Repulpable adhesive

An adhesive and repulp technology, applied in adhesive types, film/sheet adhesives, non-polymer organic compound adhesives, etc., can solve problems such as reducing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

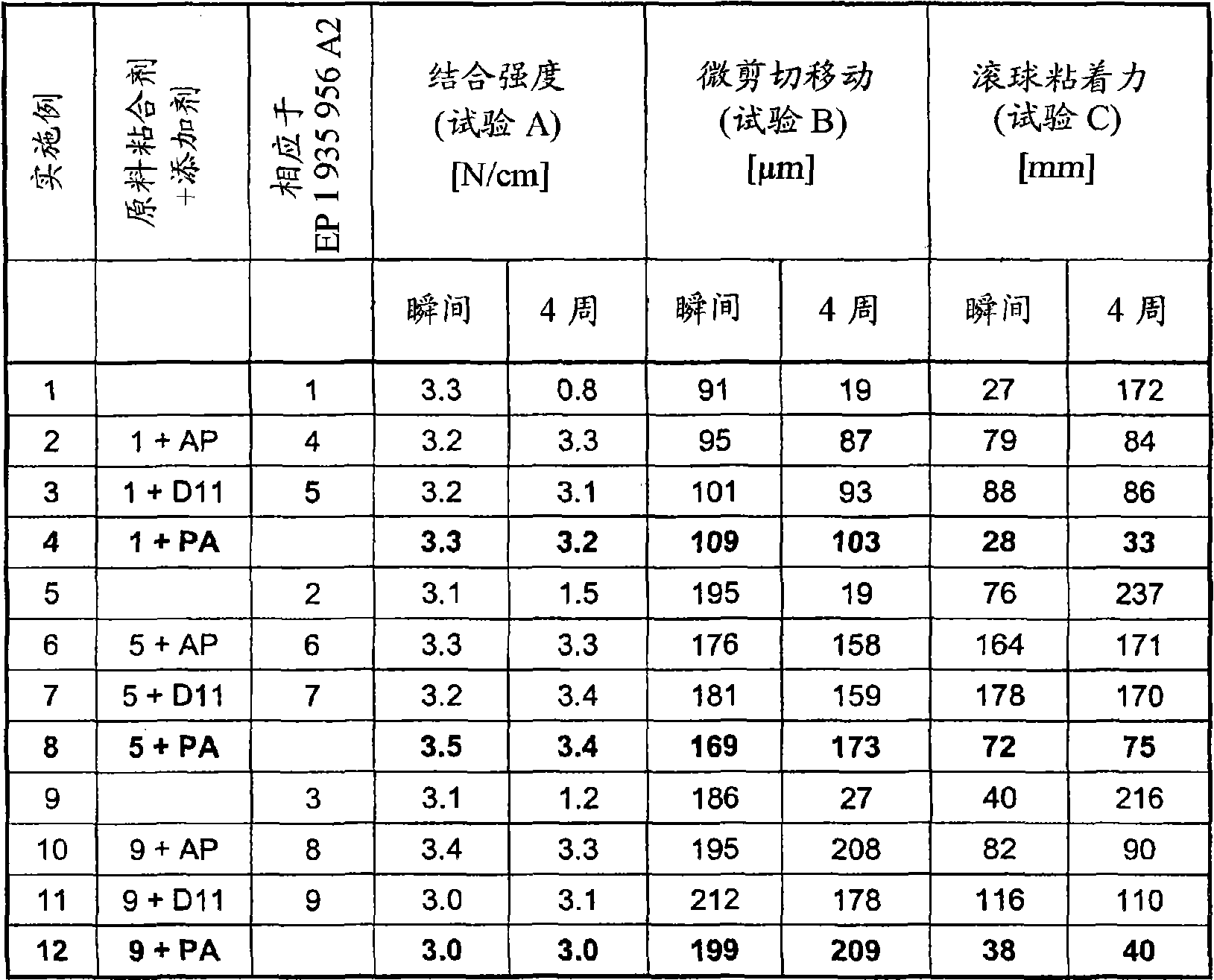

Examples

Embodiment 1

[0052] Example 1: Reference Composition 1

[0053] 599g of the following solution, 397g of polyoxyethylene (15) cocoamine (polyoxyethylene (15) cocoamine) (trade name Ethomeen C-25, Akzo; CAS No.61791-14-8) and 0.70g of bisphenol A dishrunk Glyceryl ether (bisphenol A epichlorohydrin, Mw<700; trade name Epikote 828LVEL, Hexion, CAS No.25068-38-6) mixed, the solution is: 47% acrylic acid, 48% butyl acrylate and 5 A 30% concentration solution of a radically polymerized scaffold polymer consisting of % vinylcaprolactam in a 1:1:1 mixture of water, isopropanol and acetone.

[0054] The scaffold polymer is also characterized by a mass average molar mass Mg of 9×10 5 g / mol, and a polydispersity of 8.

Embodiment 2

[0055] Example 2: (base polymer and additives from Example 1)

[0056] The composition described in Example 1 was additionally mixed with 17.3 g of diammonium hydrogen phosphate.

Embodiment 3

[0057] Example 3: (base polymer and additives from Example 1)

[0058] The composition described in Example 1 was additionally mixed with 17.3 g of a commercially available high complexing sodium polyphosphate and sodium alkylphosphonate preparation (trade name Kappafos D11, manufacturer: Kapp-Chemie, according to the manufacturer Provides a calcium-binding capacity of 120 mg CaO / g) mix.

PUM

| Property | Measurement | Unit |

|---|---|---|

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com