High-precision gas mixing system and method

A gas mixing, high-precision technology, applied in mixers, chemical instruments and methods, dissolution, etc., can solve problems such as unsatisfactory combustion effects and hazards, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

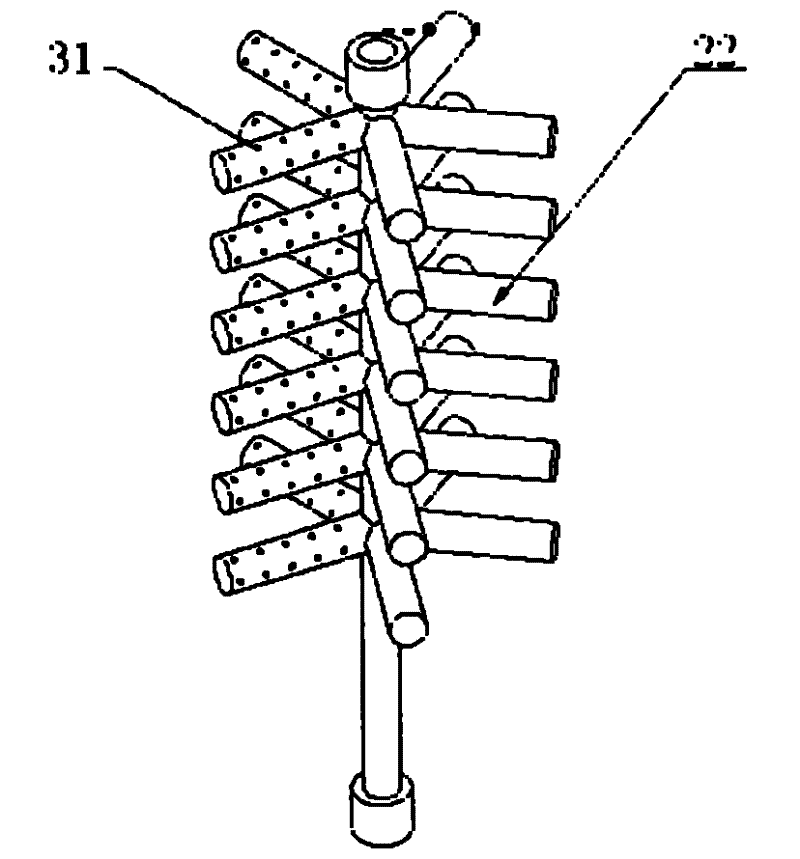

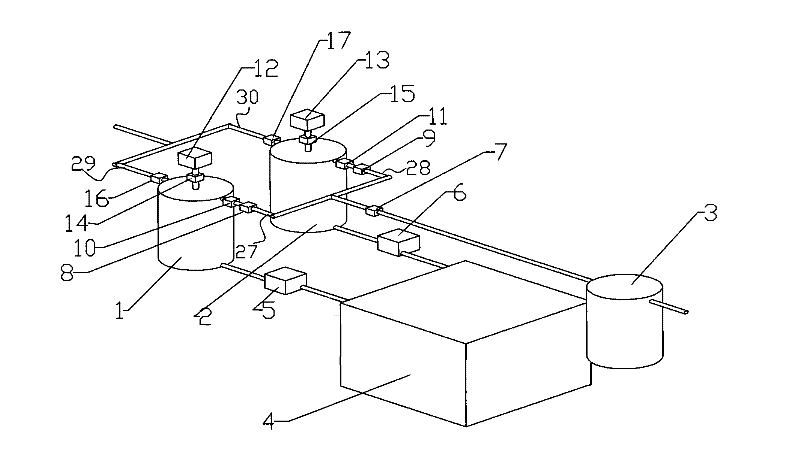

[0034] 1-gas distribution tank I; 2-gas distribution tank II; 3-buffer gas tank; 4-water tank; 5-water pump I; 6-water pump II; 7-stabilizing valve; 8-gas concentration sensor I; 9-gas Concentration sensor II; 10-check valve A; 11-check valve B; 12-inverter blower I; 13-inverter blower II; 14-check valve C; 15-check valve D; 16-check valve E ;17-one-way valve F; 21-intake pipe; 22-rectifier branch pipe; 23-rolling bearing; 24-upper liquid level trigger device I; 25-lower liquid level trigger device II; 27-connecting pipe A; C; 29-connection pipe B; 30-connection pipe D; 31-air outlet channel.

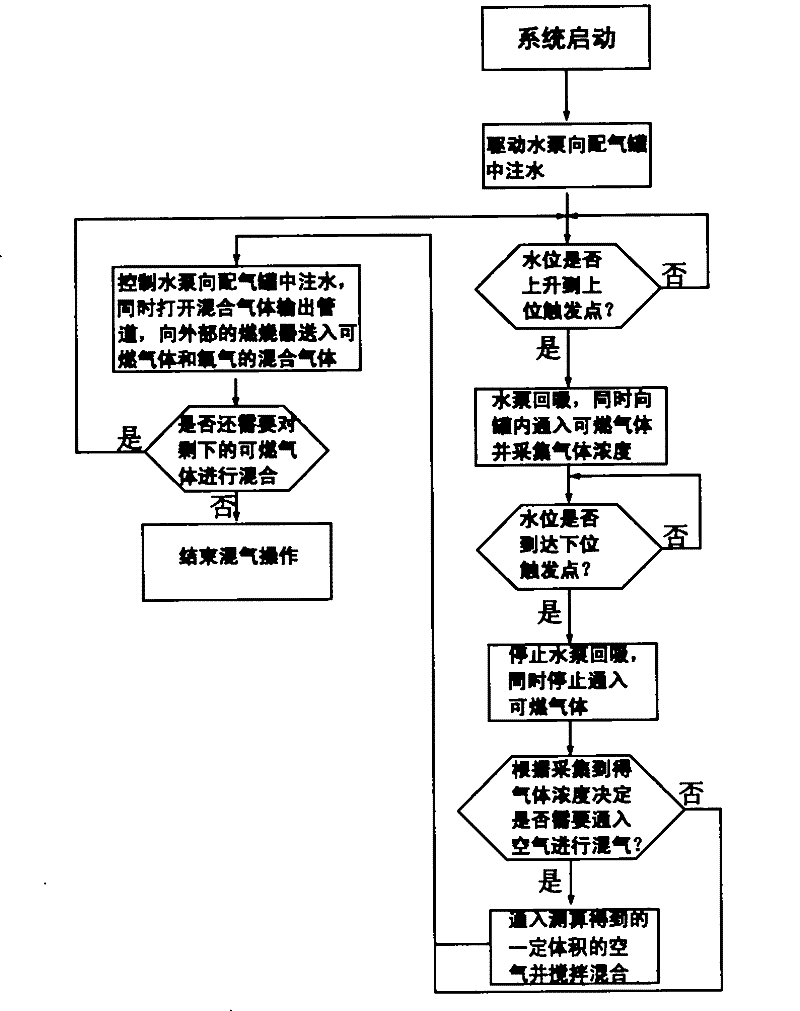

[0035] Such as figure 1 Shown, the high precision gas mixing system of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com