Transparent solid soap

A transparent solid and solid soap technology, applied in the direction of transparent solid soap/detergent, soap with clearly defined chain length, shaped soap, etc., to achieve the effects of high transparency, good foaming and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

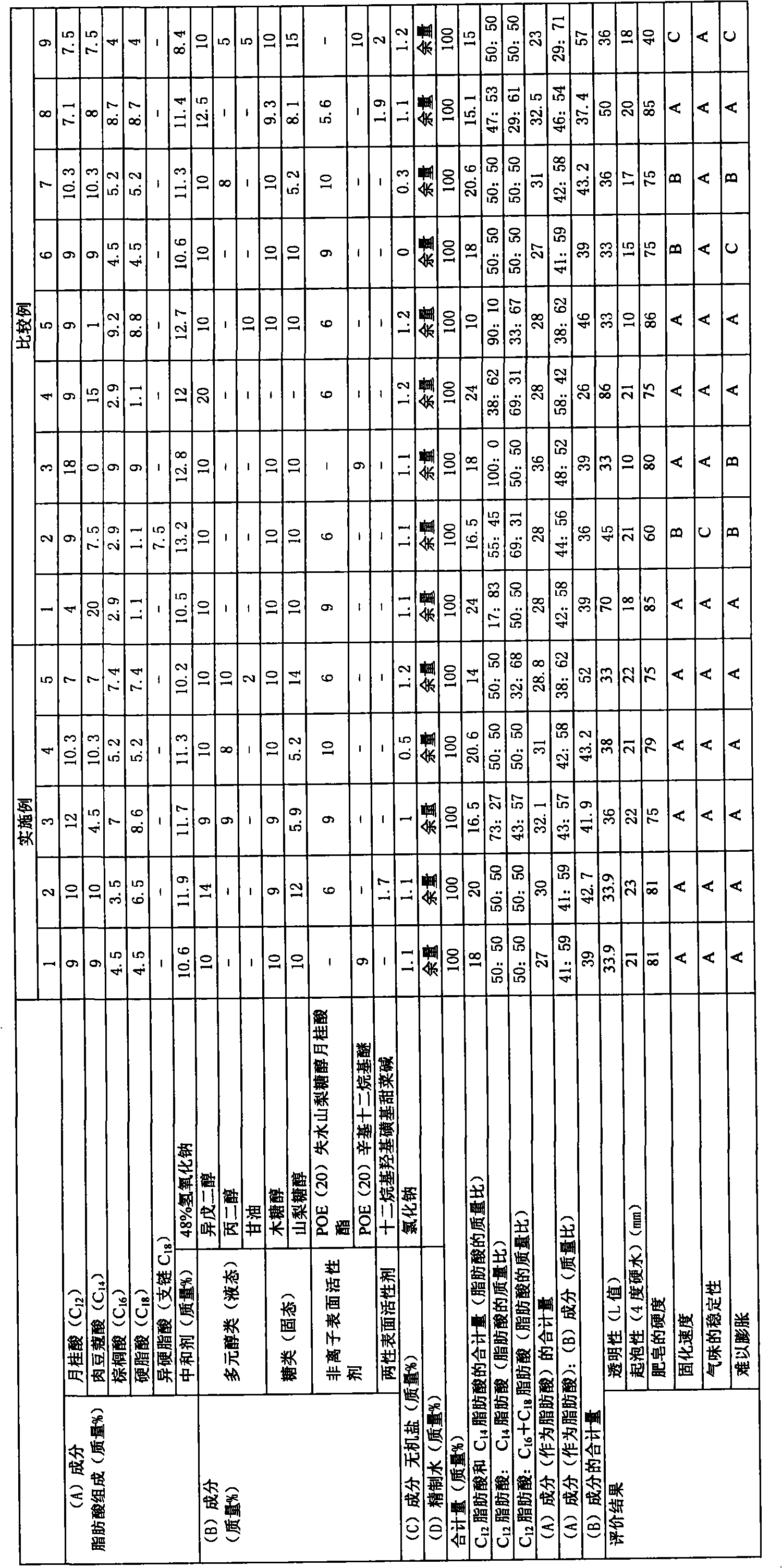

[0052] The fatty acids listed in Table 1, polyhydric alcohols and surfactants which are liquid at normal temperature were mixed and melted at 80°C. A 48% aqueous sodium hydroxide solution diluted with 5% by mass of water was slowly added dropwise thereto for neutralization. After becoming transparent and homogeneous, a solution obtained by mixing sodium chloride, sugar, and purified water separately and heating to 80°C was added to the neutralized solution, and mixed at 80°C for 15 minutes to obtain a soap composition in a molten state .

[0053] Using the obtained soap composition, it evaluated by the following method. The results are shown in Table 1.

[0054] (Evaluation method)

[0055] 1. Transparency

[0056] 5 mL of the soap composition in the molten state was poured into a Balance Dish (35×35×10 mm) at 80° C., left to cool, and then solidified solid soap was taken out. The time required for cooling and solidification at room temperature (25°C) is about 20 minutes. ...

Embodiment 2~5 and comparative example 1~9

[0072] Except having used the composition shown in Table 1, it carried out similarly to Example 1, and obtained the soap composition. Table 1 shows the results of evaluation by the same method as in Example 1.

[0073] Table 1

[0074]

Embodiment 6~15

[0076] In the same manner as in Example 1, a soap composition having the following composition was obtained. The same good evaluation results as in Example 1 were shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com