Method for manufacturing moisture-free granular flavoring

A production method and seasoning technology, which are applied in the directions of food preparation, application, food science, etc., can solve the problem of not easy to absorb moisture, and achieve the effects of not easy to absorb moisture, no change in solubility, and preventing moisture absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

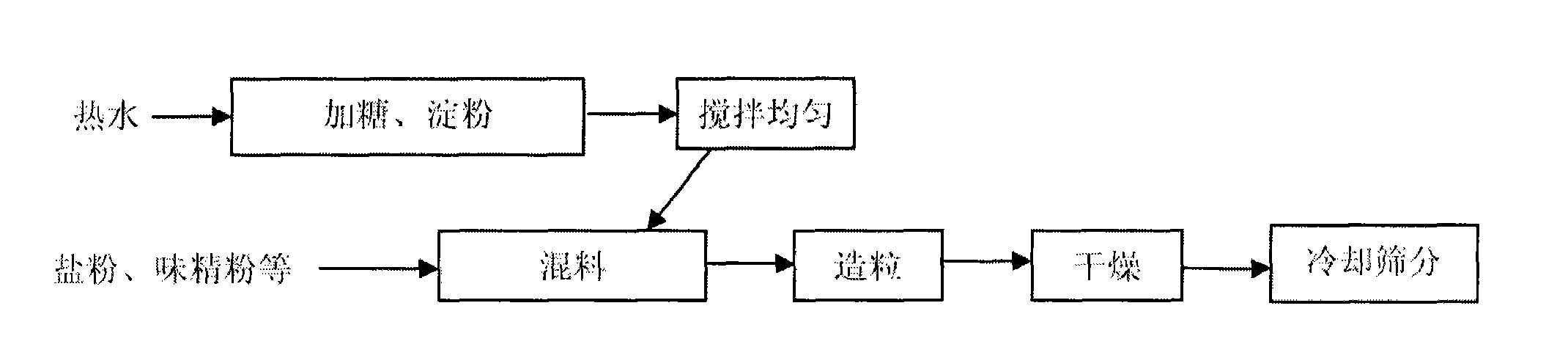

[0028] Embodiment 1-3: with the specific embodiment of chicken essence seasoning, in conjunction with Table 1 formula and figure 1 for further clarification.

[0029] formula:

[0030] Table 1 chicken essence granule seasoning embodiment formula

[0031] Ingredients name

Embodiment 1 formula

Embodiment 2 formula

Embodiment 3 formula

46kg

44kg

40kg

salt powder

35kg

37kg

37kg

White sugar

6kg

6kg

8kg

4.5kg

4.5kg

6.5kg

1kg

1kg

0kg

chicken powder

4kg

4kg

4kg

2kg

2kg

2kg

Nucleotide Disodium

1.5kg

1.5kg

1.5kg

total

100kg

100kg

100kg

Add water

4.5kg

4.5kg

4.5kg

[0032] Specific production steps

[0033] Use example 1-3 formula to make according to the following steps respectively:

[0034] 1. Prepa...

Embodiment 4-6

[0039] Embodiment 4-6: with the specific embodiment of pork bone granule seasoning, in conjunction with formula table 2 and figure 1 for further clarification.

[0040] formula:

[0041] Table 2 pork bone granule seasoning example recipe

[0042] Ingredients name

Embodiment 4 formula

Embodiment 5 formula

Embodiment 6 formula

44kg

40kg

40kg

salt powder

37kg

38kg

38kg

White sugar

6kg

8kg

8kg

3.8kg

5.8kg

5.8kg

1kg

0kg

0kg

Pork Noodles

3kg

3kg

3kg

lard

2kg

2kg

2kg

Concentrated Pork Bone Juice

1kg

1kg

1kg

Nucleotide Disodium

1.2kg

1.2kg

1.2kg

dark soy sauce

1kg

1kg

1kg

total

100kg

100kg

100kg

Add water

3.5kg

3.5kg

3.5kg

[0043] Specific production steps

[0044] Use exam...

Embodiment 7-9

[0050] Embodiment 7-9: with the specific embodiment of mushroom granule seasoning, in conjunction with formula table 3 and figure 1 for further clarification.

[0051] formula:

[0052] Table 3 Mushroom Granules Seasoning Example Recipe

[0053] Ingredients name

Embodiment 7 formula

Embodiment 8 formula

Embodiment 9 formula

44kg

46kg

42kg

salt powder

37kg

37kg

37kg

White sugar

6kg

6kg

8kg

5.5kg

3.5kg

5.5kg

2kg

2kg

1kg

mushroom powder

4kg

4kg

4kg

Nucleotide Disodium

1.5kg

1.5kg

1.5kg

total

100kg

100kg

100kg

Add water

5kg

5kg

5kg

[0054] Specific production steps

[0055] Use example 7-9 formula to make according to the following steps respectively:

[0056] 1. Preparation of the suspension: heat the soft water to boil, ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com