Novel energy-saving emission-reduction environmental-protection method and device

A technology for energy saving, emission reduction, and dyeing method, which is applied in the direction of dyeing method, equipment configuration for processing textile materials, textiles and papermaking, etc. It can solve the problems of printing and dyeing wastewater, increase dyeing cost, increase steam and electricity consumption, etc., and achieve the goal of reducing wastewater Emissions, savings in dyes, chemicals and auxiliaries, and reduction in water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

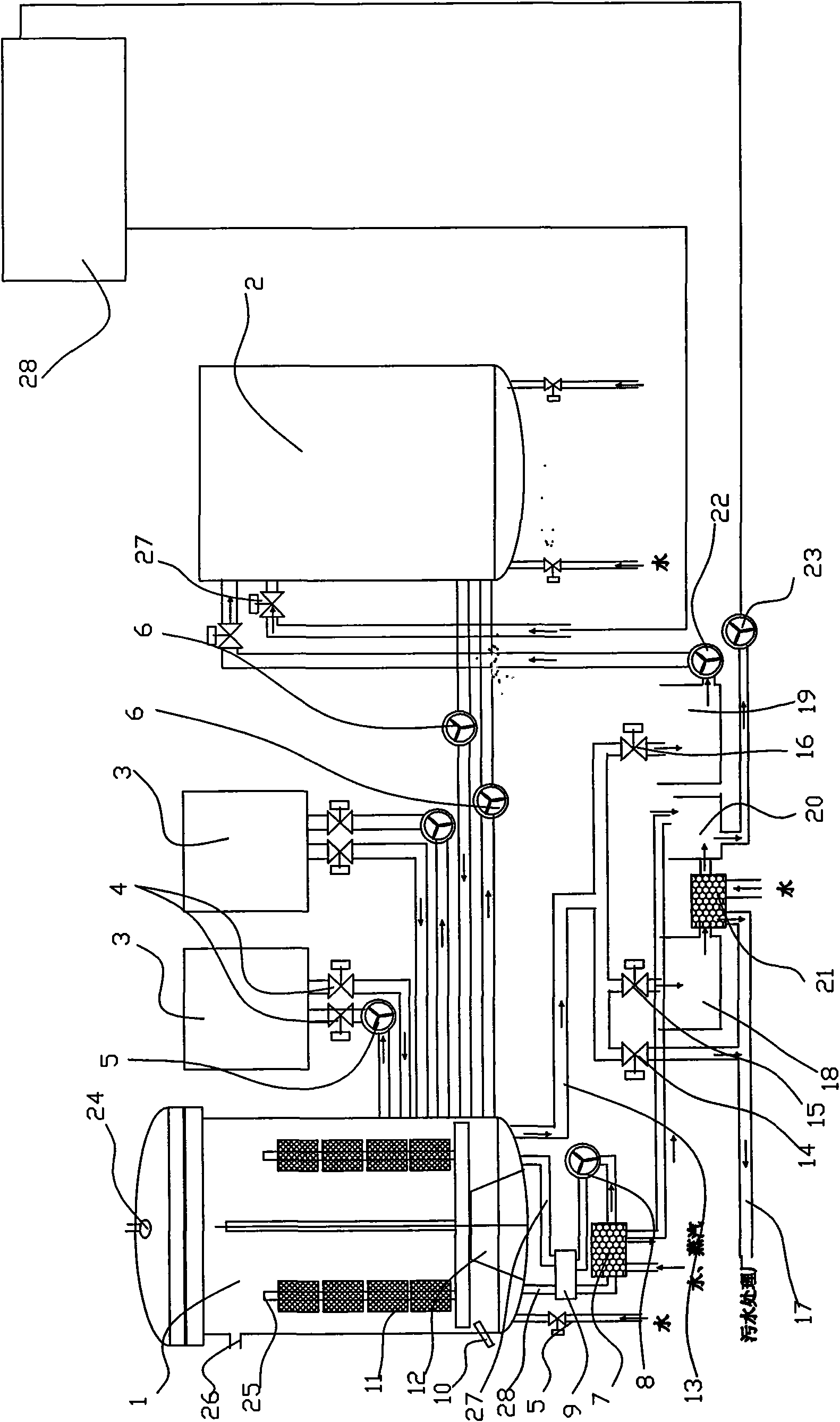

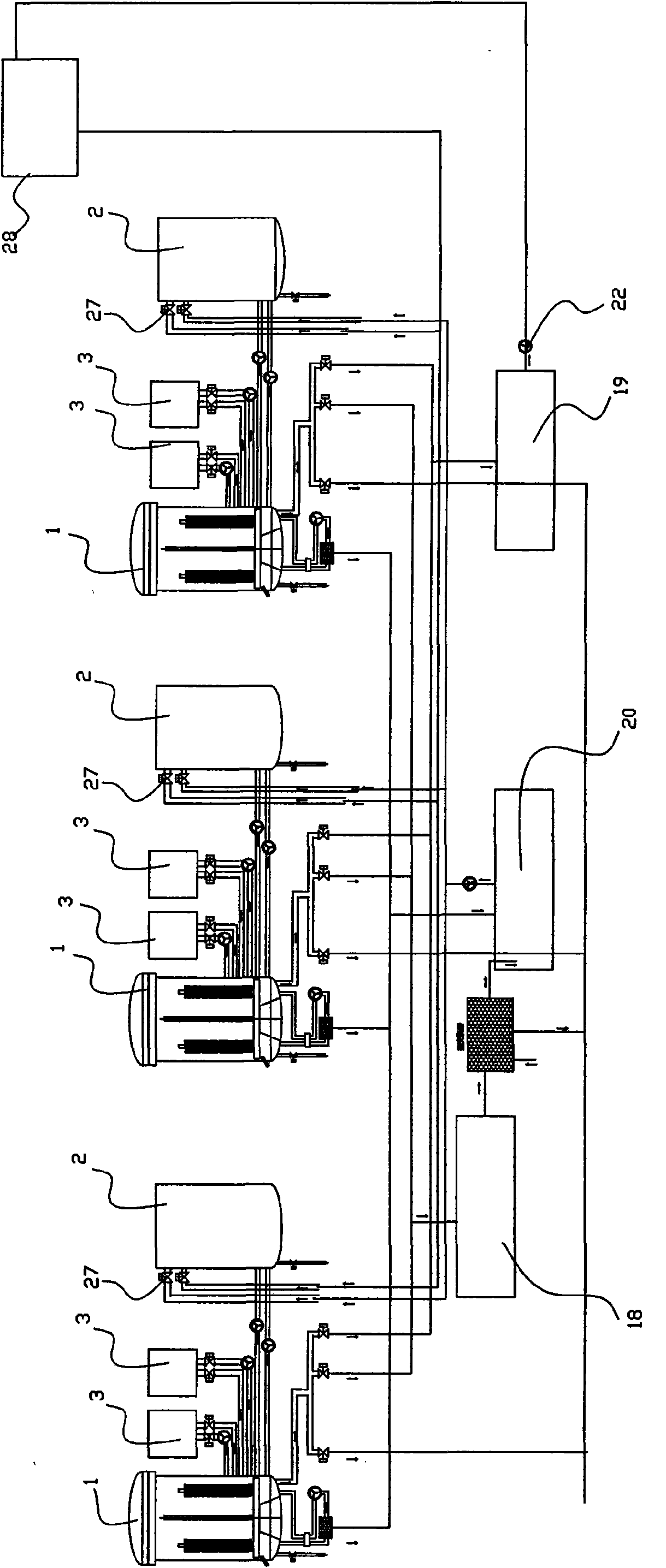

[0016] Now in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0017] The novel energy-saving, emission-reducing, and environmentally-friendly dyeing method of the present invention is realized in this way, including a printing and dyeing process and a post-finishing process. The printing and dyeing process includes rinsing, water washing, pickling, water washing, and dyeing, and the post-finishing process includes water washing, pickling, water washing, and soaping. , water washing, color fixing, and over-softening. The special feature is that when the water level reaches the low water level of 15-25% of the capacity of the dyeing vat, the liquid circulation device with a heat exchanger is started, and the liquid flowing in the liquid circulation device is used at the same time. The yarn fixed on the dyeing creel is processed by flowing from the hollow dyeing creel to the outside. A reversing valve is installed betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com