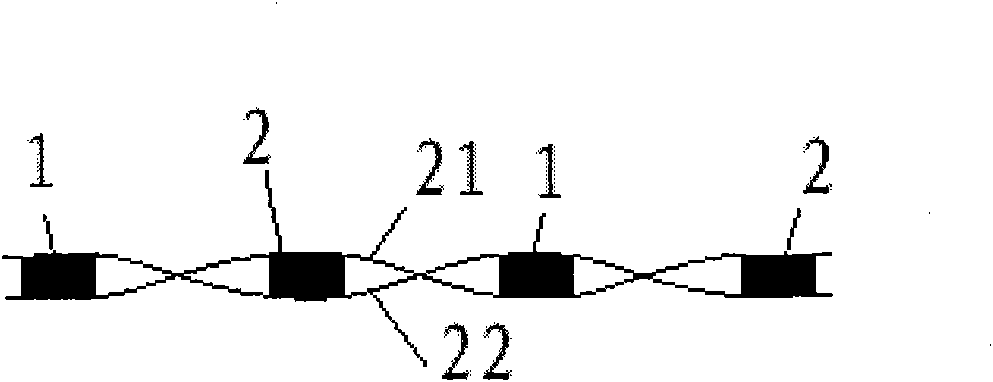

[0021] This example figure 1 As shown, basalt fibers 2 and carbon fibers 1 are interlaced to form a grid. In order to improve its strength and compactness, a polyurethane resin layer 3 is coated on the grid, and the amount of resin is 60g / m 2 ;Such as figure 2 Each strand of carbon fiber 1 shown is divided into two bundles 11 and 12, and the two cross after passing through carbon fiber 1 or basalt fiber 2, interlaced with carbon fiber 1 or basalt fiber 2, and between carbon fiber 1 and basalt fiber 2 or carbon fiber 1 and carbon fiber 1 or Nodes are formed at the intersection of basalt fiber 2 and basalt fiber 2, such as image 3 Each strand of basalt fiber 2 shown is divided into two bundles 21 and 22, and the two are intersected after passing through carbon fiber 1 or basalt fiber 2, interlaced with carbon fiber 1 or basalt fiber 2, and between carbon fiber 1 and basalt fiber 2 or carbon fiber 1 and carbon fiber 1 Or nodes are formed at intersections of basalt fibers 2 an...

Embodiment 2

[0023] This example figure 1 As shown, basalt fiber warp strands 2 and carbon fiber weft strands 1 are staggered to form a grid. In order to improve its strength and compactness, epoxy resin layer 3 is coated on the grid, and the amount of resin is 40g / m 2 ;Such as figure 2 Each strand of carbon fiber 1 shown is divided into two bundles 11 and 12, and the two cross after passing through carbon fiber 1 or basalt fiber 2, interlaced with carbon fiber 1 or basalt fiber 2, and between carbon fiber 1 and basalt fiber 2 or carbon fiber 1 and carbon fiber 1 or Nodes are formed at the intersection of basalt fiber 2 and basalt fiber 2, such as image 3 Each strand of basalt fiber 2 shown is divided into two bundles 21 and 22, and the two are intersected after passing through carbon fiber 1 or basalt fiber 2, interlaced with carbon fiber 1 or basalt fiber 2, and between carbon fiber 1 and basalt fiber 2 or carbon fiber 1 and carbon fiber 1 Or nodes are formed at intersections of basa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com