Phase change heat storage material and preparation method thereof

A phase change heat storage and main material technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of easy supercooling and phase separation, low latent heat of phase change, low material density, etc., and achieve the preparation method Simple, stable exothermic process, stable performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In this embodiment, the content of main ingredient barium hydroxide (Ba(OH)2.8H2O) is 94.5%, and the content of additive barium chloride is 5.5%. The chemical components used in this embodiment need to be sealed and kept in storage, especially when barium hydroxide is exposed to the air at normal temperature, it is easy to chemically react with carbon dioxide, which affects the performance. The materials used in the present invention can be packed in packages that can meet the sealing requirements when they leave the factory, so it is only necessary to pay attention not to damage the outer package during transportation.

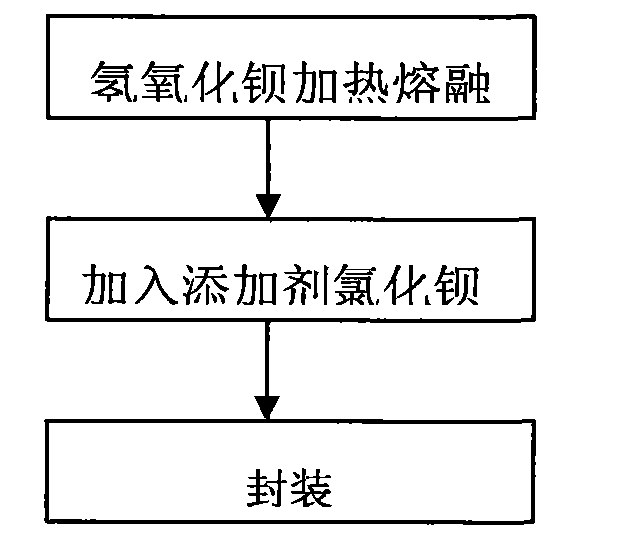

[0025] When making, according to the ingredients, such as figure 1 As shown, put the main material barium hydroxide (Ba(OH)2 8H2O) in the equipment at 85℃~90℃ to heat and melt, then add the additive barium chloride after it is completely melted, and stir evenly, and then The mixture is reheated to make it evenly mixed into a fluid state, and finally p...

Embodiment 2

[0031] In this embodiment, the content of main ingredient barium hydroxide (Ba(OH)2.8H2O) is 93.5%, and the content of additive barium chloride is 6.5%. The chemical components used in this embodiment need to be sealed and kept in storage, especially when barium hydroxide is exposed to the air at normal temperature, it is easy to chemically react with carbon dioxide, which affects the performance. The materials used in the present invention can be packed in packages that can meet the sealing requirements when they leave the factory, so it is only necessary to pay attention not to damage the outer package during transportation.

[0032] When making, according to the ingredients, such as figure 1 As shown, put the main material barium hydroxide (Ba(OH)2 8H2O) in the equipment at 85℃~90℃ to heat and melt, then add the additive barium chloride after it is completely melted, and stir evenly, and then The mixture is reheated to make it evenly mixed into a fluid state, and finally p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition enthalpy | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com