Multi-point back synchronous injection method of double circular shield tunnel

A synchronous grouting and double-circle shield technology, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problem that it is difficult to separately control the injection pressure and flow rate of the upper and lower pipes, and cannot fill the building void well. It is difficult to allocate the upper and lower two grouting pipes, etc., so as to avoid the difficulty of tunnel deflection control, facilitate on-site construction management, reduce operation difficulty and construction risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The features of the present invention and other related features will be further described in detail below in conjunction with the accompanying drawings through embodiments, so as to facilitate the understanding of those skilled in the art:

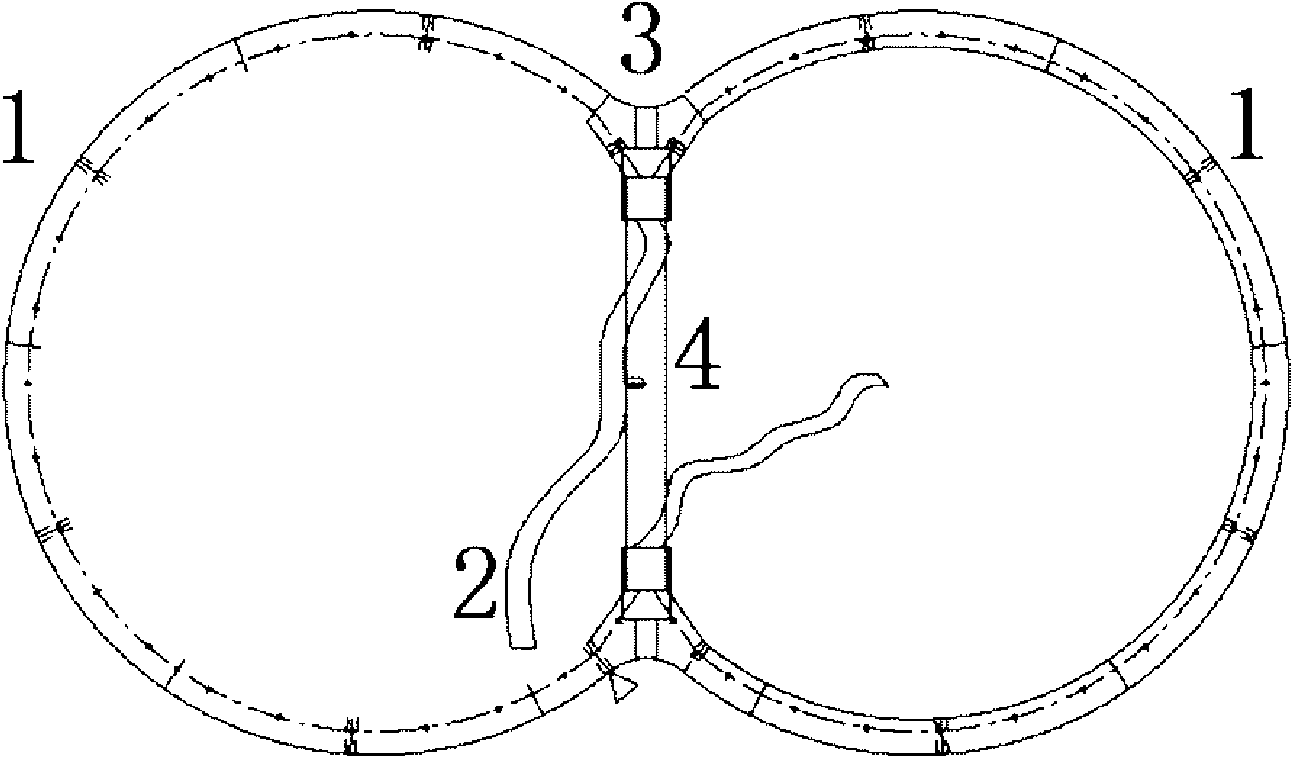

