Active drying tower system

A drying tower and tower body technology, applied in the field of active drying tower system, can solve the problems of large steam consumption, high power consumption, low drying output, etc., to reduce power consumption and steam consumption, and occupy an area Small size, high drying yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

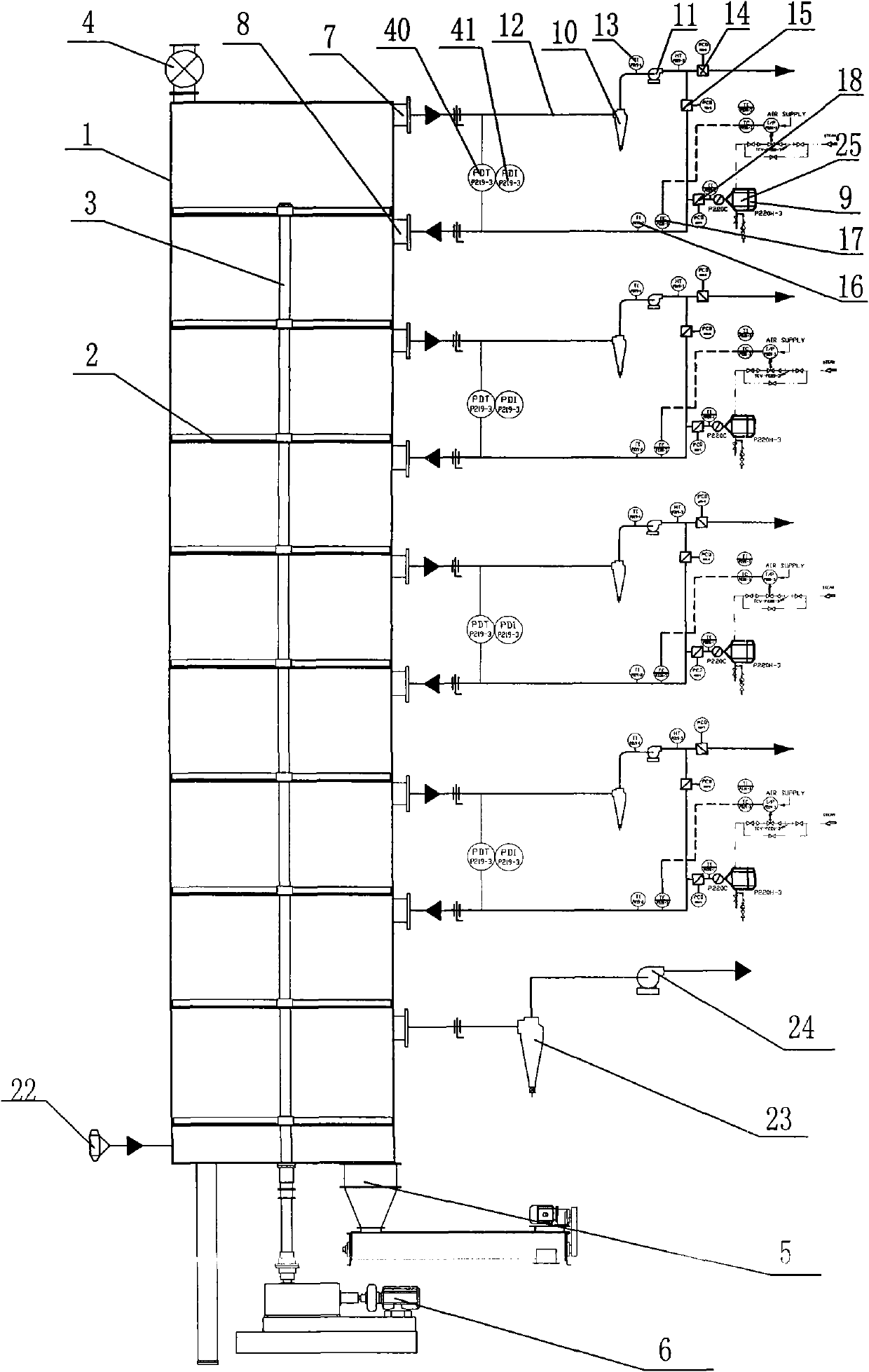

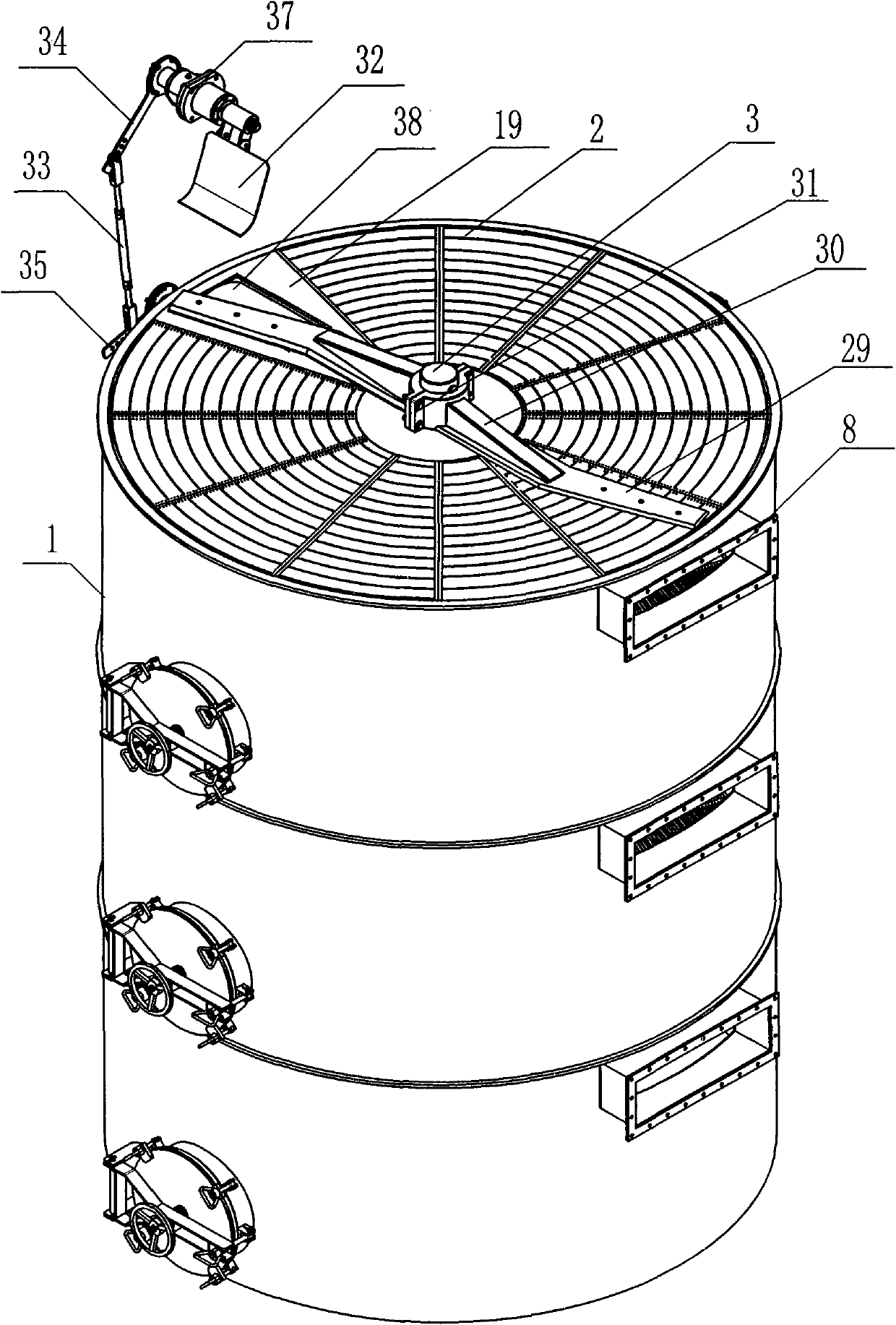

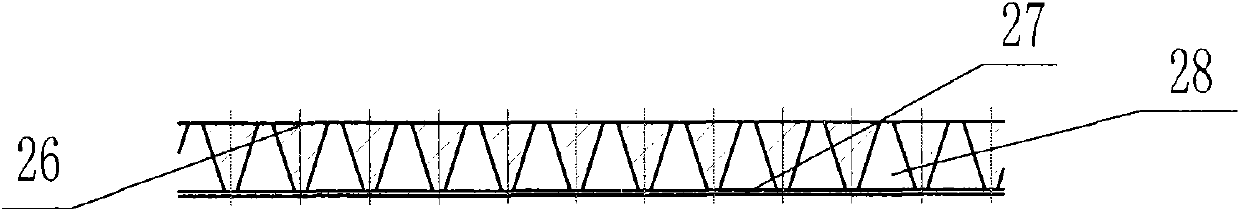

[0018] Further illustrate the present invention in conjunction with accompanying drawing and embodiment, as figure 1 , 2 , 4, the present invention consists of a tower body 1, several layers of drying trays 2 with air holes fixed at equal distances in the tower body 1, each layer of drying trays 2 are provided with mutually dislocated feeding ports, and the movable openings provided on the feeding ports The door mechanism, from the bottom of the tower body, passes through the stirring shaft 3 in the center of the drying trays of each layer, corresponding to the stirring device fixed on the stirring shaft 3 of the drying tray 2 of each layer, and the tower body on the upper and lower sides of the drying trays of each interphase layer from top to bottom The circulating air outlet and inlet ports 7 and 8 provided on the top, each circulating air outlet, inlet 7 and 8 ports are connected to the circulating air duct 12, and the circulating air duct is connected to the circulating d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com