System and method for delivering cryogenic fluid

A low-temperature fluid and delivery system technology, applied in container discharge methods, fluid transfer, fluid treatment, etc., can solve problems such as pollution, water accumulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

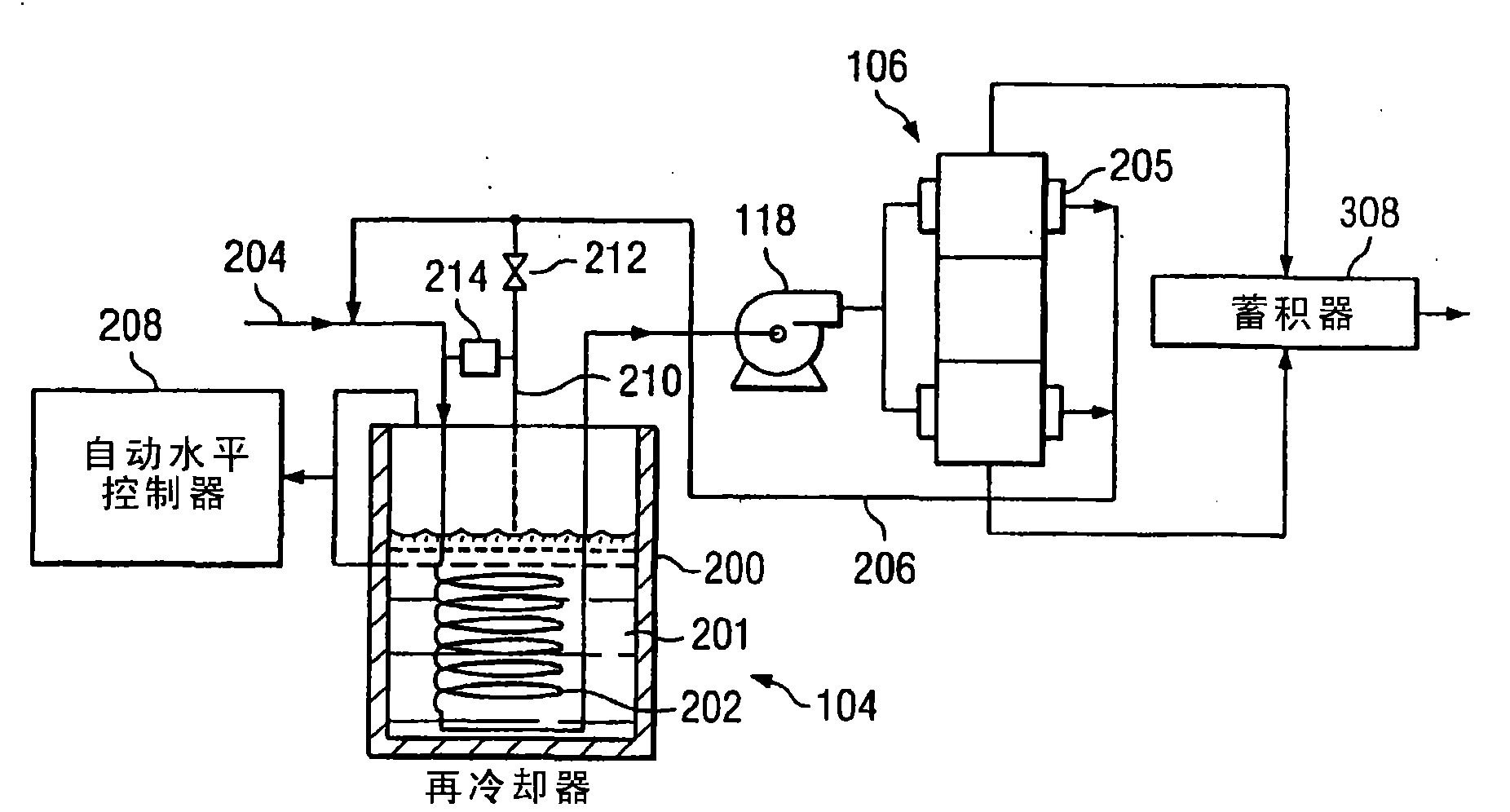

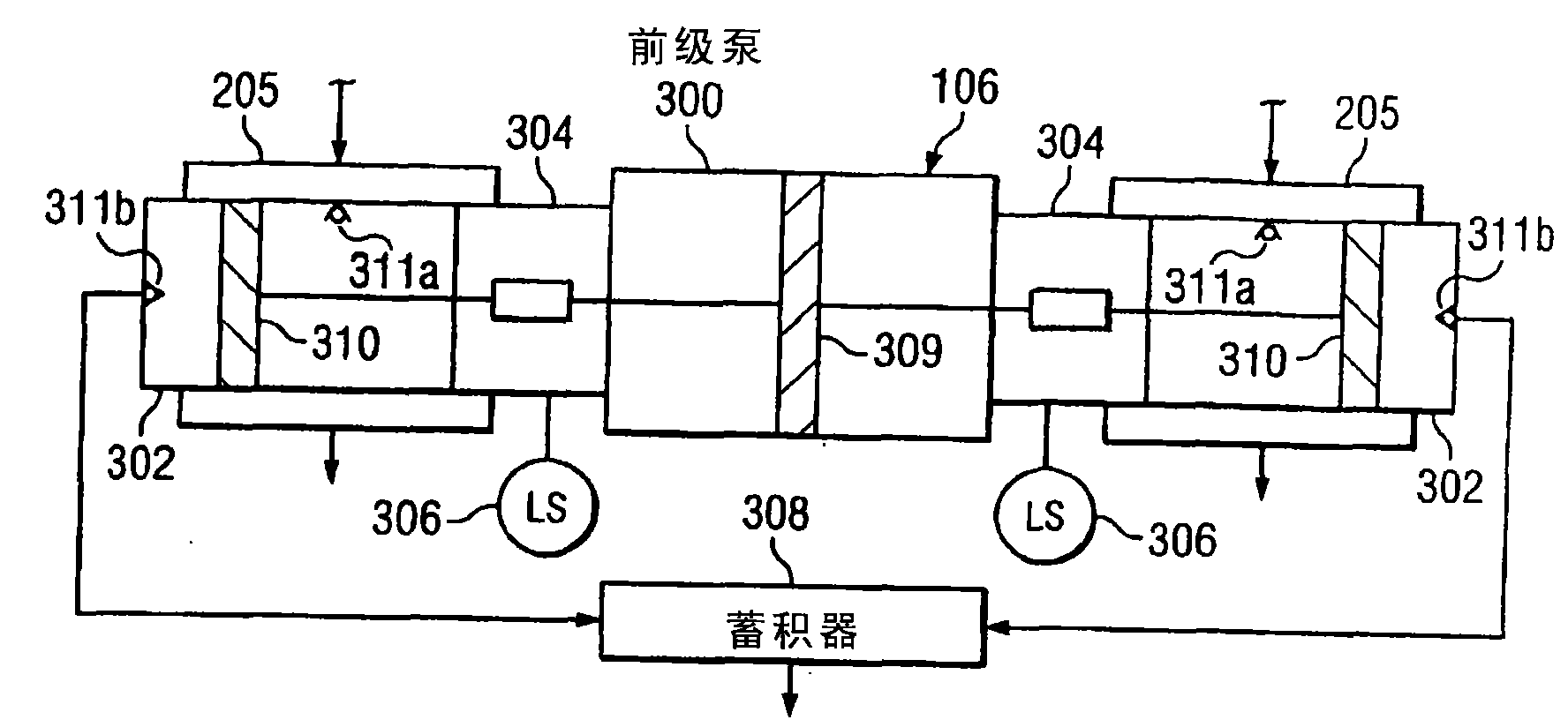

[0019] by referring to the attached Figures 1 to 9B , embodiments of the invention and some of their advantages will be best understood, wherein like numerals are used for like and corresponding parts of the various drawings.