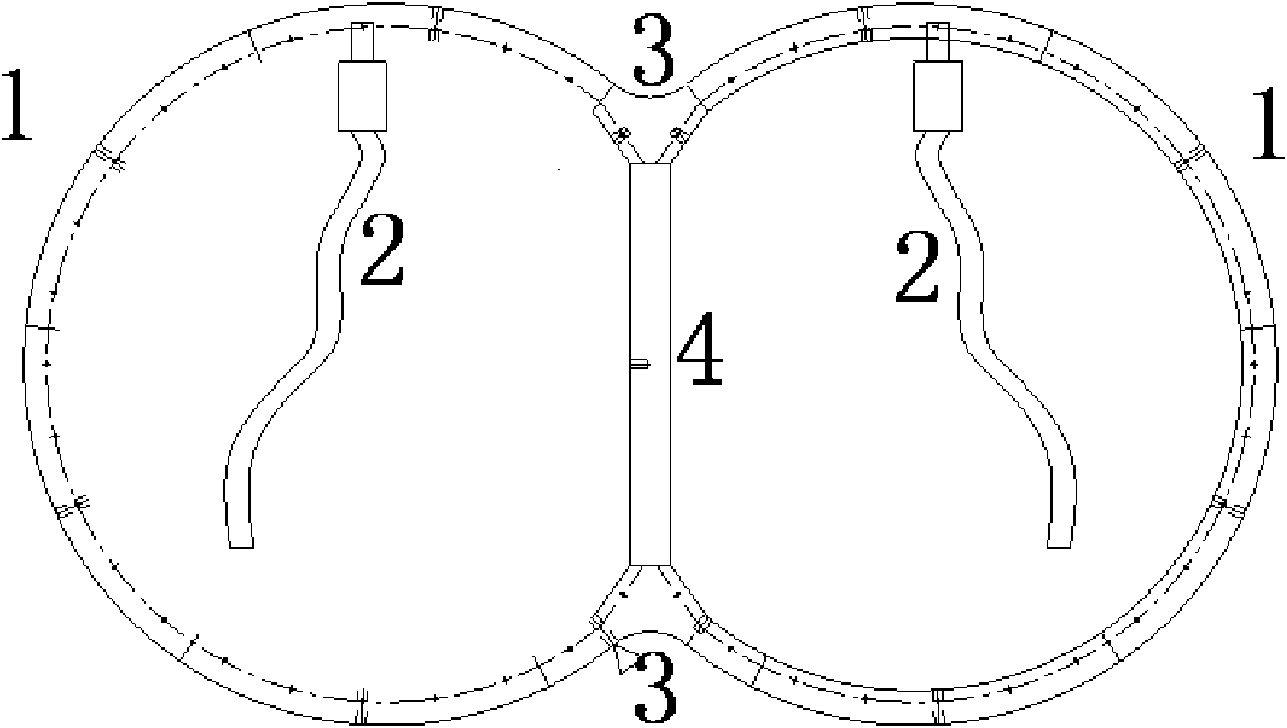

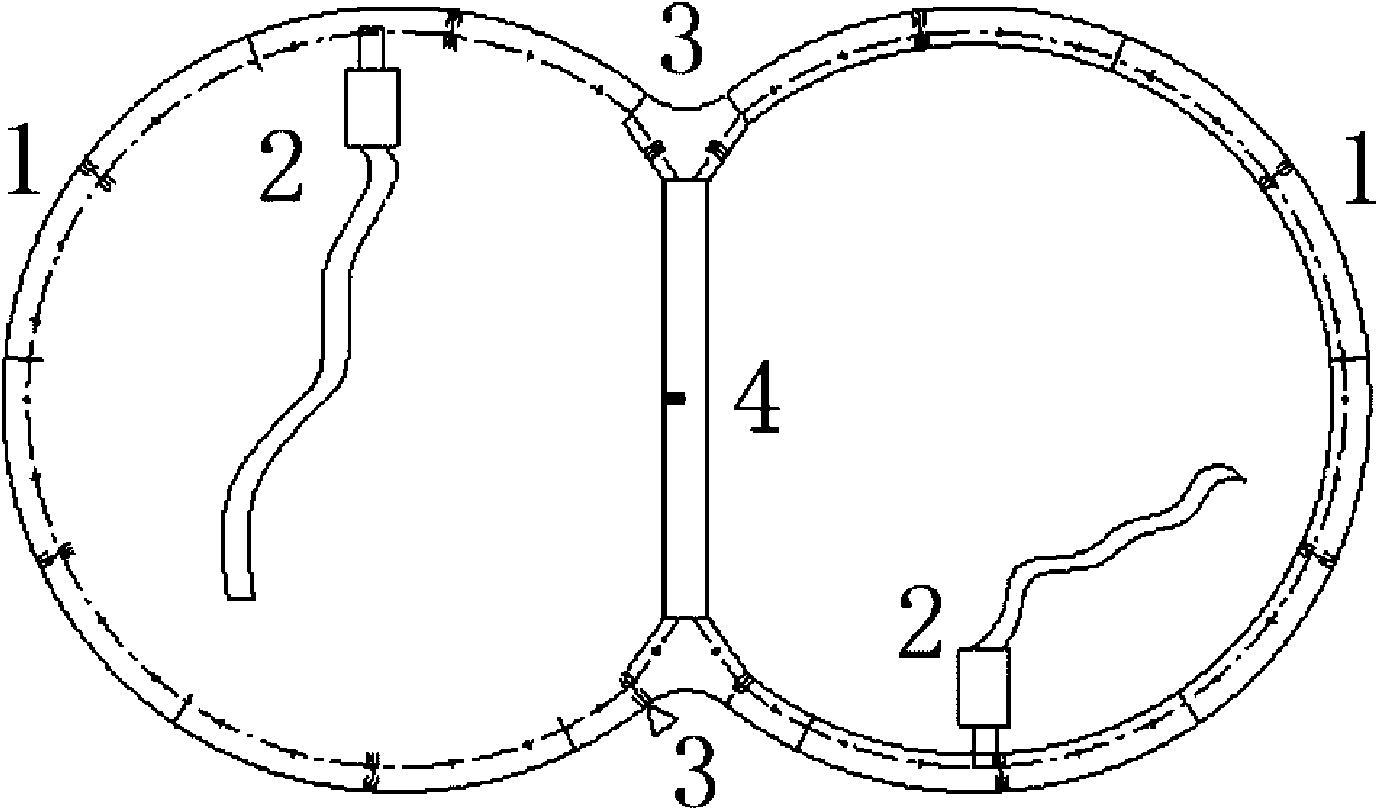

[0019] like image 3 As shown, the labels 1-4 respectively represent: the segment structure 1, the double liquid slurry pump 2, the grouting hole 3, and the center column 4.

[0020] like image 3 Shown, the construction process of the present invention is as follows:

[0021] 1) Establish the artificial neural network prediction and fuzzy logic control model and algorithm for shield construction deformation and the volume of the shield tail building void to be filled, and calculate the construction at the next moment from the known deformation and change of the ground surface (stratum) at the current moment The change amount (control amount) of the controllable parameter is used to determine the synchronous grouting amount. At ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com