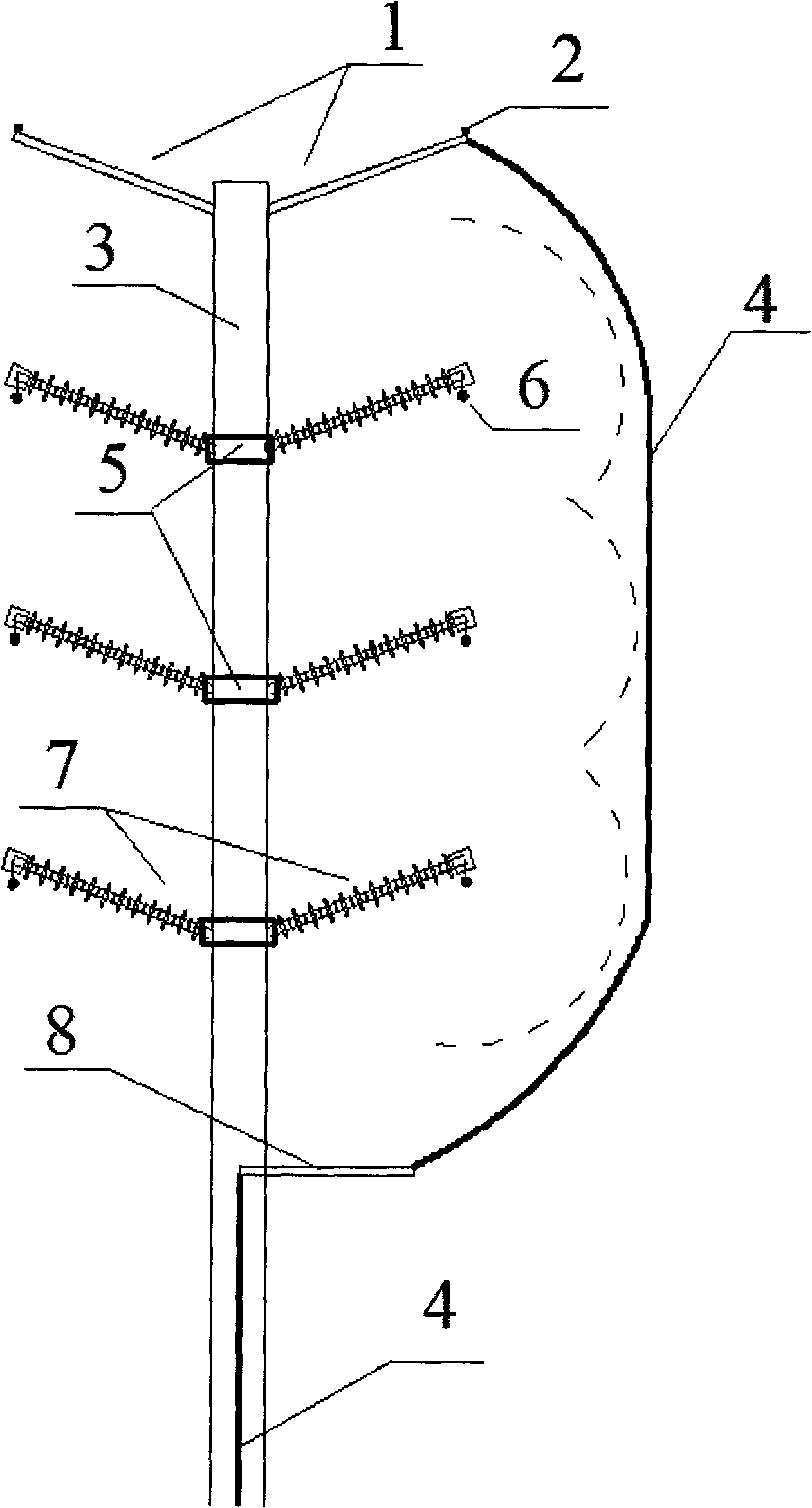

Compound material pole tower

A composite material and tower technology, applied in the connection contact material, tower, grounding wire configuration and other directions, can solve the problems of land acquisition, house demolition cost increase, the number of line failures and other issues, to avoid the decline of insulation performance, reduce Insulated creepage paths, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