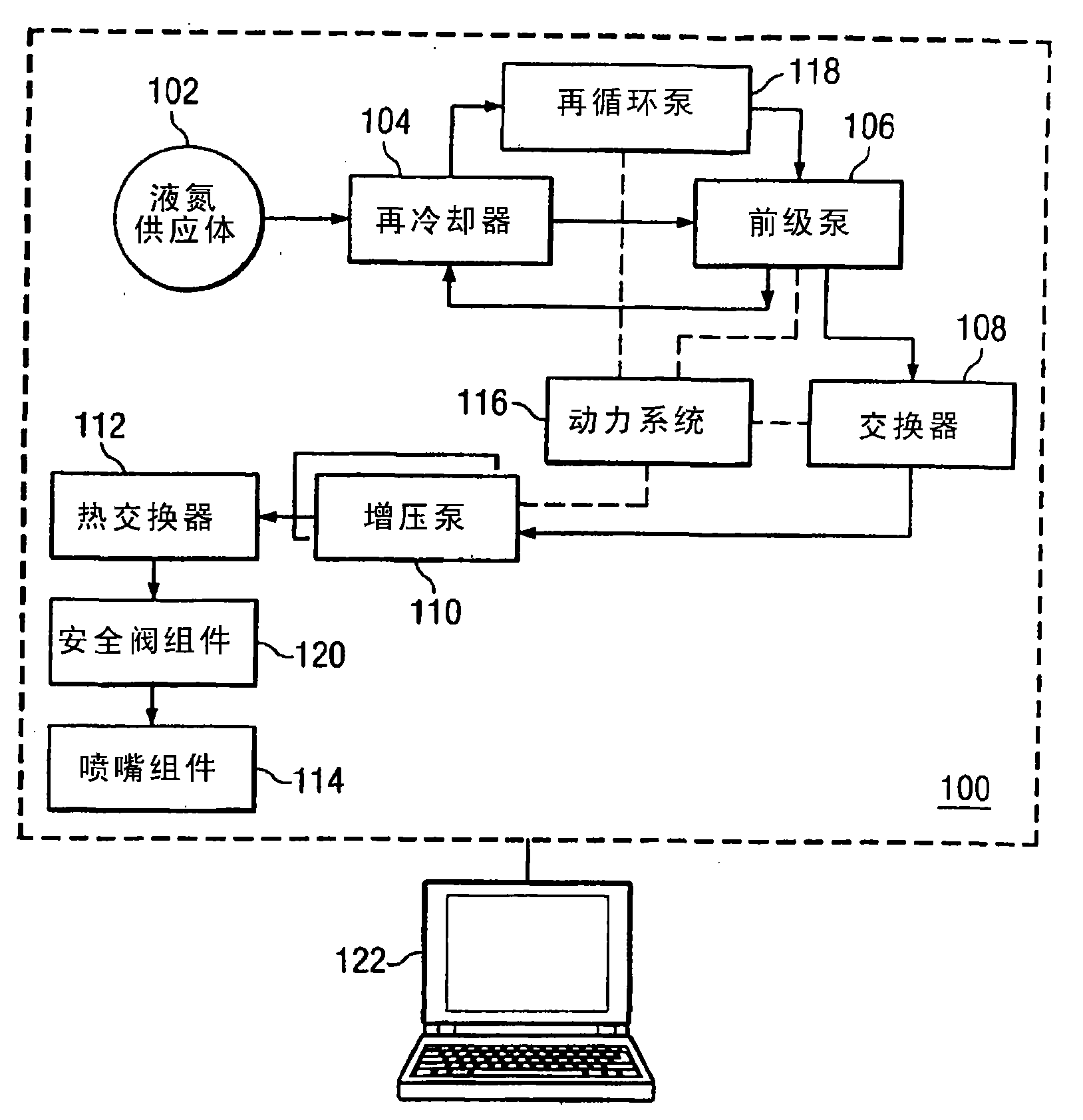

[0020] figure 1 is a functional block diagram of a cryogenic fluid delivery system 100 according to one embodiment of the present invention. In the illustrated embodiment, the delivery system 100 includes a liquid nitrogen supply 102, a subcooler 104, a backing pump 106, an exchanger 108, a pair of booster pumps 110, a heat exchanger 112, a nozzle assembly 114, a power system 116 , recirculation pump 118 , safety valve assembly 120 and controller 122 . However, the present invention also contemplates having more than, less than or different figure 1 The delivery system 100 of those components is shown. In general, the cryogenic fluid delivery system 100 is capable of providing high pressure, high velocity flow of cryogenic fluid to cut, grind, or o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com