A polyurethane-coated controlled-release fertilizer with improved mechanical properties and its preparation method and special coating material

A technology for controlled-release fertilizers and coating materials, applied in polyurea/polyurethane coatings, fertilizer mixtures, applications, etc., can solve the problems of poor water resistance of the film layer, problems with the stability of the film layer, etc., and achieve resistance to mechanical damage. The effect of improved properties, elasticity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

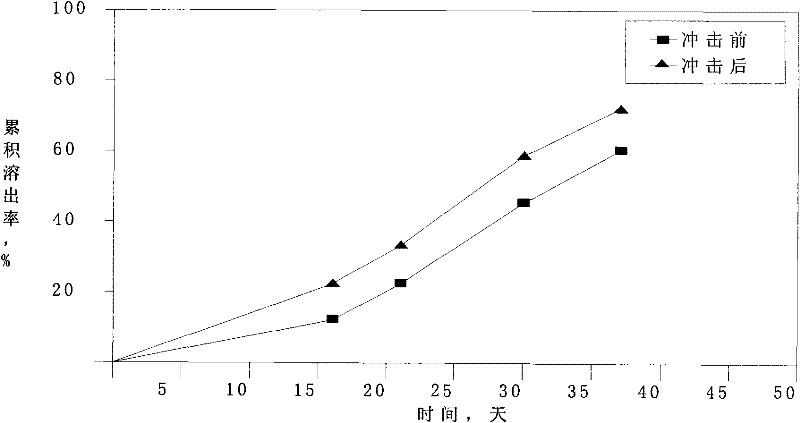

[0028] Example 1. Preparation of polyurethane coated fertilizer using MDI prepolymer

[0029] Weigh 0.75kg of 2.00-4.75mm large granular urea produced by China Overseas Chemical Company and put it into a stainless steel drum with a diameter of 26cm and 4 uniformly distributed 1.5cm high herringbone copy plates. Adjust the drum speed to make the urea in good condition. The state of flow. While rotating, use an electric heater to preheat it to 76-82℃ and keep it warm. 4.60g castor oil containing 70# microcrystalline wax (wherein, the mass percentage of 70# microcrystalline wax is 8.2%) and 2.42g preheated to 100°C

[0030] MDI prepolymer (manufactured by DOW, with a functionality of 2, [NCO] content of 23%) is rapidly coated on the surface of urea at the same time. After 6-7 minutes, apply the same second layer. Then coat the third and fourth layers in sequence. After the coating solution of the fourth layer is cured, the urea is kept for 3-5 minutes to facilitate the maturation ...

Embodiment 2

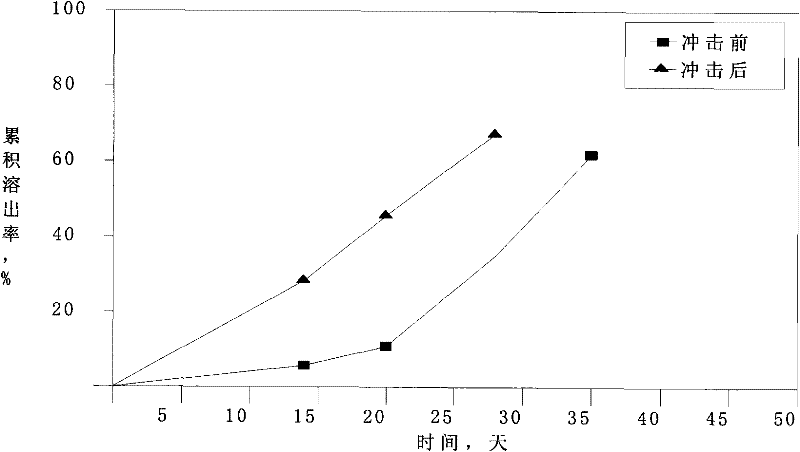

[0033] Example 2: Preparation of polyurethane-coated fertilizer using MDI prepolymer

[0034] Weigh 1.0kg of 2.00-4.75mm 15-15-15 potassium sulfate type compound fertilizer produced by China-Arab Fertilizer Company, and put it into a stainless steel drum with a diameter of 26cm and 4 uniformly distributed 1.5cm high herringbone copy plates. Adjust the rotating speed of the drum to make the compound fertilizer in a good flowing state. While rotating, use an electric heater to preheat it to 80-85°C and keep it warm. 4.60g castor oil containing C30+α olefin (wherein, the mass percentage of C30+α olefin is 5.0%) preheated to 100°C and 2.48g MDI prepolymer (manufactured by DOW, with a functionality of 2, [NCO] content is 18.6%) at the same time quickly spread on the surface of the compound fertilizer. After 6-7 minutes, apply the same second layer. Then coat the 3rd, 4th and 5th layers in sequence. After the coating solution of the fourth layer is solidified, the fertilizer is kep...

Embodiment 3

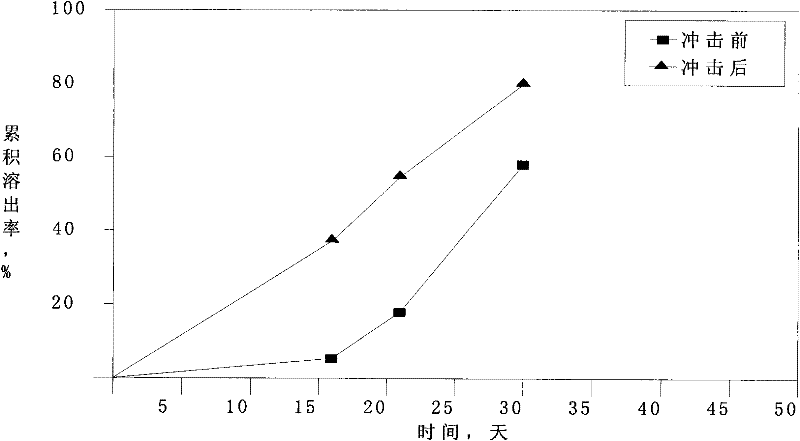

[0035] Example 3. Preparation of polyurethane coated fertilizer using MDI prepolymer

[0036] Weigh 1.0 kg of 2.00-4.75mm 15-15-15 potassium sulfate type compound fertilizer produced by China-Arab Fertilizer Company, and put it into a stainless steel drum with a diameter of 26cm and 4 uniformly distributed 1.5cm high herringbone copy plates, and adjust The rotating speed of the drum makes the compound fertilizer in a good flowing state. While rotating, use an electric heater to preheat it to 80-85°C and keep it warm. Heat the castor oil mixture containing 70# microcrystalline wax and dehydroacetic acid (wherein, the mass percentage of 70# microcrystalline wax is 5.0% and the mass percentage of dehydroacetic acid is 1.0%) on an electric furnace to 100 ℃ preheated to 100 ℃ 4.60g castor oil containing 70# microcrystalline wax (wherein, the mass percentage of 70# microcrystalline wax is 5.0%) and 2.48g MDI prepolymer (manufactured by DOW company, functionality is 2. [NCO] content i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com