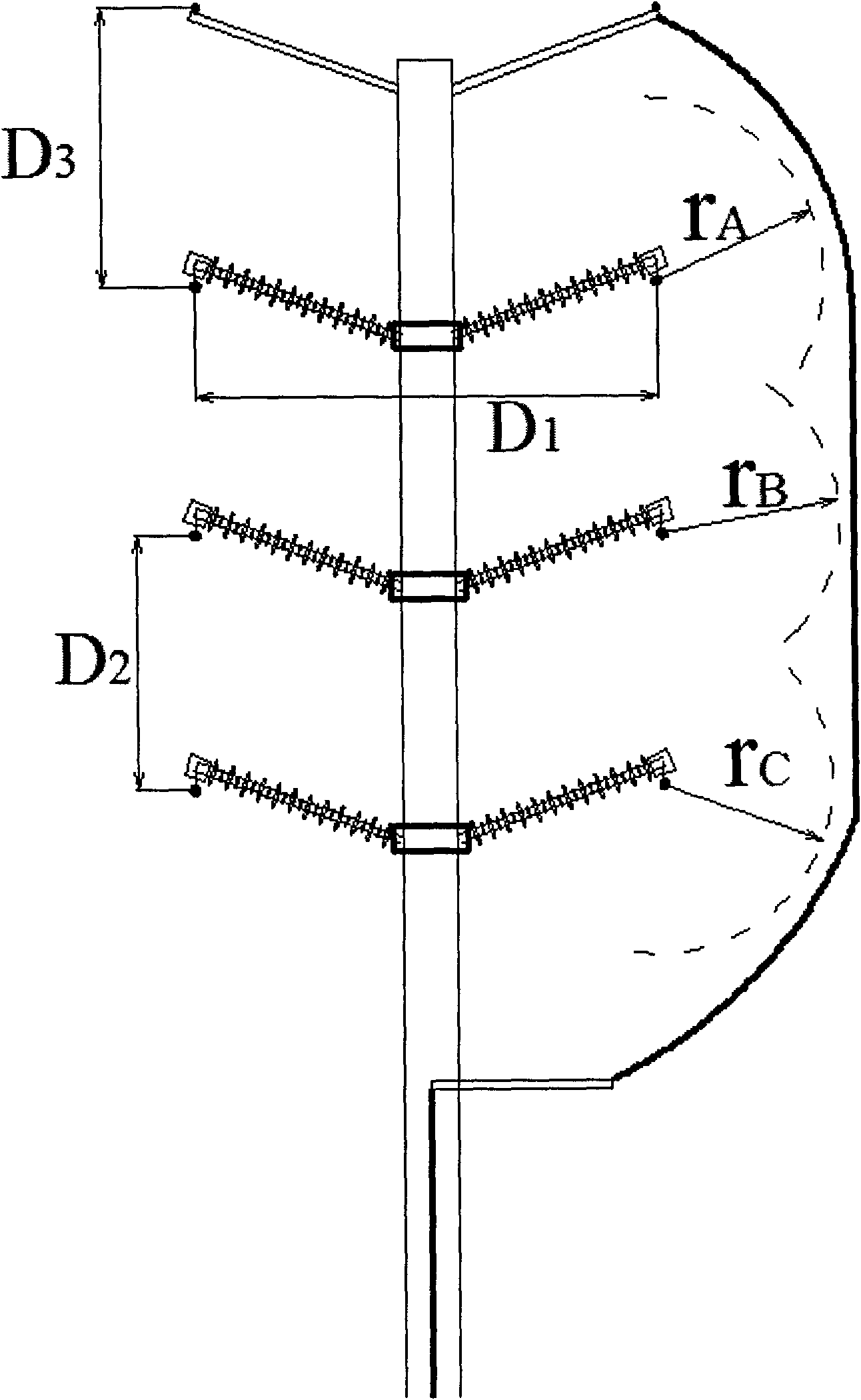

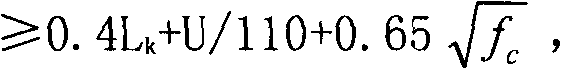

[0025] Example: such as figure 2 Medium composite material towers, taking 110kV line towers as an example, are designed according to the linear tower with a line span of 300m, and the main parameters of the tower can take the following values: D 1 =D 2 = 3.0m, D 3 = 3.0m, r A = 1.2m, r B = r C = 1.5m, the creepage distance of the insulating cross-arm is 3650mm. First of all, the clearance distance of each pole tower meets the design requirements of 110kV line (the minimum phase-to-ground clearance distance is greater than 1.0m, the insulation creepage distance is not less than 3650mm in Class III polluted areas, and the horizontal insulation distance between phases is D 1 satisfy ≥ 0.4 L k + U / 110 + 0.65 f c , Vertical insulation distance between phases D 2 satisfy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com