Method for co-producing cement, sulfuric acid and gypsum by using lead-zinc tailings and acid-leaching electrolytic manganese residues as main raw materials

A technology of electrolytic manganese slag, the main raw material, applied in chemical instruments and methods, calcium/strontium/barium sulfate, sulfur compounds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

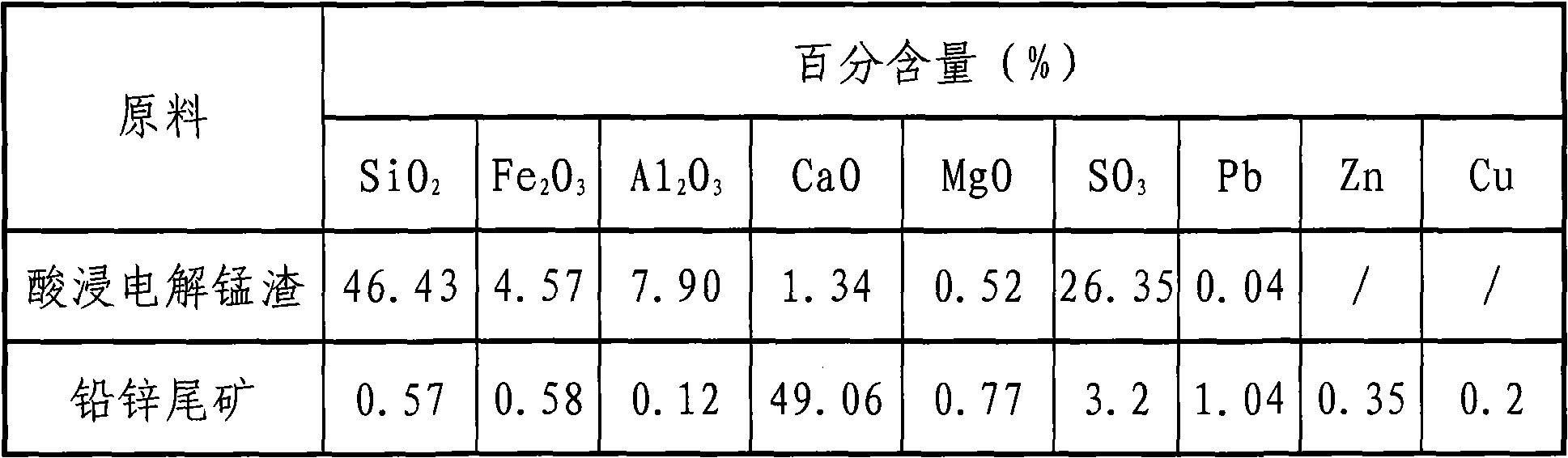

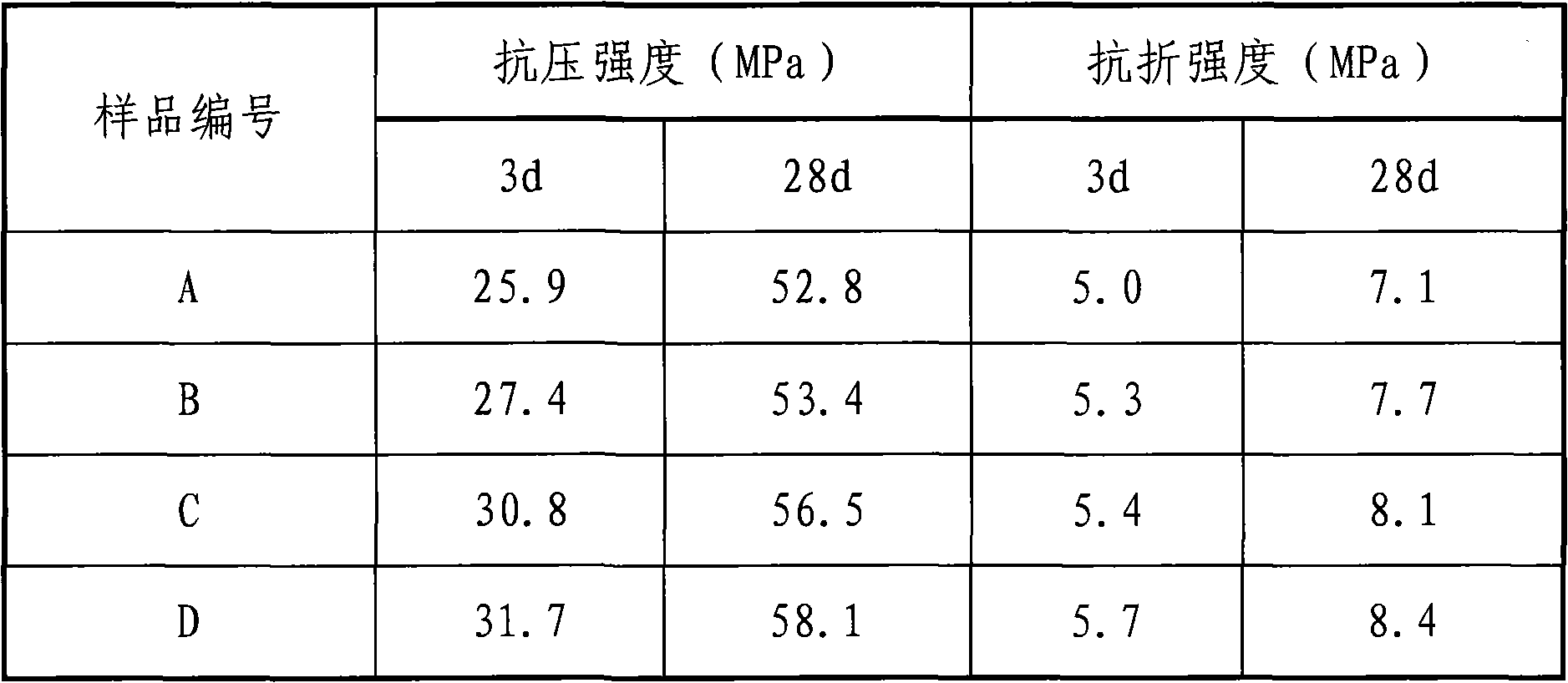

[0009] The main raw materials are Huayuan lead-zinc tailings and acid leaching electrolytic manganese slag, which are shown in Table 1, and the lead-zinc tailings, acid leaching electrolytic manganese slag, diaspore or bauxite, and iron powder are as shown in Table 2. After the ingredients reach the rate value in Table 3 (the ingredients of each batch of raw materials are different in production, the ratio of raw materials should be changed appropriately according to the change of ingredients, so as to meet the requirements of each rate value set), grind to 0.08mm sieve residue Less than 10%, the mixture is sent to the rotary kiln and calcined at 1390°C ± 50°C with the coal in the proportion in Table 2 as fuel, and the clinker obtained by quenching meets the requirements of 52.5 grade cement (results are shown in Table 4).

[0010] The kiln gas SO that will be produced 2 Sulfuric acid product (containing H 2 SO 4 ≥98%), each process is normally controlled according to the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com